Powder Coating: Durable Color Meets Functional Protection

Anodizing is an electrochemical process that enhances metal surfaces by forming a controlled oxide layer. It improves corrosion resistance, wear durability, and visual appeal—especially for aluminum components. Suitable: Aluminum, titanium, magnesium, zinc Not Recommended: Carbon steel, stainless steel (unless pre-treated), plastics At SOMI, anodizing is more than protection—it’s precision with personality. We offer custom color-matched finishes, hybrid treatments, and aerospace-grade durability for components that perform and impress.⚙️ Anodizing: Durable Beauty Through Electrochemical Precision

🧩 What Is Anodizing?

🔁 Process Workflow

🧪 Common Types of Anodizing

Type

Description

Oxide Thickness

Type I (Chromic Acid)

Thin, soft layer for aerospace

~0.5–2.5 μm

Type II (Sulfuric Acid)

Standard decorative finish

~5–25 μm

Type III (Hard Anodizing)

Thick, wear-resistant layer

~25–150 μm

🎨 Color & Finish Options

🎯 Application Areas

💡 Technical Features

🔍 Pros vs. Cons

Advantages

Limitations

Durable oxide layer

Limited to non-ferrous metals

Vibrant, fade-resistant colors

Requires precise control

Lightweight protection

Not ideal for steel

Excellent paint adhesion

Color depends on alloy

🛠️ Compatible Materials

🔗 Related Surface Treatments

Process

Comparison to Anodizing

Electroplating

Metal layer added; better conductivity

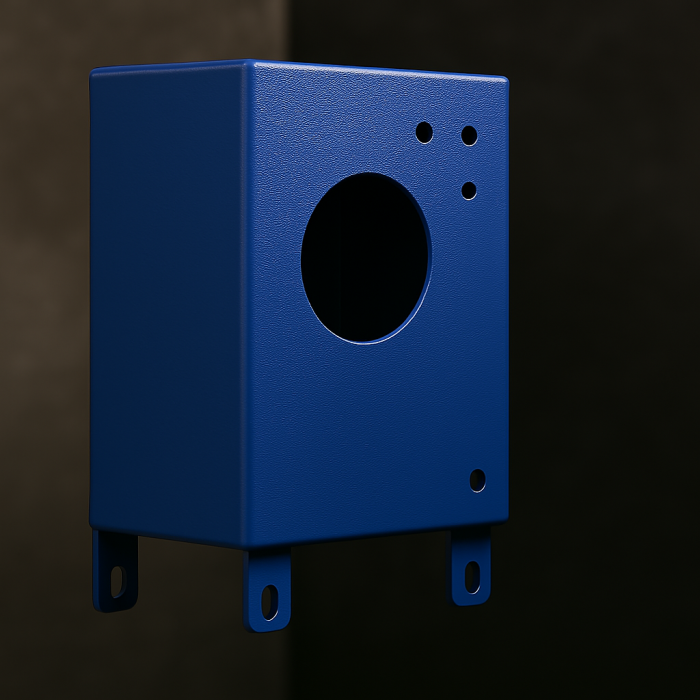

Powder Coating

Thicker, flexible finish

Passivation

Chemical protection for stainless steel

Electroless Plating

Uniform metal layer on non-conductive surfaces

💬 SOMI's Surface Engineering Vision

- Loading...

We hope to discuss potential cooperation opportunities with you and ask you to provide quotation information for your project. Looking forward to your reply and working with you to promote the success of your project!

- *Name

- *Mobile Phone

- *Title

- *Content