Electroplating: Elevating Metal Surfaces with Precision & Performance

Electroplating is a transformative surface treatment process where a thin layer of metal is deposited onto a substrate using electrical current. It improves durability, corrosion resistance, and aesthetics. Suitable: Steel, brass, copper alloys, aluminum (with prep), zinc Not Recommended: Plastics (unless metallized), porous metals At SOMI, we don't just protect metal—we empower it. Our electroplating solutions combine endurance with aesthetics, turning your parts into high-performance art.⚙️ Electroplating: Elevating Metal Surfaces with Precision & Performance

🧩 What Is Electroplating?

🔁 The Process Workflow

🧪 Common Types of Electroplating

Type

Base Metal

Benefits

Applications

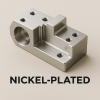

Nickel

Nickel

Corrosion resistance, wear protection

Automotive, electronics

Chrome

Chromium

Mirror finish, hardness

Bathroom fixtures, bike parts

Zinc

Zinc

Rust prevention

Fasteners, bolts

Gold

Gold

Luxury appearance, conductivity

Jewelry, electronics

Copper

Copper

Base layer, conductivity

PCBs, decorative items

🎯 Application Areas

💡 Technical Features

🔍 Pros vs. Cons

Advantages

Limitations

Corrosion & wear protection

Hazardous chemicals involved

Visual enhancement

Not ideal for all shapes

Improved conductivity

Requires pre-treatment

Cost-effective mass production

Waste management required

🛠️ Compatible Materials

💬 Surface Engineering Meets Signature Shine

- Loading...

We hope to discuss potential cooperation opportunities with you and ask you to provide quotation information for your project. Looking forward to your reply and working with you to promote the success of your project!

- *Name

- *Mobile Phone

- *Title

- *Content