Unlocking Superior Product Design: 10+ Strategic Benefits of Overmolding Injection Molding

In today's competitive market, product designers and engineers are constantly challenged to create products that are not only functional but also durable, ergonomic, and aesthetically pleasing. Overmolding, a sophisticated injection molding process, has emerged as a key solution to meet these multifaceted demands. By seamlessly bonding multiple materials—typically a rigid substrate and a soft, flexible thermoplastic elastomer (TPE)—into a single part, overmolding opens up a world of design possibilities. Let's delve into the strategic advantages that make this technique indispensable across various industries.

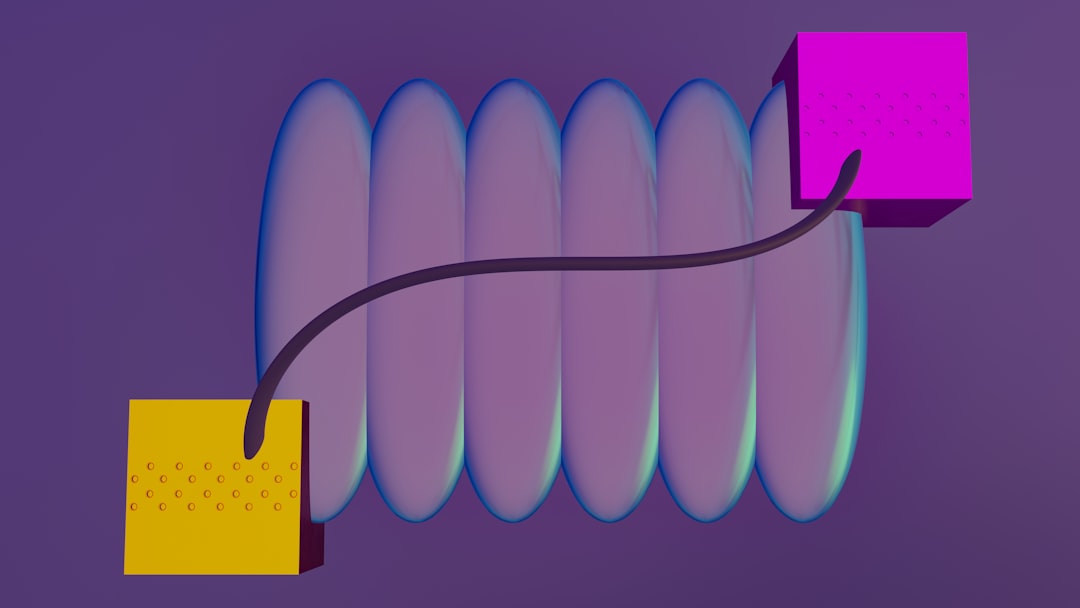

What Exactly is Overmolding?

Overmolding is a multi-step manufacturing process where a pre-molded part, known as the substrate, is placed into a second mold. A different material is then injected into, onto, or around the substrate. This process creates a strong chemical or mechanical bond, resulting in a single, robust, multi-material component. It’s the secret behind the soft-grip handle on your power drill and the waterproof seal on your wearable fitness tracker.

1. Drastically Improve Ergonomics and Grip

The most recognizable benefit of overmolding is the ability to add soft, tactile grips to rigid products. A layer of TPE over a hard plastic handle transforms the user experience. This provides a non-slip, comfortable surface that reduces user fatigue and increases safety, especially in wet conditions or for tools requiring precise control.

2. Integrate Waterproof and Dustproof Seals

Overmolding can create built-in gaskets and seals that are perfectly integrated into a part. This eliminates the need for separate o-rings or manually applied sealants, which can be prone to failure or incorrect assembly. The result is a highly reliable, durable seal that provides superior protection against water and dust ingress for electronics, outdoor equipment, and medical devices.

3. Enhance Shock Absorption and Vibration Dampening

By encapsulating a rigid component with a soft, rubber-like material, products gain excellent shock absorption and vibration-dampening properties. This is crucial for protecting sensitive internal electronics from drops and impacts, reducing operational noise in machinery, and improving the overall durability and lifespan of the product.

4. Boost Aesthetic Appeal and Brand Identity

Overmolding provides immense design freedom to enhance a product's visual appeal. It allows for the use of multiple colors and textures on a single part without resorting to secondary painting or coating operations. This can be used to create distinctive branding elements, color-code functional areas, and give a product a premium look and feel that makes it stand out on the shelf.

5. Increase Product Durability and Longevity

The strong bond created during the overmolding process results in a component that is more robust than a multi-part assembly. It protects the underlying substrate from impact, abrasion, and environmental factors like chemicals and UV radiation. This inherent durability translates to a longer product life and lower warranty claims.

6. Reduce Assembly Steps and Lower Manufacturing Costs

While the initial tooling investment can be higher, overmolding delivers significant long-term cost savings. By combining multiple components into one, it eliminates the need for secondary assembly steps such as gluing, screwing, or snapping parts together. This reduces labor costs, simplifies the supply chain, speeds up production time, and minimizes the risk of assembly errors.

7. Provide Superior Electrical Insulation

Functional safety is another key advantage. Overmolding is an effective method for encapsulating electrical components or creating insulating handles for tools. The overmolded material can be chosen for its dielectric properties, providing a reliable barrier that protects users from electrical shock and shields components from environmental interference.

8. Expand Design Freedom and Enable Complex Geometries

Overmolding allows engineers to design complex, multi-functional parts that would be impossible or prohibitively expensive to produce with traditional methods. It facilitates the combination of materials to achieve specific performance characteristics in targeted areas of a part, all within a single molding cycle.

9. Achieve Material Synergy for Optimized Performance

The process enables the combination of the best properties of different materials. You can pair the structural strength of a rigid plastic or metal substrate with the flexibility, chemical resistance, or tactile feel of an elastomer. This synergy allows for the creation of truly high-performance parts optimized for their specific application.

| Substrate Material | Compatible Overmold Material | Key Benefits |

|---|---|---|

| Polycarbonate (PC) | Thermoplastic Polyurethane (TPU) | High Impact Resistance, Clear Substrate |

| ABS | Thermoplastic Elastomer (TPE) | Good Adhesion, Cost-Effective |

| Glass-Filled Nylon | Santoprene™ (TPV) | High Strength, Chemical Resistance |

| Metal (e.g., steel, aluminum) | TPE, TPU, Silicone | Electrical Insulation, Vibration Dampening |

10. Key Industries Leveraging Overmolding

The benefits of overmolding have been embraced across a wide range of sectors:

- Consumer Electronics: Creating sealed, durable, and ergonomic housings for smartphones, remote controls, and wearables.

- Medical Devices: Manufacturing biocompatible and sterilizable surgical instruments, grips, and patient-contact devices with soft, comfortable surfaces.

- Automotive: Producing interior components with a premium feel, as well as exterior seals, gaskets, and vibration-dampening parts.

- Industrial & Power Tools: Designing robust, non-slip handles that can withstand harsh job site conditions.

Choosing the Right Overmolding Partner

To fully capitalize on these benefits, it's crucial to partner with an experienced injection molder. A deep understanding of material compatibility, mold design, and process control is essential for achieving a strong, reliable bond and a high-quality finished product. An expert partner can guide you through material selection, design for manufacturability (DFM), and process optimization to ensure your project's success.

In conclusion, overmolding is far more than just adding a soft grip to a part; it's a strategic manufacturing choice that enhances performance, quality, and market appeal while often reducing overall production costs.