The Role of Prototyping in Precision Metal Stamping for Manufacturers

As metal stamping parts manufacturers, we understand the critical role prototyping plays in bringing innovative designs to life. It's about transforming raw materials into precise components that meet stringent specifications. Prototyping in precision metal stamping is not just an optional step; it's a strategic imperative that allows us to refine designs, validate performance, and ultimately deliver superior products to the market faster and more cost-effectively. Engaging in thoughtful Metal Stamping for Manufacturers practices from the outset ensures a smoother path from concept to full-scale production.

Understanding the Essence of Prototyping for Metal Stamping Parts Manufacturers

Prototyping is a foundational pillar in modern manufacturing, serving as the critical link between a theoretical design and a market-ready product. For metal stamping parts manufacturers, this phase is not merely about creating a model; it's a comprehensive process of testing, validation, and refinement that ensures the final components are fit for purpose, cost-effective, and of the highest quality. By embracing prototyping, manufacturers can de-risk their projects, foster innovation, and build confidence in their production capabilities long before the first mass-produced part comes off the line.

What is Metal Component Prototyping?

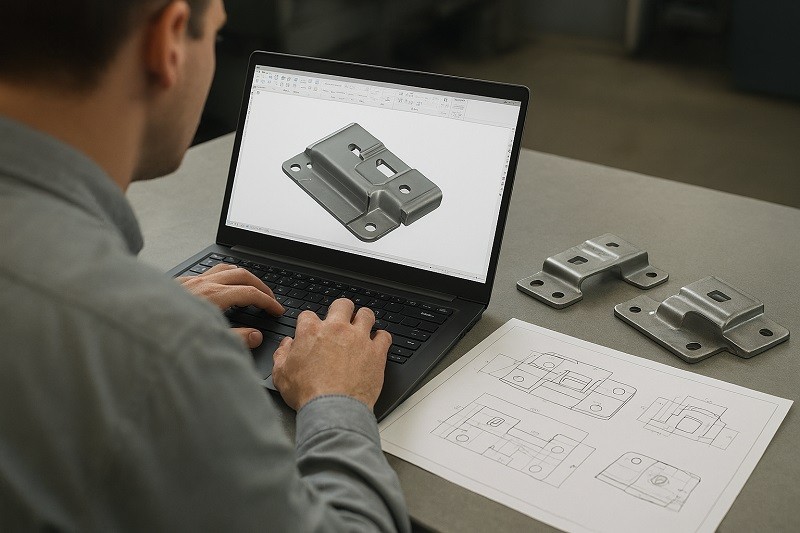

Metal component prototyping is the process of creating an early-model or first-run physical part from a digital design to test and validate its form, fit, and function before committing to mass production. This crucial step allows engineers and designers to hold a tangible version of their concept, bridging the gap between a CAD model on a screen and a real-world component. Prototyping in the context of metal stamping involves using various manufacturing techniques to shape metal into a specified form, which serves as a sample to verify the design.

These initial parts can serve several distinct purposes, often categorized by their fidelity to the final product:

- Visual Prototypes: These models are created to assess the appearance, aesthetics, and ergonomics of a part. They may not possess the functional characteristics or material strength of the final product but are invaluable for stakeholder reviews and market testing.

- Functional Prototypes: These are designed to work like the final product, allowing for rigorous testing of performance, durability, and integration with other components. While they might be made using different methods or materials than in mass production, their primary purpose is to validate that the design performs as intended under real-world conditions.

- Production-Intent Prototypes: As the most refined type, these prototypes are nearly identical to the final part, created using the same materials and manufacturing processes planned for full-scale production. They serve as the final validation step, confirming manufacturability, quality, and process efficiency.

Ultimately, the goal of metal component prototyping is to identify and resolve potential issues early, when changes are less expensive and easier to implement. It provides a physical sample for testing, client feedback, and internal evaluation, ensuring that the final parts meet all required specifications with precision and consistency.

The Iterative Prototype Development Process

The development of a prototype is not a linear path but a cyclical and iterative journey focused on continuous refinement. This methodology, often described as the Design-Build-Test-Learn (DBTL) cycle, ensures that each version of the prototype moves progressively closer to the optimal final design. The process is repeated until the desired level of quality, functionality, and manufacturability is achieved.

The iterative development process generally follows these key steps:

- Design and Conceptualization: The cycle begins with an idea, which is then translated into a detailed 3D CAD model. During this "Design" phase, engineers define critical parameters such as dimensions, tolerances, performance targets, and material requirements.

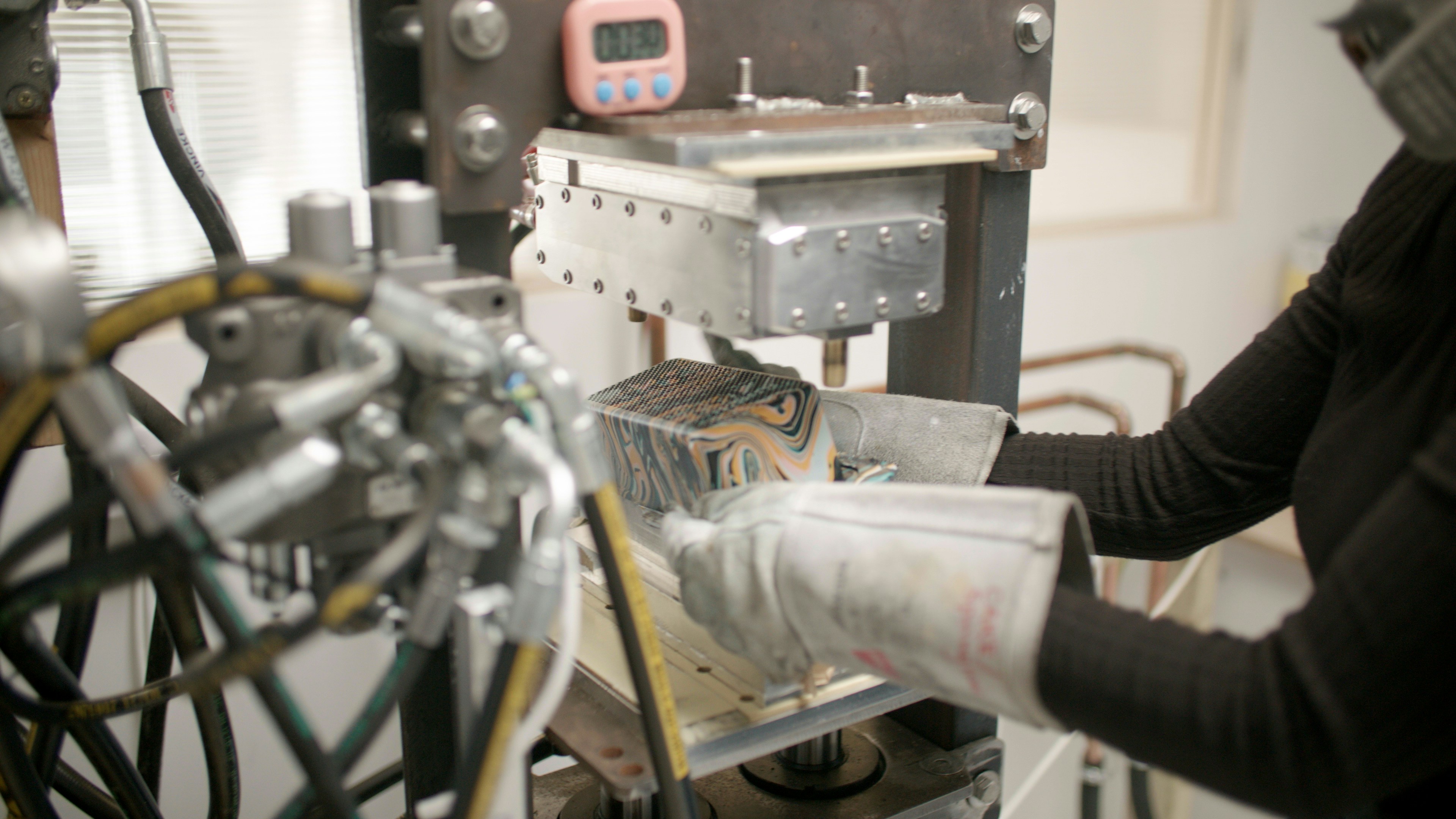

- Build (Fabrication): Once the digital design is ready, a physical prototype is "built" or fabricated. In metal stamping, this may involve creating initial "soft tooling" or using alternative methods like CNC machining or laser cutting to produce the first parts quickly.

- Test and Evaluation: The physical prototype undergoes rigorous "testing" to evaluate its performance against the predefined specifications. This can include dimensional analysis, functional testing under real-world conditions, stress tests, and fitment checks with other components.

- Learn and Refine: In the "Learn" phase, feedback from testing is analyzed to identify design flaws, performance issues, or opportunities for improvement. This new knowledge informs the next iteration, and the cycle begins again with design modifications.

This continuous loop of feedback and improvement is the cornerstone of effective prototyping. It allows manufacturers to make incremental adjustments, experiment with different approaches, and solve problems proactively. By engaging in multiple iterations, companies can enhance collaboration between design and engineering teams, incorporate client feedback effectively, and mitigate risks before they escalate into costly production errors.

The Advantages for Metal Stamping Parts Manufacturers

Engaging in a thorough prototyping process offers substantial, measurable benefits for metal stamping parts manufacturers, reinforcing quality, efficiency, and innovation. The value extends far beyond simply creating a sample part; it is a strategic investment that pays dividends throughout the product lifecycle.

| Advantage | Description |

|---|---|

| Cost Savings and Risk Mitigation | The most significant benefit is the ability to identify and correct design flaws early, before expensive hard tooling is created for mass production. Correcting a mistake at the prototyping stage is exponentially cheaper and faster than making changes mid-production, preventing costly rework, material waste, and tooling modifications. |

| Accelerated Time-to-Market | Rapid prototyping techniques allow manufacturers to quickly produce and test iterations, significantly shortening the development cycle. This speed enables faster design validation and a quicker transition to full-scale manufacturing, helping companies launch their products ahead of the competition. |

| Improved Product Quality and Performance | Prototypes allow for tangible, real-world testing of a component's durability, fit, and functionality. This hands-on evaluation ensures the final product is robust, reliable, and meets or exceeds performance expectations, leading to higher customer satisfaction and a stronger brand reputation. |

| Enhanced Design and Innovation | The flexibility of prototyping encourages experimentation. Designers and engineers can test multiple design variations, explore new materials, and push the boundaries of what's possible without the high stakes of full production. This fosters a culture of innovation and leads to more optimized and competitive products. |

| Better Communication and Collaboration | A physical prototype is a powerful communication tool that bridges the gap between designers, engineers, clients, and investors. It provides a clear, tangible representation of the design intent, facilitating more precise feedback and ensuring all stakeholders are aligned before production begins. |

| Validation of Manufacturability | Prototyping helps confirm that the design is not only functional but also optimized for efficient manufacturing. The process can reveal potential challenges in the stamping process, such as material formability issues or difficulties in achieving tight tolerances, allowing for adjustments that streamline mass production. |

By leveraging these advantages, manufacturers can move forward with the confidence that their designs are validated, their processes are sound, and their final products are poised for success in the market.## Key Stages of Prototype Metal Stamping: A Manufacturer's Perspective

The path from a digital concept to a physical metal component is a structured journey with distinct stages. For metal stamping parts manufacturers, navigating these phases effectively is crucial for success. This process ensures that every aspect of the part—from its design integrity to its material properties—is meticulously planned and executed, setting the foundation for efficient, high-volume production.

Initial Design Consultation and DFM for Metal Stamping Parts Manufacturers

The prototyping journey begins long before any metal is cut. The initial consultation and the application of Design for Manufacturability (DFM) principles are foundational steps that significantly influence the project's outcome.

DFM is a strategic engineering practice that integrates manufacturing considerations directly into the design phase. The goal is to optimize the part's design to make it easier, more efficient, and more cost-effective to produce without compromising functionality or quality. This collaborative process involves a deep dialogue between the customer's designers and the stamping manufacturer's engineers. During this consultation, key questions are addressed to preemptively solve challenges:

- Manufacturing Feasibility: The team assesses whether the proposed design can be realistically and reliably produced using metal stamping technologies.

- Cost-Effectiveness: Small design modifications can lead to significant cost savings. This could involve simplifying complex geometries, adjusting tolerances that are unnecessarily tight, or designing features that reduce tooling wear.

- Material Selection: The discussion will cover the best material for the application, balancing factors like strength, corrosion resistance, weight, and cost.

- Process Optimization: The manufacturer provides insights into the most efficient stamping process (e.g., progressive die, deep draw) and suggests design adjustments to align with the chosen method.

By engaging in DFM early, manufacturers can prevent expensive redesigns, reduce scrap rates, improve production consistency, and accelerate the overall project timeline. This proactive approach ensures that the design is not just innovative but also inherently manufacturable, creating a win-win for both the client and the producer.

Leveraging CAD Software and 3D Simulations in the Prototyping Phase

Once the initial design is refined through DFM principles, it is brought to life in the digital realm using advanced software tools. Computer-Aided Design (CAD) and simulation technologies are indispensable for modern prototyping, allowing for virtual testing and optimization before any physical part is made.

CAD Software is used to create a detailed and precise 3D model of the component. Programs like AutoCAD, SolidWorks, and CATIA have replaced traditional 2D drafting, offering powerful tools for 3D modeling and creating complex assemblies with high accuracy. These digital blueprints are the foundation of the entire manufacturing process, providing the exact geometry needed for simulation, tooling design, and production. Modern CAD software often includes specialized toolsets for sheet metal design, which can automate tasks like creating flat patterns and calculating bend allowances.

3D Simulations, particularly Finite Element Analysis (FEA), are then used to predict how the part will behave during the stamping process and in its final application. FEA works by breaking the 3D model into a mesh of smaller "finite elements" and applying mathematical equations to simulate real-world forces. In metal stamping, this allows engineers to:

- Predict Formability Issues: Simulations can identify potential defects like wrinkling, splitting, or excessive thinning before any tooling is made. This allows for preemptive design changes, such as adjusting bend radii or modifying part geometry.

- Analyze Springback: Metal naturally has a tendency to partially return to its original shape after being formed, a phenomenon known as springback. FEA can predict the amount of springback, enabling engineers to compensate for it in the tool design to ensure dimensional accuracy.

- Optimize Material Usage: By simulating the forming process, manufacturers can determine the optimal blank shape and size, minimizing material scrap.

- Reduce Physical Prototypes: Virtual testing significantly reduces the need for multiple, costly physical prototypes, speeding up the development cycle and lowering costs.

By leveraging these digital tools, manufacturers can engineer a high degree of confidence into the design, ensuring a smoother and more predictable transition to physical prototyping and eventually, mass production.

Tooling, Die Making, and Material Selection for Prototypes

With a digitally validated design, the process moves into the physical realm, starting with material selection and the creation of tooling. These choices are critical, as they directly impact the quality of the prototype and its relevance to the final production part.

Material Selection is a crucial decision that balances performance requirements with manufacturing considerations. The choice of Sheet Metal Fabrication Materials depends on the part's end-use, including factors like required strength, hardness, heat resistance, corrosion resistance, and electrical conductivity. Common materials for metal prototypes include aluminum and various grades of steel, though titanium, copper, and other alloys are used for specific applications. While a prototype is sometimes made from a different, more machinable material to save costs, using the production-intent material is ideal for functional testing to get a true assessment of performance. In such cases, the mechanical and thermal properties must be carefully compared to ensure test results are relevant.

Tooling and Die Making is where the design is translated into the physical tools that will shape the metal. For the prototyping stage, manufacturers often choose between two main types of tooling:

- Soft Tooling: This approach uses molds and dies made from softer, less durable materials like aluminum, silicone, or even 3D-printed composites. Soft tooling is significantly faster and less expensive to create, making it ideal for prototypes and low-volume production runs (typically under 100 parts). It allows for quick design iterations, as modifications to the tools are relatively easy. However, soft tools wear out much faster and may not produce parts with the same precision as hard tooling.

- Hard Tooling: Constructed from robust, high-strength tool steels, hard tooling is designed for durability and high-volume mass production, capable of producing hundreds of thousands or even millions of parts. Creating hard tooling is a more time-consuming and expensive process, with higher upfront costs. It is generally reserved for when the design has been finalized and validated through soft tooling or other prototyping methods.

The choice between soft and hard tooling for prototyping depends on the project's specific needs, including budget, timeline, and required part quantity. Many manufacturers use soft tooling to refine the design and then invest in hard tooling with confidence once the prototype is approved for mass production.## The Benefits of Prototype Review and Rapid Prototyping for Metal Stamping Parts Manufacturers

Once a physical prototype exists, the focus shifts to evaluation and accelerated iteration. This phase is about leveraging the tangible model to its fullest potential—gathering critical feedback, making swift improvements, and using advanced manufacturing techniques to speed up the entire development cycle. For metal stamping parts manufacturers, mastering this stage is key to delivering superior products to market faster.

The Purpose and Value of Prototype Reviews

A prototype review is a structured process of evaluating a preliminary model of a product to validate its design and functionality before full-scale production. This isn't just a casual inspection; it's a critical checkpoint where designers, engineers, clients, and other stakeholders come together to assess the part against its intended requirements. The core purpose is to gather comprehensive feedback that will guide the next iteration or give the green light for production.

The value of this review process is immense:

- Design Validation: A physical prototype allows the team to confirm that the component's design, aesthetics, and ergonomics meet expectations. It's an opportunity to see and feel the product in a way that digital models cannot replicate, providing a more intuitive understanding of its form.

- Functionality and Performance Testing: Prototypes enable rigorous testing in real-world scenarios. This helps verify that the part performs its function correctly and reliably under expected stresses, loads, and environmental conditions.

- Facilitating Clear Communication: A tangible model serves as a powerful communication tool. It eliminates ambiguity and ensures that all stakeholders—from the engineering team to the client—have a shared understanding of the product, which is crucial for gathering precise, actionable feedback.

- Building Stakeholder Confidence: Demonstrating a working prototype is an effective way to secure buy-in from investors or internal decision-makers. It provides tangible proof of the concept's viability and the team's ability to execute the design.

By embedding these collaborative feedback loops into the development process, manufacturers can refine their products based on diverse insights, ensuring the final component is well-aligned with both user needs and business goals.

Identifying and Correcting Flaws Early

One of the most significant financial advantages of prototyping is the ability to detect and correct flaws early in the development cycle. The cost of making a design change multiplies exponentially as a product moves from concept to production. A modification that is simple and inexpensive at the digital design or prototype stage can become prohibitively expensive once hard tooling is made and mass production has begun.

Identifying flaws early provides several key benefits:

- Prevents Costly Rework: Catching issues like an incorrect bend radius, material weakness, or a misaligned feature during the prototype review prevents the need for expensive tooling modifications or scrapping entire batches of production parts.

- Mitigates Production Risks: Prototypes help uncover potential manufacturing challenges before they can disrupt assembly lines. Issues such as part fit problems, assembly difficulties, or material formability limitations can be addressed proactively.

- Avoids Market Failure: Testing a prototype with end-users can reveal critical usability issues or a disconnect with market expectations. This early feedback helps mitigate the risk of launching a product that fails to gain traction with customers.

- Ensures Quality and Reliability: Durability testing on a functional prototype can uncover potential weak points or failure modes that were not predicted by simulations alone. Addressing these issues ensures a more robust and reliable final product.

Ultimately, the small upfront investment in prototyping acts as a powerful insurance policy against much larger costs and delays down the road, ensuring a smoother transition to successful mass production.

Accelerating Innovation with Rapid Prototyping

Rapid prototyping refers to a collection of advanced manufacturing technologies that can create physical parts directly from CAD data with exceptional speed. For metal components, this often involves techniques like 3D printing (specifically Direct Metal Laser Sintering or Selective Laser Melting), CNC machining, and laser cutting. By dramatically reducing the time it takes to create a physical model, rapid prototyping acts as a catalyst for innovation.

Here’s how rapid prototyping accelerates the entire development process:

- Faster Iteration Cycles: Traditional prototyping methods could take weeks or months. With rapid prototyping, a new version of a part can often be produced in hours or days. This allows engineers to test more ideas, refine designs more frequently, and arrive at an optimized solution much faster.

- Reduced Time-to-Market: By compressing the design, build, and test phases, rapid prototyping significantly shortens the overall product development timeline. This enables companies to launch their products sooner, capture market opportunities, and gain a critical competitive advantage.

- Encourages Experimentation: The speed and relatively low cost of rapid prototyping lower the barrier to experimentation. Designers and engineers are more willing to explore bold, innovative concepts when they can quickly create a physical model to test their ideas without committing to expensive tooling.

- Improves Design Flexibility: Changes can be made quickly and efficiently. If a test reveals a flaw or an opportunity for improvement, the CAD model can be adjusted, and a new prototype can be fabricated almost immediately, enabling a more agile and responsive design process.

By integrating rapid prototyping into their workflow, metal stamping parts manufacturers can foster a culture of continuous improvement, push the boundaries of design, and deliver cutting-edge solutions to their clients with unparalleled speed and efficiency.## Navigating Challenges and Ensuring Quality through Prototyping in Metal Stamping Parts Manufacturing

The journey through prototyping is not just about design validation; it's also about proactively identifying and solving manufacturing challenges. For metal stamping parts manufacturers, this phase is a critical opportunity to ensure the final product can be produced consistently and at the highest quality. By addressing material behaviors, implementing rigorous quality control, and optimizing process parameters, manufacturers can transition from prototype to production with confidence.

Addressing Material Challenges in Precision Metal Stamping

The material selected for a part is fundamental to its success, but every material presents a unique set of challenges during the stamping process. Prototyping provides a practical arena to understand and mitigate these issues before they can impact large-scale production.

Key material properties and their associated challenges include:

- Ductility and Formability: This refers to a metal's ability to be stretched, bent, or drawn into a shape without cracking or fracturing. Materials with low ductility can be prone to cracking, especially when forming complex geometries or tight bend radii. Prototyping allows manufacturers to test the limits of a material's formability and adjust the design—for example, by increasing a bend radius—to prevent such defects.

- Hardness and Strength: Harder, stronger materials like stainless steel or high-carbon steel are durable but place significant stress on stamping dies, leading to faster tool wear. During the prototype phase, manufacturers can evaluate tool performance and plan for appropriate maintenance schedules or select more robust tool materials for mass production.

- Springback: After being stamped, metal has an elastic tendency to return slightly to its original shape. This "springback" can cause dimensional inaccuracies in the final part. Prototyping helps quantify the amount of springback for a specific material and design, allowing engineers to compensate by overbending the part in the tooling design to achieve the correct final angle.

- Wrinkling and Thinning: In deep drawing processes, compressive stresses can cause the material to wrinkle, while excessive tensile stresses can lead to localized thinning or splits. Simulation and physical prototyping help identify these risks, allowing for adjustments to process parameters like blank holder force or lubrication to ensure uniform material flow.

By confronting these material challenges during prototyping, manufacturers can refine part designs and processes to ensure they are robust and reliable for high-volume production.

The Importance of Quality Control and Inspection in Prototyping

Quality control during the prototyping phase is not just about inspecting the final sample; it's a continuous process that ensures every aspect of the part aligns with its specifications. Rigorous inspection at this stage is crucial for validating the design and the manufacturing process itself.

Several inspection methods are employed to ensure prototype quality:

- Visual and Tactile Inspection: The first step often involves a simple visual check for macroscopic defects like burrs, scratches, or surface imperfections. Experienced inspectors may also perform a touching inspection, using their hands to feel for subtle unevenness or flaws on the part's surface.

- Dimensional Inspection: This is the cornerstone of prototype QC. Precise measurements are taken to verify that all dimensions, tolerances, and geometric features match the CAD model and engineering drawings.

- Coordinate Measuring Machines (CMM): For parts requiring high precision, CMMs are invaluable inspection tools. A CMM uses a highly sensitive probe to touch various points on the part's surface, generating a precise 3D map of its geometry. This data is then compared directly to the original CAD model to identify any deviations with extreme accuracy.

- 3D Laser Scanning: As an alternative to CMMs, 3D laser scanners can quickly capture full-field data of a part's surface, creating a detailed point cloud. This method is efficient for inspecting complex shapes and identifying issues like springback or surface deviations.

By implementing a robust quality control protocol during prototyping, manufacturers can ensure that the part is dimensionally accurate, free of defects, and fully conforms to the design intent, paving the way for consistent quality in mass production.

Optimizing Process Settings and Material Consistency

Beyond validating the part itself, prototyping is a critical opportunity to fine-tune the manufacturing process for optimal efficiency and repeatability. The lessons learned during prototype production directly inform the settings and controls that will be used in high-volume manufacturing.

Key areas of process optimization include:

- Refining Stamping Parameters: Prototyping allows manufacturers to experiment with and dial in crucial process parameters such as press speed, tonnage (force), and blank holder force. Identifying the optimal settings for these variables helps prevent defects, reduce tool wear, and ensure a stable and efficient production run.

- Ensuring Material Consistency: Variations in raw material—such as slight differences in thickness, hardness, or chemical composition between coils of metal—can lead to inconsistencies in stamped parts. The prototyping phase helps establish a baseline for acceptable material properties and allows manufacturers to develop quality control checks for incoming raw materials to ensure uniformity. This consistency is the foundation of achieving high repeatability in custom metal stamping.

- Lubrication Strategy: The type and application of lubricant can significantly impact material flow, friction, and tool life. Prototyping provides a chance to test different lubrication strategies to find the one that best prevents defects and maximizes efficiency.

- From Prototype to Production: The hands-on experience of making a prototype gives manufacturers a deep understanding of how a part will behave in production. This knowledge is invaluable for anticipating potential bottlenecks, optimizing workflows, and ensuring a seamless transition from low-volume prototyping to high-volume manufacturing.

By using the prototyping phase to validate not just the product but also the process, manufacturers can ensure that when the time comes for mass production, they are ready to produce high-quality parts with exceptional consistency and efficiency.## Partnering with Expert Metal Stamping Parts Manufacturers for Prototyping Success

The success of a prototyping project—and the final product—often hinges on the capabilities of the manufacturing partner. Choosing a metal stamper with a deep well of experience, the right equipment, and a flexible, customer-centric approach can make the difference between a smooth-running project and one plagued by delays and cost overruns. A true partner does more than just fabricate parts; they provide invaluable guidance and expertise at every stage, from initial design to final delivery.

The Value of Experience and Advanced Equipment

When it comes to precision metal stamping, there is no substitute for experience. A seasoned manufacturing partner brings a wealth of knowledge gained over decades and thousands of projects. This expertise is crucial for navigating the complexities of stamping, especially for components used in demanding industries like automotive, aerospace, medical, and electronics.

An experienced team can:

- Provide Invaluable Design for Manufacturability (DFM) Insights: They can assess a design and immediately spot potential manufacturing challenges, suggesting modifications that will improve part quality, reduce costs, and streamline production.

- Troubleshoot Complex Issues: Experienced engineers understand the nuances of how different materials behave under pressure and can anticipate and solve problems like springback, cracking, or wrinkling before they occur.

- Navigate Industry-Specific Standards: Partners with a history of serving specific sectors, such as medical or aerospace, are well-versed in the stringent regulatory and quality requirements of those industries.

Complementing this experience is the need for advanced equipment. The precision and efficiency of modern metal stamping are driven by technology. A capable partner will have invested in a wide range of state-of-the-art machinery, including:

- High-Tonnage Mechanical and Servo Presses: A variety of presses (from 25 to over 400 tons) allows a manufacturer to handle parts of different sizes and complexities. Servo presses, in particular, offer precise control over the stamping process, which is ideal for forming complex geometries.

- In-House Tool and Die Making: A manufacturer with an in-house tool room can design, build, and maintain its own stamping dies. This is a significant advantage, as it shortens lead times, reduces costs, and allows for rapid tool modifications during the prototyping phase.

- Advanced Inspection and Metrology Equipment: Tools like Coordinate Measuring Machines (CMMs), 3D laser scanners, and vision systems are essential for ensuring that prototypes and production parts meet tight tolerances and quality standards.

Cost Efficiency and Timely Delivery in Prototyping Projects

Speed and cost are two of the most critical factors in any product development cycle. An expert prototyping partner understands this pressure and structures their processes to deliver both efficiency and value.

Cost efficiency in prototyping is not simply about finding the lowest price. A strategic partner helps reduce the total cost of the project in several ways:

- Low-Cost Tooling Solutions: For prototypes and short runs, experienced manufacturers can utilize more economical "soft tooling" or other cost-effective fabrication methods like CNC machining and laser cutting to produce parts without the high upfront investment of production tooling.

- Reduced Material Waste: Through careful DFM and process optimization, a skilled partner minimizes scrap, which directly translates to lower material costs.

- Avoiding Expensive Rework: The most significant cost savings come from getting the design right early. By identifying and fixing flaws during the prototyping stage, manufacturers prevent the enormous expenses associated with making changes during mass production.

Timely delivery is equally critical to stay on schedule and achieve a faster time-to-market. Top prototyping partners prioritize speed and reliability through:

- Rapid Prototyping Capabilities: Leveraging technologies that can produce parts in as little as a few days allows for quicker design validation and iteration.

- On-Demand Manufacturing: A flexible partner can respond quickly to urgent needs, keeping a project on track even when unexpected issues arise or design changes are required.

- Transparent Communication: Reliable manufacturers provide realistic delivery timelines and maintain open communication, ensuring there are no surprises and that the project stays on schedule.

Customization and Flexibility for Diverse Applications

No two projects are alike, and a one-size-fits-all approach is rarely effective in precision manufacturing. The ability to provide customized solutions and remain flexible is a hallmark of a top-tier prototyping partner. This adaptability is essential for serving a wide array of industries, each with its own unique challenges and requirements.

Customization means tailoring every aspect of the prototyping process to the specific needs of the project. This includes:

- Material Expertise: Helping the customer select the perfect material from a wide range of options—including steel, aluminum, brass, copper, and specialty alloys—to meet the specific performance and environmental demands of the application.

- Custom Tooling: Designing and building prototype tooling that is optimized for the part's specific geometry and required quantity, ensuring both quality and cost-effectiveness.

- Secondary Operations: Offering a full suite of in-house services such as assembly, welding, finishing, and plating allows a partner to deliver a complete, turn-key component.

Flexibility is the ability to adapt to changing project needs and offer a variety of solutions. A flexible manufacturing partner can:

- Handle a Range of Volumes: They can efficiently produce everything from a single prototype to low-volume initial runs and then seamlessly scale to mass production.

- Offer Multiple Prototyping Methods: An ideal partner has a variety of technologies at their disposal—from stamping and forming to CNC machining and 3D printing—and can recommend the best process for the specific part and development stage.

- Serve Diverse Industries: Experience across multiple sectors, such as automotive, medical, aerospace, electronics, and consumer goods, demonstrates a manufacturer's ability to adapt to different standards, materials, and complexities.

By providing this level of customization and flexibility, an expert manufacturer acts as a true strategic partner, helping innovators turn their unique design concepts into successful, market-ready products.

Key Takeaways

Prototyping is an indispensable strategic phase in precision metal stamping, offering a powerful methodology to refine designs, validate performance, and ensure manufacturability before committing to the high costs of mass production. It bridges the critical gap between a digital concept and a market-ready product, providing a tangible pathway to innovation and quality.

Here are the essential takeaways on the role of prototyping for metal stamping parts manufacturers:

- Foundation in Design and Validation: Prototyping starts with a robust design consultation and the application of Design for Manufacturability (DFM) principles. This collaborative effort aligns design intent with production realities, leveraging CAD modeling and FEA simulations to virtually test and optimize parts, preventing costly issues down the line.

- Iterative Refinement is Key: The process is cyclical, following a Design-Build-Test-Learn loop. Each iteration brings the component closer to perfection by gathering feedback, identifying flaws, and making informed adjustments. This ensures the final product is not only functional but also optimized for efficiency and performance.

- Early Flaw Detection Saves Time and Money: One of the greatest values of prototyping is its ability to uncover design and manufacturing flaws at the earliest, least expensive stage. Addressing issues with material formability, springback, or dimensional inaccuracies before creating hard tooling prevents catastrophic budget overruns and production delays.

- Accelerates Innovation and Speed-to-Market: Rapid prototyping technologies, such as 3D printing and quick-turn CNC machining, dramatically shorten development cycles. This speed empowers manufacturers to experiment with more innovative designs, iterate faster, and ultimately bring superior products to market ahead of the competition.

- Ensures Quality and Consistency: Prototyping is a crucial platform for establishing rigorous quality control from the very beginning. By using advanced inspection methods like CMM and 3D scanning on prototypes, manufacturers can validate part accuracy and optimize process parameters. This ensures a seamless and predictable transition to high-volume production where consistency is paramount.

- The Right Partner is a Strategic Advantage: Partnering with an experienced metal stamping manufacturer equipped with advanced technology, in-house tooling capabilities, and a flexible, customer-centric approach is critical. Such a partner offers not just fabrication services but also invaluable expertise in material selection, cost efficiency, and timely delivery, ensuring the success of the entire project.

Embracing a comprehensive prototyping strategy is a strategic imperative for any manufacturer looking to lead in today's competitive landscape. It mitigates risk, enhances quality, and fosters the innovation needed to deliver products that meet and exceed market expectations.

Frequently Asked Questions (FAQ)

What is the primary difference between a prototype and a final production part in metal stamping?

The primary difference lies in their purpose, manufacturing method, and cost. A prototype is an early-stage model created to test a design's form, fit, and function, often made in small quantities using flexible and lower-cost methods like soft tooling or CNC machining. Its cost per unit is high, but the total project cost is low. A final production part, on the other hand, is manufactured in high volumes using durable, expensive "hard" tooling designed for mass production. The goal of production is to create identical parts at a low per-unit cost with maximum efficiency and repeatability.

How much does metal stamping prototyping typically cost?

The cost of a metal stamping prototype can vary significantly based on several factors:

- Part Complexity: Intricate geometries and tight tolerances require more advanced tooling and processing, increasing costs.

- Material: The price of the selected metal (e.g., standard steel vs. a specialty alloy like titanium) will directly impact the cost.

- Tooling Type: Using "soft tooling" (e.g., aluminum dies) is much cheaper for small batches than creating durable "hard tooling" (steel dies) intended for mass production.

- Quantity: The per-piece price decreases as the quantity increases, but the initial tooling and setup costs are fixed.

- Finishing Requirements: Secondary operations like plating, heat treating, or painting will add to the overall cost. It is always best to consult with a manufacturing partner for a detailed quote based on your specific design.

How long does the metal stamping prototyping process take?

The timeline for metal stamping prototyping can range from a few days to several weeks, depending on the project's complexity. For simpler parts using readily available materials, a rapid prototype can sometimes be produced in as little as 48 hours to a week using methods like laser cutting or CNC machining. More complex prototypes that require custom soft tooling may take two to four weeks. The overall lead time is influenced by factors such as design finalization, tool creation, material availability, and the number of iterations required.

What is the difference between soft tooling and hard tooling?

Soft tooling is made from less durable materials like aluminum or epoxy and is intended for prototyping and low-volume production. It is faster and cheaper to create but wears out quickly, typically lasting for only a small number of parts (e.g., up to 100). It’s ideal for testing designs and making frequent adjustments.

Hard tooling is constructed from high-strength tool steel and is designed for high-volume mass production, capable of producing hundreds of thousands or even millions of identical parts. It has a much higher upfront cost and a longer lead time to manufacture but offers superior precision, durability, and a lower per-part cost over a long production run.

Why can't I just use 3D printing for all my metal prototypes?

While 3D printing (Direct Metal Laser Sintering or DMLS) is an excellent technology for creating complex geometries quickly, it has limitations. 3D-printed metal parts may not have the same mechanical properties, strength, or surface finish as a part formed through stamping. Stamping work-hardens the metal, which can be a critical performance characteristic that 3D printing doesn't replicate. For validating the true performance and manufacturability of a part that will ultimately be stamped, creating a prototype using a forming process is often necessary.

Conclusion

From the initial concept scribbled on a napkin to the final high-volume production run, prototyping stands as a cornerstone for success in precision metal stamping. It is far more than an optional pre-production check; it is an integrated, strategic process that empowers manufacturers to innovate, optimize, and deliver with unparalleled confidence. By transforming digital designs into tangible parts, prototyping enables rigorous validation of form, fit, and function, ensuring that any potential flaws are identified and corrected when the cost of change is at its absolute minimum.

Embracing robust prototyping strategies—from early-stage Design for Manufacturability (DFM) and advanced simulations to rapid iterations and meticulous quality control—ensures that we, as expert Metal Stamping for Manufacturers, can consistently meet the evolving demands of our clients. This proactive approach not only mitigates risk and shortens time-to-market but also fosters a culture of innovation, pushing the boundaries of what is possible. Ultimately, it allows us to offer not just components, but complete, reliable solutions that drive progress and build lasting partnerships.

We encourage you to share this article with your network and engage in the conversation. How has prototyping transformed your manufacturing process? What challenges have you overcome? Your insights help us all move the industry forward.