The Die Casting Process: A Step-by-Step Manufacturing Guide

I'm going to guide you through the fascinating world of die casting, a manufacturing method I often use to produce precise, durable, and lightweight metal parts. You'll learn how this process allows for high-volume production of complex shapes with excellent surface finishes. Die casting is a widely used and cost-effective manufacturing process. I'll explain how it works and what makes it such an efficient way to create metal components for almost every industry, from tiny electronic parts to large automotive components.

Key Takeaways

- Process Overview: The die casting process involves six main steps: die preparation (cleaning and lubrication), metal melting, high-pressure injection of molten metal into the die, cooling and solidification, ejection of the part, and trimming of excess material. This cycle is highly automated and can be repeated rapidly.

- Types of Die Casting: The two primary methods are hot-chamber and cold-chamber die casting. Hot-chamber is used for low-melting-point alloys like zinc and magnesium, where the injection mechanism is immersed in the molten metal. Cold-chamber is necessary for high-melting-point alloys like aluminum, where the molten metal is ladled into the injection system for each cycle to prevent damage to the machine.

- Specialized Techniques: For advanced applications, specialized methods like vacuum, squeeze, and semi-solid die casting are used. Vacuum casting reduces porosity, squeeze casting produces dense, heat-treatable parts, and semi-solid casting offers high precision with minimal porosity. Low-pressure die casting is another variant, ideal for creating symmetrical aluminum parts.

- Quality is Paramount: Achieving high-quality die castings starts with excellent design (Design for Manufacturability), selecting premium materials like high-purity aluminum ingots and specific alloys (e.g., A380), and using simulation software to predict and prevent defects.

- Post-Casting and Inspection: After casting, parts undergo treatments like sandblasting and surface finishing to improve aesthetics and performance. Rigorous quality control, including visual and dimensional checks, is essential to ensure every part meets specifications before storage and transport.

- Key Advantages: Die casting is renowned for its ability to produce parts with high precision, intricate details, and excellent surface finishes. Its high production speed makes it extremely cost-effective for large volumes. The process is also versatile, compatible with a wide range of non-ferrous alloys.

- Wide Range of Applications: Die casting is a cornerstone of the automotive industry, used for engine blocks, transmission housings, and structural components for electric vehicles. It's also prevalent in aerospace, electronics (for housings and heat sinks), and countless everyday consumer products.

Understanding the Die Casting Process: A Step-by-Step Overview

Die casting is a highly efficient manufacturing process used to produce metal parts by forcing molten metal into a reusable mold, known as a die, under high pressure. This method is renowned for creating components with high precision, complex shapes, and a smooth surface finish, making it suitable for mass production. The entire operation can be broken down into a series of well-defined steps, ensuring consistency and quality from one part to the next. The foundational stages of traditional high-pressure die casting include preparing the die, melting and injecting the metal, allowing it to cool and solidify, and finally ejecting and finishing the part. This cycle allows for the rapid creation of parts from non-ferrous metals like aluminum, zinc, and magnesium.

My Initial Steps: Mold Preparation and Metal Melting for Die Casting

Before any metal is cast, two critical preliminary stages must be perfectly executed: preparing the mold and melting the metal alloy. These foundational steps are crucial for ensuring the final part's quality, dimensional accuracy, and structural integrity. A properly prepared die guarantees a clean release and smooth surface finish, while precise metal melting ensures the molten alloy has the correct properties for injection.

Preparing the Die: Cleaning and Lubrication

The die, typically made from high-quality, heat-resistant steel, must be meticulously prepared before each injection cycle. This preparation phase is fundamental to the entire process.

First, the die halves are thoroughly cleaned to remove any residue, debris, or contaminants from the previous cycle. This can be done through several methods, including manual cleaning with brushes and solvents, ultrasonic cleaning for hard-to-reach areas, or advanced techniques like laser cleaning. A clean mold surface is essential for producing a defect-free part with a high-quality surface finish.

Next, a lubricant or release agent is carefully applied to the inner surfaces of the mold cavity. This serves three primary purposes:

- Facilitating Ejection: The lubricant forms a barrier between the molten metal and the die surface, preventing the solidified part from sticking and ensuring a smooth, damage-free release.

- Controlling Temperature: The lubricant helps to regulate the temperature of the die, preventing thermal shock when the extremely hot molten metal is injected. This thermal management is crucial for extending the life of the die.

- Improving Metal Flow: A properly lubricated surface helps the molten metal flow smoothly and evenly into all the intricate details of the cavity.

After lubrication, the two halves of the die are closed and securely clamped together by the powerful hydraulic system of the die casting machine, preparing it for the injection of molten metal.

Melting the Metals: My Choice of Aluminum and Other Alloys

Concurrently with die preparation, the chosen metal alloy is melted in a furnace. The selection of the alloy is critical and depends entirely on the part's intended application, required strength, corrosion resistance, and thermal properties. Aluminum is one of the most popular materials in die casting due to its light weight, high-temperature resistance, and excellent strength.

The process typically begins with high-quality metal ingots, which are loaded into a melting furnace. This can be a separate furnace in the cold chamber process or a furnace built into the machine in the hot chamber process. The furnace heats the metal to a precise temperature, well above its melting point, to ensure it is completely molten and has the right fluidity for injection. For aluminum, this temperature is typically above 660°C (1220°F). Accurate temperature control is crucial; overheating can degrade the alloy's properties, while underheating can lead to a sluggish flow and incomplete filling of the die cavity.

Common alloys I frequently work with include:

- Aluminum Alloys: A380 is a versatile, all-purpose alloy offering a great combination of casting and mechanical properties. Other variants like A360 offer superior corrosion resistance, while ADC12 is known for its excellent die-filling capabilities.

- Zinc Alloys: Due to their low melting point, zinc alloys like Zamak 3 are very easy to cast, offer excellent ductility, and allow for a very long die life.

- Magnesium Alloys: AZ91D is favored for applications where light weight is the top priority, as it is the lightest of all structural alloys.

Once the metal reaches the desired molten state and purity, it is ready for the next and most dynamic stage of the process: injection.

| Alloy Group | Common Examples | Key Characteristics |

|---|---|---|

| Aluminum | A380, ADC12, A360 | Lightweight, high-temperature resistance, good strength-to-weight ratio. |

| Zinc | Zamak 3, Zamak 5 | Low melting point, high ductility, excellent for thin walls and fine details. |

| Magnesium | AZ91D | Extremely lightweight, excellent machinability, high strength-to-weight ratio. |

The Core of Die Casting: Injecting and Solidifying the Molten Metal

This phase is the heart of the die casting cycle, where the liquid metal takes the shape of the final part. It consists of two seamlessly integrated actions: the high-speed injection of the molten alloy and its subsequent rapid cooling and solidification within the die. The precision and control exercised during these moments are what define the quality and integrity of the finished component.

High-Pressure Injection: Filling the Die Cavity Precisely

Once the die is clamped shut, the molten metal is injected into the die cavity at an extremely high speed and pressure. This is arguably the most critical phase, as the manner of injection directly impacts the final part's density, finish, and structural integrity. A hydraulic-powered piston forces a pre-measured amount of molten metal—known as a "shot"—into the die. Injection pressures are immense, often ranging from 1,500 to over 25,000 pounds per square inch (PSI).

This intense pressure ensures the molten metal fills every corner, crevice, and detail of the mold in milliseconds, before any part of it has a chance to solidify prematurely. High-pressure injection is crucial for producing parts with thin walls and complex geometries, which would be impossible to fill using gravity alone. This rapid and forceful filling minimizes defects like non-fills or cold shuts (where two fronts of cooling metal fail to fuse properly) and helps achieve a part with a good surface finish and dimensional accuracy. In modern die casting, simulation software is often used to model and analyze the die cavity filling process, helping engineers optimize gate locations and flow paths to prevent turbulence and air entrapment.

Cooling and Solidification: Ensuring Structural Integrity in Die Casting

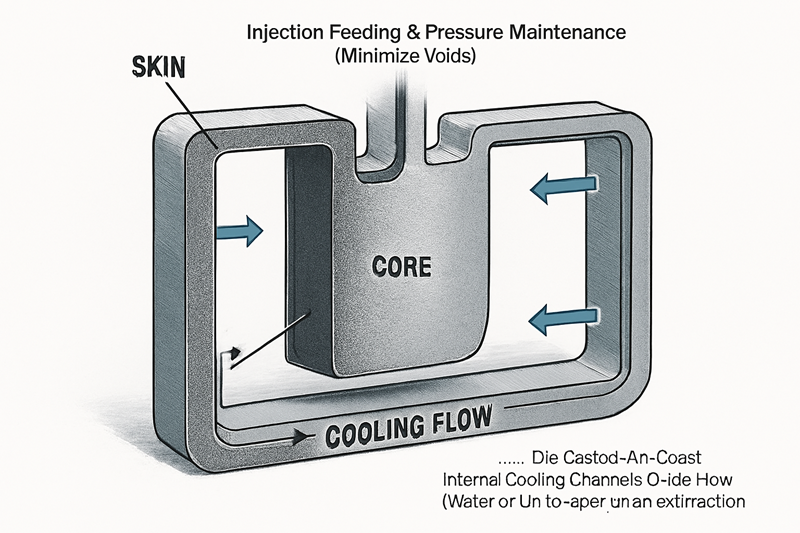

As soon as the molten metal fills the die cavity, the cooling and solidification process begins. This stage is critically important for the final part's structural integrity and mechanical properties. The die is typically engineered with internal cooling channels through which water or oil circulates, allowing for precise and rapid heat extraction.

The cooling rate is a carefully controlled parameter.

- Rapid Cooling: Fast solidification creates a fine-grained microstructure on the surface of the casting, often called the "skin effect." This skin is dense and strong, contributing significantly to the part's overall durability.

- Controlled Cooling: The overall cooling must be uniform to prevent defects. If one section of the part cools much faster than another, it can lead to internal stresses, warping, or shrinkage porosity (voids created as the metal shrinks during solidification).

The solidification process happens very quickly, often within seconds to minutes, depending on the alloy, wall thickness, and complexity of the part. The pressure from the injection phase is maintained during the initial part of solidification to help feed more molten metal into the cavity, compensating for shrinkage and minimizing porosity. Proper solidification is the key to producing a strong, dense, and dimensionally stable component that can withstand its intended operational stresses.

Finishing the Die Casting Cycle: Ejection and Trimming

The final stage of the die casting cycle involves removing the newly formed part from the die and preparing it for any subsequent finishing operations. This two-part process—ejection and trimming—is essential for completing the transformation from raw metal to a near-net-shape component.

Ejecting the Cast Part: Gentle Removal to Prevent Damage

Once the casting has fully solidified and cooled to a manageable temperature, the die halves are opened. At this point, a mechanism within the die casting machine is activated to push the part out of the mold. This is accomplished by a set of ejector pins. These pins are carefully placed within the die design to push against specific, non-cosmetic, and structurally robust areas of the part.

The ejection force must be carefully calibrated. If it's too weak, the part won't release; if it's too strong or unevenly applied, it can cause deformation, stress marks, or even cracks in the casting. Proper mold design, including adequate draft angles (slight tapering of the part walls), and the use of release agents are both crucial for ensuring a smooth and gentle ejection. The ejector pins push the entire "shot"—which includes the finished part(s), runners, and flash—out of the die, making it ready for the final step.

Trimming the Excess: Refining the Die Cast Component

The ejected shot is not yet a finished part. It consists of the actual component connected to the runners (channels that guided the metal), gates (entry points into the part), and often some thin excess material called flash. Flash forms when a small amount of molten metal seeps into the parting line between the die halves. All this excess material must be removed.

This is done through a trimming process. Common trimming methods include:

- Trim Press: This is the most common method for high-volume production. The entire shot is placed into a trimming die, and a hydraulic press shears off the runners, gates, and flash in a single, swift motion.

- Manual Trimming: For smaller production runs or highly complex parts, workers may manually remove excess material using tools like files, grinders, or saws. This is more labor-intensive but allows for greater precision on delicate features.

- Cryogenic Deflashing: In this specialized method, parts are cooled to very low temperatures with liquid nitrogen, making the thin flash brittle and easy to remove through tumbling or light abrasion.

After trimming, the part is in its near-net shape. The trimmed excess material, such as runners and flash, is collected and remelted, making die casting a highly sustainable process with minimal material waste.

Exploring Different Types of Die Casting Methods I Utilize

While the fundamental principle of die casting remains the same—injecting molten metal into a die—several distinct methods have been developed to suit different metals, part complexities, and production requirements. The primary distinction lies between hot-chamber and cold-chamber die casting, but I also utilize more specialized techniques for applications demanding specific properties. Properly executing these advanced methods requires specialized expertise, which is a hallmark of high-quality die casting services.

Hot-Chamber Die Casting: My Go-To for Lower Melting Point Metals

Hot-chamber die casting, also known as gooseneck casting, is characterized by its speed and efficiency. In this method, the injection mechanism is submerged in a bath of molten metal held in a furnace that is integral to the casting machine.

Here’s a breakdown of the process:

- Chamber Filling: At the start of a cycle, a plunger rises, allowing a port to open. Molten metal from the furnace naturally fills the "gooseneck," which is the chamber for the injection system.

- Injection: The plunger then pushes down, forcing the molten metal through a nozzle and into the die cavity under pressure.

- Solidification and Ejection: The metal cools and solidifies, the die opens, and the part is ejected.

Advantages:

- Speed: Because the furnace is built into the machine, the time needed to transfer metal is eliminated, allowing for very rapid cycle times—often up to 15 cycles per minute.

- Efficiency: The direct integration of the melting and injection systems reduces energy loss and metal oxidation.

- Automation: The process is easily automated, leading to consistent production and lower labor costs.

Limitations and Suitable Materials: This method is only suitable for alloys with low melting points that are not corrosive to the submerged steel injection components. If high-melting-point metals like aluminum were used, they would quickly damage the gooseneck and plunger. Therefore, I use hot-chamber die casting primarily for:

- Zinc alloys: (e.g., Zamak 3, Zamak 5)

- Lead- and tin-based alloys

- Some magnesium alloys

Due to its high speed and efficiency, hot-chamber die casting is ideal for producing large volumes of small to medium-sized parts with intricate details.

Cold-Chamber Die Casting: My Approach for High Melting Point Alloys Like Aluminum

When working with alloys that have high melting points, such as aluminum, brass, or copper, the hot-chamber process is not viable. The constant exposure to these high-temperature molten metals would destroy the machine's injection system. This is where the cold-chamber method comes in. It is my preferred approach for producing durable, lightweight aluminum components.

The defining feature of the cold-chamber process is the separation of the melting furnace from the die casting machine.

The key steps are:

- Melting: The metal is melted in a completely separate furnace.

- Transfer (Ladling): For each casting cycle, a precise amount of molten metal is transferred from the furnace to the machine's injection chamber (the "cold chamber" or shot sleeve). This is typically done with an automated ladle.

- Injection: A hydraulic or mechanical plunger, which has not been in prolonged contact with the molten metal, then forces the shot into the die cavity at high pressure.

Advantages:

- Material Versatility: This process is suitable for high-melting-point alloys like aluminum, magnesium, and copper, which offer superior strength and durability.

- Reduced Contamination: Because the injection components are not constantly submerged in molten metal, there is less risk of metal contamination or alloy degradation.

- Larger Parts: Cold-chamber machines are typically more robust and can be used to produce larger and more structurally demanding parts compared to hot-chamber machines.

- High-Integrity Castings: The process allows for very high injection pressures, resulting in dense parts with excellent mechanical properties.

Limitations:

- Slower Cycle Times: The need to ladle metal for each shot makes the cycle times slower than in the hot-chamber process.

- Increased Oxidation: The transfer of molten metal from the furnace to the machine can expose it to the atmosphere, increasing the potential for oxidation if not properly managed.

For applications in the automotive, aerospace, and electronics industries where the combination of light weight and high strength is critical, cold-chamber die casting of aluminum alloys is the industry standard.

Specialized Die Casting Techniques: Vacuum, Squeeze, and Semi-Solid Casting

Beyond the standard hot- and cold-chamber methods, certain applications require even more advanced techniques to achieve superior part quality. I employ these specialized processes when the component demands properties like exceptional strength, near-zero porosity, or extreme density. These methods represent the cutting edge of die casting technology and require a deep understanding of material science and process control.

Vacuum Die Casting: Reducing Porosity for Enhanced Strength

In conventional die casting, the high-speed injection of molten metal can trap air within the die cavity. This trapped air leads to a defect known as gas porosity—small voids or bubbles within the solidified part that can compromise its structural integrity and surface finish. For components that must be leak-proof, weldable, or possess maximum strength, porosity is a significant concern.

This is where Vacuum-Assisted High-Pressure Die Casting (VAHPDC) comes in. In this process, a vacuum system is connected to the die. Just before the molten metal is injected, the vacuum pump evacuates the air and other gases from the die cavity.

Benefits:

- Reduced Porosity: By removing the air from the cavity before injection, gas porosity is virtually eliminated. This results in a denser, stronger part.

- Improved Mechanical Properties: Castings produced with this method show significant improvements in tensile strength and elongation. They are also heat-treatable and weldable, which is often not possible with conventional die castings due to trapped gases expanding and causing blisters or cracks.

- Enhanced Surface Finish: The absence of trapped air allows for a smoother, more consistent surface, which is ideal for parts requiring high-quality cosmetic finishes or plating.

- Casting of Thinner Walls: The vacuum helps draw the molten metal into very thin and complex sections of the mold that might not fill completely under normal conditions.

This technique is my method of choice for critical applications in the automotive and marine industries, such as structural components, engine parts, and housings that need to be completely free of leaks and defects.

Squeeze Casting: Achieving High Density and Microstructural Refinement

Squeeze casting, which is also known as liquid-metal forging, is a hybrid manufacturing process that merges the benefits of die casting and forging. It's designed to create parts that are exceptionally dense, strong, and entirely free of porosity. I turn to this method when a component's structural integrity is absolutely non-negotiable.

The process involves two main variations:

- Direct Squeeze Casting: A precise volume of molten metal is poured into the bottom half of a preheated die. The top half of the die then closes, applying immense and sustained pressure (often over 15,000 PSI) as the metal solidifies. This intense pressure closes any voids and ensures intimate contact between the metal and the die surface, promoting rapid and uniform cooling.

- Indirect Squeeze Casting: This is more similar to conventional die casting, but after the die cavity is filled, an additional, extremely high pressure is applied to "squeeze" the solidifying metal.

Key Advantages:

- Near-Zero Porosity: The high pressure applied during solidification effectively eliminates both gas and shrinkage porosity, resulting in a fully dense part.

- Superior Mechanical Properties: Squeeze-cast parts exhibit mechanical properties that approach those of forged components, including high strength, ductility, and fatigue resistance.

- Fine-Grain Microstructure: The rapid heat transfer facilitated by the high pressure results in a very fine and uniform grain structure, which further enhances the material's strength.

- Heat Treatable: The absence of porosity makes these parts perfectly suitable for heat treatment (like T5 or T6 tempers), which can further boost their mechanical properties.

- Near-Net-Shape: The process can produce complex shapes with high precision, significantly reducing the need for secondary machining.

Due to its ability to produce highly reliable, high-integrity parts, squeeze casting is my preferred method for critical automotive components like chassis frames, suspension parts, and aluminum front steering knuckles.

Semi-Solid Die Casting: Precision and Minimal Porosity with Thixocasting

Semi-Solid Die Casting (SSM), often involving a technique called thixocasting, is an advanced process that bridges the gap between casting and forging. Instead of injecting fully liquid metal, this method uses a metal alloy that has been heated to a state between its solidus and liquidus temperatures, resulting in a slurry-like consistency that is part solid and part liquid (typically 30-65% solid).

This slurry has a unique property called thixotropy: it is thick and viscous when at rest but flows like a fluid when agitated or put under shear stress. The thixocasting process typically involves these steps:

- Billet Preparation: A special, non-dendritic alloy billet is produced, often with vigorous stirring during its initial casting to create a globular (spherical) microstructure.

- Reheating: The prepared billet is precisely reheated using an induction furnace to the semi-solid temperature range.

- Injection: The semi-solid "slug" is placed in the shot sleeve of a cold-chamber die casting machine and injected into the die cavity.

Key Advantages:

- Minimal Porosity: Because the metal is not fully liquid, there is far less turbulence during injection, which dramatically reduces gas porosity. The semi-solid state also leads to very low solidification shrinkage.

- High Precision: The controlled, less-turbulent flow allows for the creation of complex, near-net-shape parts with extremely tight tolerances and thin walls.

- Excellent Mechanical Properties: The resulting fine, uniform microstructure provides superior strength, ductility, and pressure tightness, making the parts suitable for heat treatment.

- Energy and Tooling Efficiency: Casting at lower temperatures reduces the thermal shock on the die, extending its life and consuming less energy.

I use thixocasting for high-performance applications where a combination of precision, strength, and minimal defects is required, such as in critical automotive components (e.g., steering control arms, engine mounts) and high-end electronics housings.

Low-Pressure Die Casting: Ideal for Symmetrical Aluminum Parts

Low-Pressure Die Casting (LPDC) is another variation that stands apart from its high-pressure counterpart. Instead of forcing metal into the die with high velocity, this method uses a gentle, controlled pressure to fill the mold from the bottom up. It's particularly well-suited for producing high-quality, symmetrical aluminum parts.

The process works as follows:

- Setup: The die is positioned above a sealed furnace containing molten metal. A riser tube extends from the molten metal bath up into the bottom of the die.

- Filling: A low, controlled gas pressure (typically below 15 PSI) is applied to the surface of the molten metal in the furnace. This gentle pressure forces the liquid metal to rise slowly and evenly up the riser tube and into the die cavity.

- Solidification: The pressure is maintained until the casting solidifies. This constant pressure helps feed molten metal to compensate for shrinkage, resulting in a dense, low-porosity part.

- Release: Once the part is solid, the pressure is released, and any remaining liquid metal in the riser tube flows back into the furnace.

Key Advantages:

- Reduced Turbulence: The slow, upward fill is very calm, which significantly minimizes turbulence and prevents the formation of oxides and gas porosity.

- High Metallurgical Quality: The process produces parts with excellent density, high strength, and superior structural integrity. This makes them suitable for heat treatment.

- High Yield: Because excess metal in the riser tube returns directly to the furnace, material waste is very low, often resulting in yields over 90%.

- Excellent for Symmetrical Parts: LPDC is ideal for creating axially symmetrical parts, as the bottom-up fill ensures uniform properties.

This method is my primary choice for high-integrity aluminum components like automotive wheels, suspension parts, cylinder heads, and other structural parts where strength and low porosity are critical.

My Focus on Quality Throughout the Die Casting Process

Achieving a high-quality die cast part is not a matter of chance; it's the result of a deliberate and rigorous focus on quality at every single stage of the manufacturing process. From the initial design concept to the final packaging, my approach is built on a foundation of precision, control, and continuous improvement. This commitment ensures that every component I produce is not only dimensionally accurate but also structurally sound and perfectly suited for its intended application. It's a holistic philosophy that encompasses design, materials, process control, and meticulous inspection.

Designing for Excellence: Prioritizing Quality in Die Casting

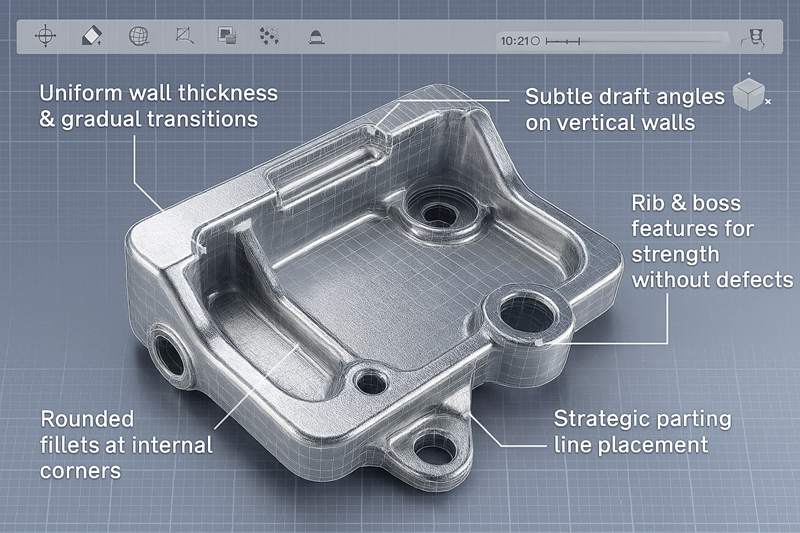

The foundation of a high-quality die cast part is laid long before any metal is melted. It begins with the design phase, where the principles of Design for Manufacturability (DFM) are paramount. DFM is a collaborative process where I work closely with clients to refine their part designs, ensuring they are optimized for the die casting process. This proactive approach accounts for up to 70% of the final product's cost and quality.

My primary DFM considerations include:

- Uniform Wall Thickness: This is one of the most critical design rules. Consistent wall thickness promotes uniform cooling and metal flow, which prevents defects like warping, sink marks, and shrinkage porosity. Where thickness changes are unavoidable, they must be gradual.

- Draft Angles: A slight taper, known as a draft angle, must be added to all walls parallel to the die's opening direction. This is essential for ensuring the part can be smoothly ejected from the mold without being damaged or causing excessive wear on the tool.

- Fillets and Radii: Sharp corners are a source of stress concentration and can impede metal flow, leading to cracks and filling issues. I incorporate generous fillets (internal rounding) and radii (external rounding) to strengthen the part and improve the flow of molten metal.

- Parting Line Placement: The parting line, where the two die halves meet, will leave a visible seam on the part. Strategic placement of this line on non-cosmetic or less critical edges is crucial for the part's final appearance and can simplify the trimming process.

- Ribs and Bosses: To add strength without increasing overall wall thickness, I often design in ribs. These features must be carefully integrated with appropriate fillets and drafts to be effective. Bosses, which serve as mounting points or standoffs, are also designed with consistent wall thickness to avoid defects.

By addressing these factors early, we can significantly reduce the risk of manufacturing defects, simplify tooling, shorten cycle times, and ultimately produce a higher-quality, more cost-effective component.

Selecting the Right Materials: High-Quality Metals for Superior Die Castings

The performance, durability, and cost-effectiveness of a die cast part are intrinsically linked to the material it is made from. Choosing the right alloy is not a one-size-fits-all decision; it requires a careful evaluation of the component's intended function, operating environment, and mechanical requirements. My process prioritizes the selection of high-purity, certified metals to ensure that every casting begins with a foundation of quality.

The Importance of Aluminum Ingots: My Foundation for Quality Die Casting

The old saying "garbage in, garbage out" is especially true in manufacturing. The quality of the final die cast part is directly dependent on the quality of the raw material. For this reason, my process begins with sourcing certified, high-purity aluminum ingots.

An aluminum ingot is a solid block of aluminum cast into a standardized shape, making it easy to handle, transport, and melt. Using high-quality ingots as the starting material offers several critical advantages:

- Consistent Chemical Composition: Certified ingots have a guaranteed chemical composition with strictly controlled levels of impurities. This consistency ensures that every batch of molten metal has predictable properties, leading to repeatable and reliable casting results.

- Reduced Defects: Impurities and excessive dissolved gases (like hydrogen) in the aluminum can lead to casting defects such as porosity, inclusions, and hot tearing. Starting with clean, pure ingots significantly minimizes these risks, resulting in stronger and more structurally sound parts.

- Predictable Performance: The mechanical properties of the final part—such as strength, hardness, and corrosion resistance—are directly tied to the purity and composition of the alloy. High-quality ingots ensure the finished component will perform as designed.

While secondary (recycled) aluminum can be used, it's crucial that it undergoes proper refinement and certification to remove contaminants. For most high-performance applications, I rely on primary or verifiably pure secondary aluminum ingots to serve as the unwavering foundation for a quality die casting process.

Choosing the Right Alloys: A380, A360, and Other Common Die Casting Materials

While starting with high-purity ingots is crucial, selecting the correct alloy for the specific application is equally important. Different aluminum alloys offer a unique combination of casting characteristics, mechanical properties, and physical attributes. My expertise lies in matching the perfect alloy to your project's needs. Here's a look at some of the most common alloys I use:

A380 Aluminum: This is the workhorse of the die casting industry, prized for its excellent balance of properties. A380 offers a fantastic combination of castability, strength, and thermal conductivity. It is relatively easy to cast, maintains its strength at high temperatures, and is very cost-effective. These qualities make it my go-to choice for a wide range of general-purpose applications, including electronic housings, engine brackets, and power tools.

A360 Aluminum: When an application demands superior corrosion resistance and strength at elevated temperatures, I turn to A360. This alloy has a higher silicon content and lower copper content compared to A380, which significantly boosts its ability to withstand harsh environments. This makes it the ideal choice for parts used in marine applications, automotive components exposed to the elements, and parts requiring excellent pressure tightness, like hydraulic cylinders. While it can be slightly more challenging to cast than A380, its enhanced performance justifies its use in demanding situations.

ADC12 (A383) Aluminum: ADC12, often referred to as A383, is a modification of A380. Its composition is tailored to improve die-filling characteristics, making it particularly suitable for parts with intricate details and complex geometries. While its mechanical properties are slightly less robust than A380's, its superior fluidity helps prevent defects in very thin-walled sections. I often select ADC12 when a design is particularly complex and complete die fill is the primary concern.

Here is a comparative table of these common alloys:

| Feature | A380 (ADC10) | A360 (ADC3) | A383 (ADC12) |

|---|---|---|---|

| Primary Strength | Best all-around balance of cost, castability, and properties | Superior corrosion resistance and high-temperature strength | Excellent die-filling for intricate parts |

| Corrosion Resistance | Good | Excellent | Good |

| Strength at High Temp. | Good | Excellent | Very Good |

| Fluidity/Castability | Excellent | Good | Excellent |

| Pressure Tightness | Good | Excellent | Good |

| Common Applications | General purpose, engine brackets, furniture, power tools | Marine parts, 5G telecom housings, automotive oil pans | Intricate components, parts with very thin walls |

By carefully analyzing the functional requirements of each part, I can select from these and other specialized alloys to ensure the final product delivers optimal performance and longevity.