The Benefits of Custom Metal Stamping Services: An Essential Guide

As experts in manufacturing, we understand the critical role that custom metal stamping services play in creating lightweight and durable metal components for various industries. This guide outlines the intricate processes, material considerations, and precision involved in delivering high-quality stamped parts. Designing components for stamping, especially with materials like aluminum, demands a thorough understanding of the process, material selection, and tooling to prevent costly redesigns and part failures. We'll explore why early consultation with a manufacturing partner, who can determine if a part is better suited for stamping or other methods like CNC machining, is crucial for success.

Understanding the Fundamentals of Custom Metal Stamping Services

Metal Stamping is a cornerstone of modern manufacturing, enabling the high-volume production of identical metal components with remarkable speed and precision. This cold-forming process is responsible for producing a vast array of parts we encounter daily, from the intricate connectors inside our electronics to major structural elements in vehicles. Understanding its fundamental principles is the first step toward leveraging its full potential.

What is Metal Stamping?

Metal stamping, also known as pressing, is a manufacturing process that uses a stamping press and a specialized tool and die to convert flat sheet metal into a specific shape. This process can involve a variety of techniques, including punching, blanking, bending, and coining, to create parts that meet exact design specifications. The process is typically performed on cold metal sheets, which helps maintain the material's inherent strength and structural integrity. Because of its efficiency, metal stamping is the go-to method for producing a high volume of identical components at a low per-unit cost.

The Core Mechanics of How Stamping Works

At its heart, the stamping process is a powerful application of force. The core mechanics involve a few key components:

- The Stamping Press: This is the main machine that provides the force. Presses can be mechanical, hydraulic, or servo-driven, each offering different levels of control over speed and pressure. Mechanical presses, which use a motor-driven flywheel to store and apply energy, are the most common type.

- The Die Set: This is the custom tooling that shapes the metal. A die set consists of an upper die (punch) and a lower die. These tools are meticulously designed using CAD software and crafted from hard, wear-resistant tool steel to ensure accuracy and longevity.

- The Sheet Metal: The raw material, typically in the form of a flat sheet or a continuous coil, is fed into the press.

During operation, the press moves the ram, which holds the upper die, down with immense force onto the sheet metal resting on the stationary lower die. This action forces the metal to shear, bend, or plastically deform, permanently taking on the shape of the die. This cycle can be repeated at very high speeds, producing hundreds or even thousands of parts per hour.

Advantages of Using Custom Metal Stamping Services

Opting for custom metal stamping services provides numerous benefits that make it a superior choice for many manufacturing projects. These advantages are especially pronounced in medium to high-volume production runs.

| Benefit | Description |

|---|---|

| Cost-Effectiveness | While initial tooling can be an investment, the high-speed nature of stamping dramatically lowers the cost per part in large production runs. The process is highly efficient, minimizing both labor time and material waste. |

| High Precision & Repeatability | Custom dies ensure that every part produced is virtually identical, adhering to extremely tight tolerances. This consistency is critical for components used in complex assemblies across industries like automotive, aerospace, and medical devices. |

| Fast Production Speeds | Stamping presses can cycle incredibly quickly, making it one of the fastest production methods available for finished a large quantity of parts. Processes like progressive die stamping allow for continuous, automated production, further shortening lead times. |

| Design Versatility & Complexity | Modern stamping techniques can create a wide variety of complex shapes, bends, curves, and features that might be difficult or more expensive to produce with other methods. Customization allows for unique parts tailored to specific application needs. |

| Enhanced Part Strength | As a cold-working process, stamping can enhance the strength of the metal through a phenomenon known as work hardening. This results in highly durable components that can withstand rigorous use. |

Potential Challenges in Metal Stamping

Despite its many advantages, metal stamping is a complex process with potential challenges that require expertise to manage. A primary consideration is the initial investment in tooling; the design and fabrication of a custom die can be costly and time-consuming, making stamping less economical for very small production runs.

Other technical challenges that engineers must address include:

- Material Springback: Metal's natural tendency to partially return to its original shape after being bent. This requires careful calculations and sometimes overbending to achieve the desired final angle.

- Tool Wear: The immense forces and repetitive nature of stamping cause gradual wear on the dies, which can affect part accuracy and lead to defects like burrs. Regular maintenance and using high-quality tool materials are essential for mitigation.

- Material Defects: Issues like cracking, wrinkles, or surface scratches can occur if the material properties are inconsistent or if process parameters are not properly controlled. Selecting the right material and calibrating the process are key to avoiding these defects.

- Burr Formation: The shearing action of stamping can leave a rough, sharp edge known as a burr on the part. While it can be minimized with proper die clearance and maintenance, some applications may require a secondary deburring process.

Successfully navigating these challenges is where the value of an experienced custom metal stamping partner truly becomes apparent.## Exploring the Versatility of Aluminum in Custom Metal Stamping Services

While metal stamping can be used with a wide range of materials, including steel, brass, and copper, aluminum has become an increasingly popular choice across many industries. Its unique combination of properties makes it exceptionally well-suited for the stamping process and for applications where performance and efficiency are paramount. Understanding aluminum's advantages and the nuances of working with it is key to unlocking its full potential in manufacturing.

Why Aluminum is a Preferred Material for Stamping

Aluminum's rise in popularity is no accident; it offers a compelling set of characteristics that make it ideal for a multitude of stamped components. It is a relatively soft metal with remarkable workability, yet it can be alloyed to achieve impressive strength.

Here are the primary reasons why aluminum is often selected for custom stamping projects:

- Impressive Strength-to-Weight Ratio: Aluminum is approximately one-third the weight of steel but can be alloyed to exhibit exceptional strength and durability. This makes it an indispensable material in the aerospace and automotive industries, where reducing weight is critical for improving fuel efficiency and overall performance.

- Excellent Corrosion Resistance: Aluminum naturally forms a protective oxide layer on its surface when exposed to air. This passive film is highly resistant to moisture and most chemicals, preventing rust and degradation over time. Specific alloys, like the 5xxx series, are specially formulated for superior performance in harsh saltwater environments, making them perfect for marine applications.

- High Formability and Ductility: Aluminum's inherent malleability and a low melting point allow it to be formed into complex and intricate shapes with relative ease. This flexibility is crucial for designers looking to create innovative parts for industries like consumer electronics, decorative packaging, and medical devices.

- Thermal and Electrical Conductivity: Aluminum is an excellent conductor of both heat and electricity, making it a preferred material for electrical components, connectors, heat sinks, and heat exchangers.

- Sustainability and Recyclability: Aluminum is 100% recyclable and can be reprocessed repeatedly without losing its inherent properties. Recycling aluminum saves up to 95% of the energy required to produce it from raw bauxite ore, making it an environmentally responsible choice.

Key Stamping Processes for Aluminum

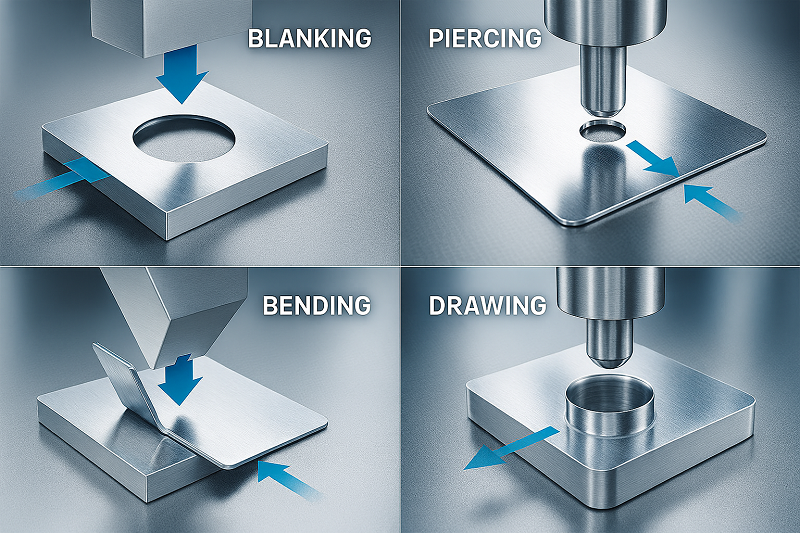

To transform a flat aluminum sheet into a functional part, several core stamping operations are utilized. These processes can be performed individually or combined in a sequence, such as in a progressive die, to create complex geometries. The four basic processes involved in stamping are blanking, piercing, bending, and drawing.

Punching and Piercing

Punching and piercing are both shearing operations used to create holes in a workpiece, but with a subtle distinction. Piercing is the process of creating a hole where the punched-out material, called a slug, is discarded as scrap. Punching, on the other hand, can sometimes refer to an operation where the piece that is cut out is the actual desired part. In both cases, a punch is forced through the metal into a die, shearing the material to create a clean opening for fasteners, wiring, or ventilation.

Blanking and Bending

Blanking is the fundamental process of cutting the outer contour of a part from a larger sheet of metal. The piece that is cut out is the workpiece, or "blank," which then moves on to other forming operations. Bending involves deforming the blank along a straight axis to create angles, V-shapes, U-shapes, or channels. The metal is placed over a die and a punch applies force, causing it to conform to the desired shape without changing its thickness. This process is essential for creating brackets, enclosures, and structural components.

Deep Drawing and Embossing

Deep drawing is a more advanced forming process used to transform a flat aluminum blank into a three-dimensional shape, such as a can, cup, or housing, where the part's depth exceeds its diameter. The aluminum sheet is drawn into a die cavity by a punch, causing it to stretch and flow into the desired shape. While aluminum is highly formable, successful deep drawing requires careful control of factors like lubrication and blank holder pressure to prevent wrinkling or tearing.

Embossing is a technique used to create a raised or recessed design in the surface of the aluminum sheet. This is achieved by pressing the material between a matching male and female die. Unlike coining, embossing does not intentionally alter the metal's thickness and is primarily used for adding decorative patterns, logos, or stiffening ribs.

Selecting the Right Aluminum Alloy for Custom Metal Stamping Services

Not all aluminum is created equal. Pure aluminum is relatively soft, so it is often mixed with other elements—such as copper, magnesium, silicon, and zinc—to create alloys with enhanced properties like increased strength or corrosion resistance. The specific alloy and its temper are critical factors that directly impact formability, final part performance, and cost.

Understanding Aluminum Alloy Grades and Elements

Wrought aluminum alloys are identified by a four-digit numbering system, where the first digit indicates the principal alloying element(s). For stamping applications, the most common series are:

- 1xxx Series (Pure Aluminum): With at least 99% aluminum content, this series is extremely ductile, workable, and corrosion-resistant. Alloy 1100 is a prime example, perfect for intricate forming jobs like decorative parts or chemical and food processing equipment.

- 3xxx Series (Manganese Alloys): The addition of manganese increases strength. Alloy 3003 is the most widely used aluminum alloy, offering a great balance of moderate strength, excellent workability, and corrosion resistance. It is commonly used for cooking utensils, fuel tanks, and sheet metal work.

- 5xxx Series (Magnesium Alloys): These alloys offer excellent corrosion resistance, especially in marine environments, along with good weldability and higher strength than the 3xxx series. Alloy 5052 is the highest strength non-heat-treatable grade, making it ideal for marine hardware, electronic chassis, and heavy-duty applications.

- 6xxx Series (Magnesium and Silicon Alloys): This is the most versatile family of heat-treatable alloys. Alloy 6061 is a jack-of-all-trades, known for its good strength, formability, weldability, and corrosion resistance. It's a top choice for automotive and aerospace structural parts.

Decoding Temper Designations (F, O, H, T, W)

The temper designation, which appears as a letter and number after the alloy grade (e.g., 6061-T6), indicates the mechanical and thermal treatment the aluminum has undergone. This treatment determines its final properties, such as hardness and ductility. The five basic temper designations are:

- F - As Fabricated: This applies to products that have acquired some degree of strain hardening from shaping processes with no special controls. Mechanical properties are not specified.

- O - Annealed: This is the softest, most ductile state of an alloy, achieved by heating it to allow the crystal structure to recrystallize. The 'O' temper provides maximum workability and is ideal for severe forming or deep drawing operations.

- H - Strain-Hardened: This designation applies to non-heat-treatable alloys that have been strengthened by cold working (rolling or stretching). A number following the 'H' indicates the degree of hardening (e.g., H14 is half-hard, H18 is full-hard).

- T - Thermally Treated (Heat-Treated): This applies to heat-treatable alloys that are strengthened through a process of solution heat treatment and aging (either natural or artificial).

- T4: Solution heat-treated and naturally aged. Offers a good combination of strength and formability.

- T6: Solution heat-treated and artificially aged. This is a very common temper that provides high strength but with reduced formability.

- W - Solution Heat-Treated: An unstable temper that applies only to alloys that age spontaneously at room temperature after solution heat treatment.

Choosing the correct alloy and temper is a critical decision that balances the need for formability during production with the strength and durability required in the final application. Early consultation with a stamping expert can help navigate these choices to ensure a successful outcome.## Advanced Techniques and Finishes in Custom Metal Stamping Services

To meet the demands of modern manufacturing for increasingly complex and high-performance parts, custom metal stamping services have evolved far beyond basic operations. Advanced stamping techniques offer greater efficiency and precision, while a wide array of finishing processes can enhance the functional and aesthetic properties of stamped components.

Utilizing Progressive Die and Transfer Die Stamping

For high-volume production, progressive die and transfer die stamping are two of the most efficient methods available. While both use a series of stations to perform multiple operations, they differ in how the part is moved through the process.

Progressive Die Stamping: In this method, a coil of metal is fed through a single, complex die set that contains multiple stations. At each station, a specific operation (like cutting, bending, or punching) is performed. The part remains attached to the carrier strip as it "progresses" through the die until the final station, where the finished component is cut off. This process is incredibly fast and cost-effective for large quantities of small to medium-sized parts, as it minimizes handling and maximizes material usage.

Transfer Die Stamping: In this process, a part is first blanked (cut) from the metal sheet and then mechanically moved from one station to the next by a "transfer" mechanism, such as robotic arms. Each station has a separate die to perform a specific function. Transfer die stamping is ideal for larger or more complex parts, like frames and structural components, that are not suitable for a progressive die. It offers more flexibility, as operations that are difficult to perform while attached to a strip (like drawing or flanging) can be easily incorporated.

Precision Fine Blanking and Four-Slide Stamping

When standard stamping doesn't meet the required level of precision, highly specialized techniques like fine blanking and four-slide stamping are employed.

Fine Blanking: This is a high-precision stamping process that produces parts with exceptionally flat surfaces and smooth, straight-sheared edges, often eliminating the need for costly secondary operations like grinding or machining. Fine blanking uses a unique triple-action press that firmly clamps the workpiece on both sides while the punch shears the material with near-zero clearance between the punch and die. This controlled process prevents material fracture and results in a full, clean-sheared edge, making it ideal for safety-critical components like gears, locking mechanisms, and automotive transmission parts.

Four-Slide/Multi-Slide Stamping: Unlike traditional vertical presses, a four-slide machine works horizontally, using four (or more) moving slides to shape the part from multiple directions simultaneously. A coil of wire or metal strip is fed into the machine, where cam-driven tools on each slide strike the material to perform a series of bends, stamps, and cuts. This method is exceptionally versatile for creating small, intricate parts with complex bends, such as clips, clamps, brackets, and electrical contacts. Because it can complete a part in a single operation, it is highly efficient and cost-effective for high-volume production.

Enhancing Stamped Parts with Surface Treatments

After a part is stamped, it often undergoes secondary finishing processes to improve its durability, corrosion resistance, and appearance. Aluminum parts, in particular, are receptive to a wide range of surface treatments.

Anodizing and Electroplating

Both anodizing and electroplating are electrochemical processes, but they work in fundamentally different ways to protect and enhance a metal surface.

Anodizing: This process is specific to certain metals like aluminum and titanium. The aluminum part is submerged in an acid electrolyte bath and an electric current is passed through it, causing a controlled oxidation process that thickens the naturally occurring oxide layer on the surface. This anodic oxide layer is extremely hard, durable, and corrosion-resistant, and it is fully integrated with the base metal, so it will not chip or peel. The porous nature of the anodized layer also allows it to be dyed in a variety of colors, making it both a protective and decorative finish.

Electroplating: This process involves depositing a thin layer of a different metal (such as nickel, chrome, silver, or gold) onto the surface of the stamped part. The part acts as the cathode in an electrolytic solution, and when an electric current is applied, metal ions from the anode are transferred and deposited onto the part's surface. Electroplating is used to improve corrosion resistance, enhance conductivity, increase surface hardness, and achieve a specific aesthetic appearance, such as a bright, reflective chrome finish.

Aesthetic Finishes: Powder Coating, Polishing, and Sandblasting

Beyond protection, many finishes are chosen for their visual appeal. These processes can create textures ranging from matte to mirror-smooth.

Powder Coating: In this process, a dry, polyester-based powder is electrostatically applied to the metal surface. The part is then cured in an oven, where the powder melts and flows into a smooth, thick, and highly durable finish. Powder coating provides excellent resistance to chipping, scratching, and corrosion, and it comes in a vast array of colors and textures. It is generally more durable and provides a thicker protective layer than traditional liquid paint.

Polishing: For a brilliant, mirror-like finish, aluminum parts can be mechanically polished. This involves using progressively finer abrasives to smooth the surface, removing any imperfections and creating a high level of reflectivity. While polished aluminum is visually striking, it requires regular maintenance to prevent oxidation and maintain its shine, unless a clear protective coating is applied.

Sandblasting: Also known as abrasive blasting, this process involves propelling abrasive media (such as glass beads, aluminum oxide, or plastic pellets) at high velocity onto the aluminum surface. Sandblasting is used to remove surface contaminants, deburr edges, and create a uniform, non-reflective matte texture. It is also an excellent pre-treatment step that creates a micro-roughened surface profile, which significantly improves the adhesion of subsequent coatings like paint or anodizing.## Applications and Problem Solving with Custom Metal Stamping Services

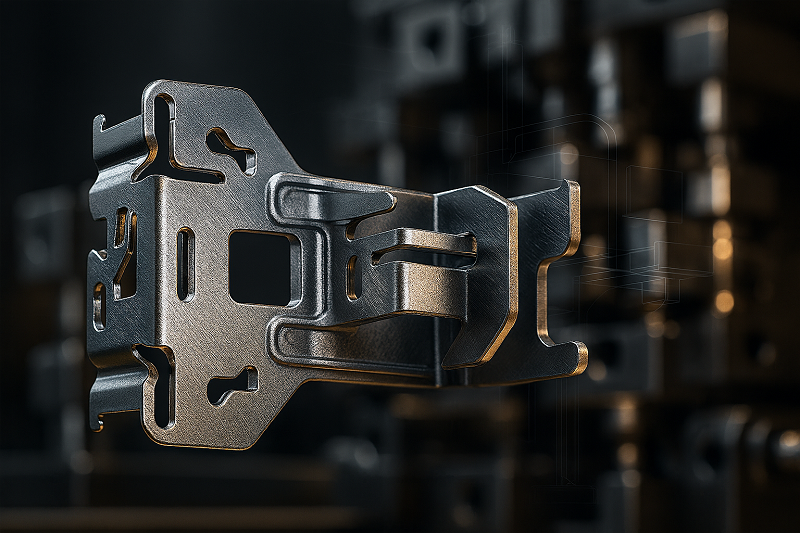

The unique combination of strength, light weight, and formability makes stamped aluminum parts indispensable across a multitude of industries. From mission-critical aerospace components to everyday consumer electronics, custom metal stamping provides solutions that drive innovation and performance. However, achieving flawless results requires a deep understanding of potential manufacturing challenges and how to solve them.

Industries Benefiting from Stamped Aluminum Parts

The versatility of stamped aluminum components has led to their widespread adoption in nearly every major industrial sector. The ability to produce durable, lightweight, and complex parts cost-effectively makes it an ideal manufacturing process.

Aerospace, Automotive, and Marine Applications

These transportation industries share a common goal: maximizing strength while minimizing weight to improve efficiency and performance.

- Aerospace: In aircraft and spacecraft, every gram matters. Stamped aluminum parts are used extensively for structural components like brackets, frames, fuselage panels, and landing gear components. The high strength-to-weight ratio and corrosion resistance of aerospace-grade aluminum alloys (such as the 6061 and 7075 series) are critical for ensuring safety and fuel efficiency.

- Automotive: The automotive industry uses stamped aluminum parts to reduce vehicle weight, which can improve fuel economy by 6-8% for every 10% reduction in weight. Components such as body panels, heat shields, engine components, and structural frames are often made from stamped aluminum to absorb impact energy and resist corrosion.

- Marine: For applications exposed to saltwater and harsh weather, the superior corrosion resistance of aluminum is a major advantage. Stamped parts from marine-grade alloys like the 5052 series are used to create fuel tanks, housings, and various fixtures that can withstand the demanding marine environment.

Medical, Electrical, and Electronic Components

In these fields, precision, reliability, and material properties are paramount.

- Medical: The medical industry relies on precision metal stamping for a vast range of devices and instruments. Stamped components are found in surgical tools, implantable devices (like pacemakers and cochlear implants), diagnostic equipment, and drug delivery systems. Titanium is often used for implantable enclosures due to its biocompatibility, but aluminum is also widely used for equipment housing, brackets, clamps, and diagnostic tools where high precision is required.

- Electrical and Electronics: Aluminum's excellent conductivity and non-magnetic properties make it ideal for electrical and electronic components. Stamped parts include EMI/RFI shields, connectors, terminals, contacts, busbars, and heat sinks. The ability to stamp complex, miniature components with tight tolerances is crucial for the ever-shrinking devices in the consumer electronics and telecommunications industries.

Addressing Common Challenges in Custom Metal Stamping Services

While metal stamping is a highly refined process, several common defects can arise. An experienced manufacturing partner can anticipate and mitigate these issues through careful planning, proper tool design, and precise process control.

Solutions for Material Deformation and Surface Defects

- Wrinkles and Buckling: These defects are wavy imperfections that can occur when compressive stresses cause the material to fold. This is often caused by insufficient blank holder force, which allows the material to flow too freely into the die. Solution: Wrinkling can be prevented by increasing the blank holder pressure, optimizing the die design with features like draw beads to control material flow, and ensuring proper lubrication.

- Surface Scratches and Scuffs: Marks on the part's surface can be caused by contaminants on the tooling or inadequate lubrication. Solution: Maintaining clean and polished tooling, using appropriate lubricants, and ensuring proper material handling procedures are essential to achieving a flawless surface finish.

Mitigating Cracks, Springback, and Edge Quality Issues

- Cracks and Tearing: Cracks can occur when the material is stretched beyond its formability limits, particularly at sharp bends or edges. This is often due to using a material with insufficient ductility, an incorrect die design with a small bend radius, or high strain rates. Solution: Selecting a more formable alloy or temper, increasing the bend radius, pre-heating the material to improve plasticity, and controlling the press speed can effectively prevent cracking.

- Springback: This is the natural tendency of a formed metal part to partially return to its original shape after the stamping pressure is removed. It is a significant challenge for dimensional accuracy, especially with high-strength materials. Solution: Springback can be compensated for by "overbending" the part slightly past the target angle. Other methods include using specialized die geometries, adjusting the forming pressure, and utilizing simulation software to predict and counteract the effect.

- Edge Quality (Burrs): Burrs are sharp, raised edges left on a part after a cutting or punching operation. They are typically caused by worn or dull tooling or incorrect clearance between the punch and die. Solution: Regular tool maintenance, including sharpening cutting edges, and ensuring the correct die clearance for the material's thickness are the primary ways to minimize burrs. In applications where even minor burrs are unacceptable, secondary processes like deburring or fine blanking can be used.

The Value of Turnkey Custom Metal Stamping Services

To navigate the complexities of design, manufacturing, and finishing, many companies choose to partner with a turnkey metal stamping provider. Turnkey manufacturing is a comprehensive approach where a single supplier handles the entire project from concept to completion.

This end-to-end service typically includes:

- Design and Engineering Consultation: Providing DFM (Design for Manufacturability) input to optimize the part for efficient production.

- In-House Tool and Die Making: Designing and fabricating the custom tooling required for the project.

- Stamping and Production: Executing the stamping operations.

- Secondary Operations: Managing all necessary post-production processes, such as heat treating, welding, assembly, and finishing.

- Quality Assurance and Inspection: Ensuring every part meets the required specifications.

- Logistics and Shipping: Handling packaging and delivery of the final product.

The benefits of a turnkey solution are significant. It streamlines the supply chain, reduces lead times by eliminating the need to coordinate with multiple vendors, and ensures consistent quality control across all stages of production. This single-point-of-contact approach simplifies project management, lowers overall costs, and ultimately leads to a higher-quality final product.

Conclusion

From concept to creation, custom metal stamping services offer an unparalleled combination of precision, efficiency, and cost-effectiveness for a vast number of applications. This guide has explored the fundamental mechanics of stamping, the unique advantages of using aluminum, the advanced techniques for complex parts, and the critical finishing processes that enhance both performance and appearance. By understanding the processes, materials, and potential challenges, manufacturers can fully leverage these services to produce high-quality, durable, and lightweight components that meet the demanding standards of modern industry.

When selecting a partner for your custom metal stamping needs, it is vital to consider their expertise, capabilities, and commitment to quality and customer service. Choosing a comprehensive, turnkey solution provider ensures a seamless production flow from the initial design consultation to the final delivery of finished parts. A professional manufacturing partner like SOMI Custom Parts, a Chinese manufacturer and supplier of metal stamping parts that also offers OEM product customization services, can guide you through every step, mitigating risks and ensuring superior results.

We encourage you to share this essential guide with your colleagues and network. What are your biggest challenges when it comes to metal component manufacturing? Share your thoughts in the comments below