The Anatomy of Precision: Why Tight Tolerances in Surgical Instrument Components are Non-Negotiable

The Unseen World of Surgical Precision

When a surgeon performs a life-saving procedure, they rely on a combination of skill, experience, and the tools in their hands. While the surgeon's expertise is visible, the incredible engineering hidden within each instrument is not. At first glance, a pair of forceps or a scalpel may seem simple. However, these tools are the products of an intense, high-stakes manufacturing process where precision is everything. The components of surgical instruments require extraordinarily tight tolerances—permissible variations in dimensions often measured in micrometers (microns). Even a minute deviation can compromise an instrument's function, risk patient safety, and turn a routine operation into a crisis. In medical manufacturing, precision isn't a goal; it's the absolute standard.

What are Precision and Tolerance in Manufacturing?

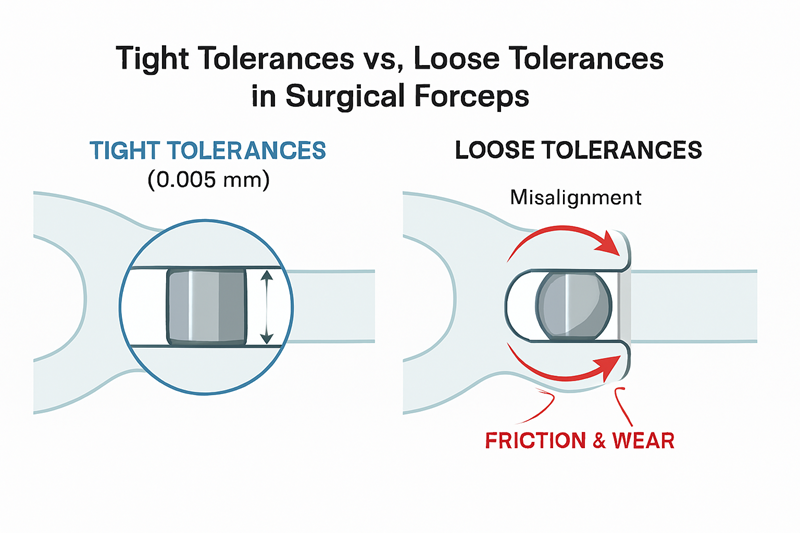

Tolerance refers to the allowable limit of variation in a part's physical dimensions. For instance, a component might be specified to be 10 millimeters in diameter with a tolerance of ±0.005 millimeters. This means any finished part measuring between 9.995 mm and 10.005 mm is acceptable. In the context of surgical instruments, these tolerances are incredibly tight. This extreme dimensional accuracy ensures that every component fits and functions perfectly with others, from the simple joint of a scissor to the complex articulating jaws of a laparoscopic device. Achieving this level of precision requires advanced machinery, controlled environments, and a deep understanding of material science.

The Critical Link Between Tight Tolerances and Patient Safety

The most important reason for strict tolerances in surgical instruments is patient safety. A slight misalignment in a needle holder could cause the needle to slip, damaging surrounding tissue. An imperfectly sharpened scalpel blade can cause a ragged incision that is more difficult to suture and has a higher risk of infection. For implantable devices, such as bone screws or plates, precise dimensions are even more critical to ensure a proper fit and prevent loosening or rejection by the body. Device failures due to out-of-tolerance components can have catastrophic consequences, making quality control a life-or-death responsibility.

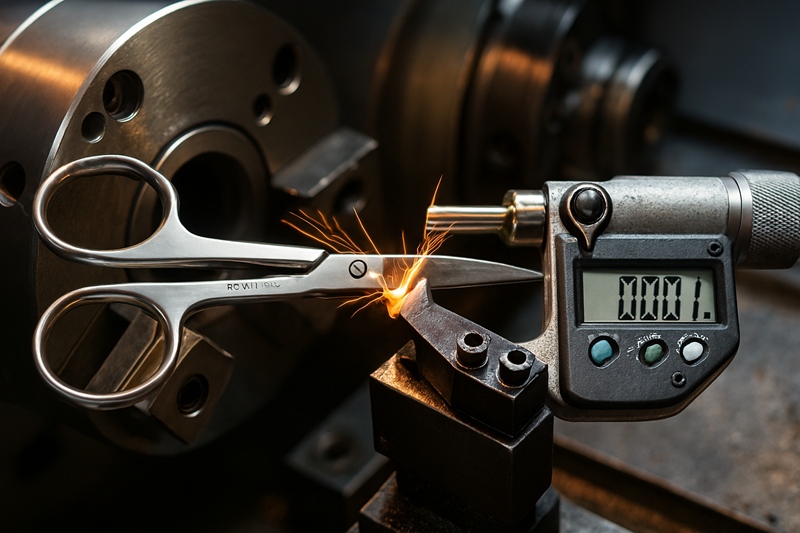

Advanced Manufacturing: CNC Machining at the Core

Achieving micron-level accuracy is impossible with traditional manual methods. Modern manufacturing relies heavily on Computer Numerical Control (CNC) machining. This process uses computer-controlled machines to cut, mill, turn, and grind materials with a level of precision that is repeatable across thousands of units. Processes like CNC milling create complex shapes for orthopedic implants, while CNC turning produces the symmetrical, cylindrical parts found in cardiovascular tools. For the most intricate designs, Electrical Discharge Machining (EDM) is used, which shapes metal using electrical sparks, allowing for the creation of delicate features without mechanical force.

The Rise of Micromachining in Modern Surgery

As surgery becomes less invasive, the instruments become smaller and more complex. Micromachining is a specialized field focused on creating miniature components with features measured in microns. This technology is the driving force behind the tools used in endoscopic, laparoscopic, and robotic-assisted surgeries. Instruments for neurosurgery, ophthalmology, and cardiology all rely on micro-manufactured parts, from tiny biopsy cups to miniature gears in robotic surgical arms. These advanced techniques enable surgeons to perform procedures with enhanced dexterity and minimal impact on the patient.

Materials Matter: The Foundation of a Flawless Instrument

The choice of material is a foundational step in quality control. Surgical instruments must be durable, corrosion-resistant, and biocompatible. The most common materials include:

- Stainless Steel: Known for its durability, resistance to corrosion, and ability to hold a sharp edge, it is a workhorse material in the operating room.

- Titanium: Often used for implants, titanium is prized for its high strength-to-weight ratio, excellent biocompatibility, and resistance to corrosion.

- Advanced Polymers & Ceramics: In certain applications, medical-grade plastics and ceramics offer benefits like light weight, non-conductivity, or extreme hardness and wear resistance.

| Material | Key Properties | Common Applications |

|---|---|---|

| Stainless Steel | Durability, Corrosion Resistance, Sterilizable | Scalpels, Forceps, Retractors, Scissors |

| Titanium | High Strength-to-Weight, Biocompatibility, Non-Magnetic | Orthopedic Implants, Dental Implants, Pacemaker Cases |

| PEEK | High-Performance Polymer, Biocompatible, Radiolucent | Spinal Cages, Suture Anchors, Dental Fixtures |

| Ceramics | Extreme Hardness, Wear Resistance, Biocompatibility | Joint Replacements, Cutting Tool Inserts |

The Importance of Surface Finish

Beyond dimensional accuracy, the surface finish of a surgical component is critical. A smooth, polished surface minimizes friction during use, prevents tissue from adhering to the instrument, and is easier to clean and sterilize. Rough surfaces can harbor bacteria, increasing the risk of post-operative infections. Processes like electropolishing and passivation are often used as final steps to create a clean, smooth, and corrosion-resistant surface, ensuring the instrument can withstand repeated sterilization cycles without degrading.

Quality Control: The Gatekeepers of Precision

Quality control in surgical instrument manufacturing is a rigorous, multi-stage process. It begins with the inspection of raw materials and continues throughout production. In-process checks using high-precision metrology equipment, such as Coordinate Measuring Machines (CMMs) and laser scanners, verify that every component meets its specified tolerances. Final inspections often occur under magnification to ensure every detail is perfect before an instrument is cleared for use. This relentless commitment to quality ensures that every tool leaving the facility is safe, reliable, and performs exactly as intended.

Regulatory Compliance: Meeting Global Standards

Surgical instruments are highly regulated medical devices. Manufacturers must adhere to stringent international standards, such as ISO 13485, which governs quality management systems for medical devices. In addition, they must meet the requirements of regulatory bodies like the FDA in the United States and obtain CE Marking for the European market. This complex regulatory landscape adds another layer of challenge but is essential for ensuring that only the safest and most effective instruments reach the hands of medical professionals.

Overcoming Manufacturing Challenges

Producing high-precision components is not without its challenges. The inherent toughness of materials like stainless steel and titanium makes them difficult to machine. Environmental factors, such as temperature fluctuations in the workshop, can cause materials to expand or contract, affecting dimensional accuracy. Therefore, top-tier manufacturers operate in climate-controlled environments and use advanced cooling lubricants and optimized cutting strategies to maintain stability and precision throughout the process. The need to balance extreme quality with cost-effectiveness also requires highly efficient, automated processes.

The Future of Surgical Instruments: A Vision of Even Greater Precision

The future of surgery points toward even smaller, smarter, and more precise instruments. Innovations in robotic surgery, nanotechnology, and smart materials are pushing the boundaries of what's possible. As procedures become more data-driven and automated, the demand for components with near-perfect accuracy and reliability will only grow. The manufacturing principles of tight tolerances and zero-defect quality control will remain the bedrock upon which these medical advancements are built, continuing their silent, yet vital, role in saving lives.