OEM vs. ODM: What's the Best Choice for Your China CNC Drilling Parts Factory?

As we navigate the complexities of manufacturing in today's global market, understanding the differences between Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) models is crucial, especially for those working with a China CNC drilling parts factory. This choice significantly impacts your product's development, time-to-market, costs, and intellectual property. Making the right decision can be a game-changer for your business, influencing everything from design control to final product delivery.

Let's explore these two manufacturing approaches to help you determine the best fit for your partnership with a China CNC drilling parts factory.

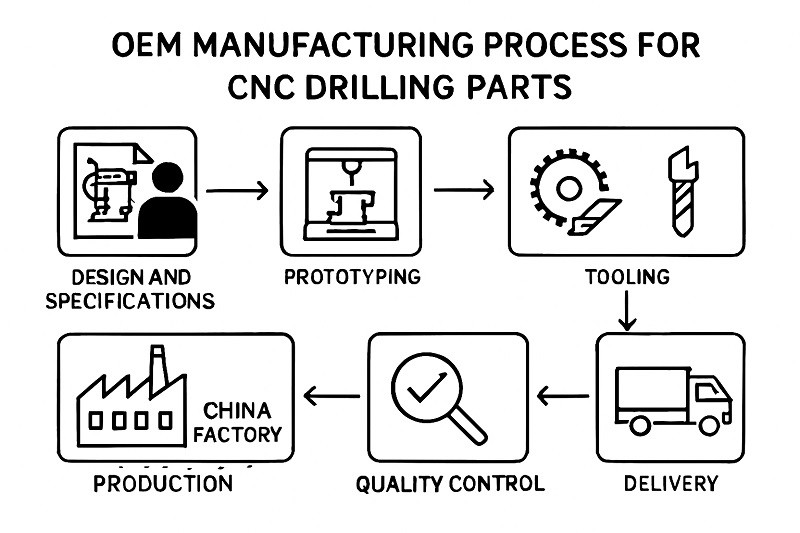

Understanding OEM for Your China CNC Drilling Parts Factory

Choosing the Original Equipment Manufacturer (OEM) route means partnering with a factory to build a product based on your own unique design and specifications. This approach is fundamental to many industries, and understanding its nuances is key to a successful collaboration with a China CNC drilling parts factory.

What is OEM Manufacturing?

An Original Equipment Manufacturer (OEM) produces goods that are used as components in the products of another company, known as a value-added reseller (VAR). In this model, you, the client, provide the complete product design, engineering specifications, and branding. The China CNC drilling parts factory then acts as your production arm, manufacturing the parts precisely to your requirements. For example, major automotive and electronics companies often rely on OEM partners to create specific components that are then assembled into their final, branded products. This relationship is business-to-business (B2B), where the OEM factory supplies you, and you, in turn, may sell to the end consumer. The key takeaway is that with OEM, you own the design and intellectual property, and the factory builds it for you.

Advantages of Choosing an OEM for Your China CNC Drilling Parts Factory

Opting for an OEM partnership offers several significant benefits, especially for businesses with a clear and innovative product vision.

- Complete Design Control and Exclusivity: The most significant advantage is that you retain full control over your product's design and intellectual property (IP). This ensures your CNC drilling parts are unique to your brand, preventing competitors from selling an identical product. This exclusivity is a powerful tool for building a strong brand identity and a competitive market position.

- Guaranteed Quality and Precision: OEM partners specialize in manufacturing and are equipped to meet exact specifications. When it comes to CNC drilling parts, where precision is paramount, this is a major asset. An OEM factory will work to your precise tolerances, ensuring each component functions perfectly within your larger system, which is crucial in sectors like aerospace, automotive, and medical devices. Better parts lead to better performance and increased product lifespan.

- Focus on Core Competencies: Outsourcing production to an OEM allows your company to concentrate on what it does best, such as research and development (R&D), product innovation, marketing, and sales. You can leverage the specialized manufacturing expertise of your Chinese partner without needing to invest in and operate your own production facility.

- Long-Term Partnership: The OEM model often fosters a deep, collaborative relationship with your manufacturer. Your factory partner becomes an integral part of your supply chain, understanding your business needs and quality standards on a profound level. This can lead to greater efficiency, faster problem-solving, and a more resilient supply chain over time.

Drawbacks of the OEM Model for China CNC Drilling Parts

Despite its advantages, the OEM path is not without its challenges and requires careful consideration.

- Higher Upfront Costs and Investment: The primary drawback is the significant initial investment in research, development, and tooling. Creating a unique design from scratch requires substantial resources, including time and money for prototyping, testing, and creating custom molds or tooling.

- Longer Time-to-Market: The extensive R&D phase, coupled with the time needed to source materials and set up production lines for a new product, naturally leads to a longer development timeline. This can be a disadvantage if speed to market is your top priority.

- Requires In-House Technical Expertise: To successfully manage an OEM partnership, your company must possess strong in-house design and engineering capabilities. You are responsible for providing flawless technical drawings and specifications, as the factory will build exactly what you provide. Any errors or omissions in the design fall on you.

- Supplier Dependency and Risk: Changing an OEM supplier can be a complex and disruptive process, as it may require transitioning your entire supply chain. Furthermore, since Chinese OEM factories often do not disclose their sub-suppliers, there's a risk they could switch component providers without informing you, potentially affecting product quality. It is vital to have robust contracts and quality control measures in place to mitigate these risks.

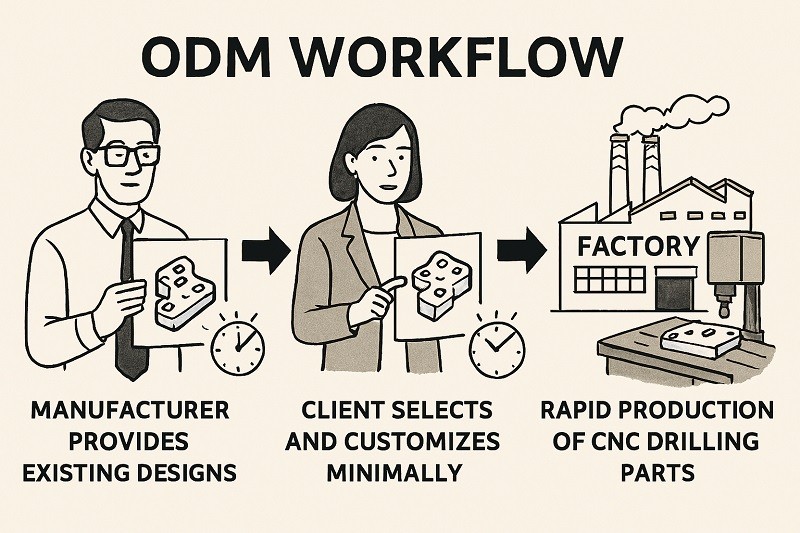

Exploring ODM for Your China CNC Drilling Parts Factory

The Original Design Manufacturer (ODM) model offers a distinct path for bringing products to market. It's an approach that prioritizes speed and efficiency by leveraging a factory's existing designs and production capabilities. For businesses considering a China CNC drilling parts factory, understanding ODM is essential for making a well-rounded decision.

What is ODM Manufacturing?

An Original Design Manufacturer (ODM) is a company that both designs and manufactures a product. This product is then sold to other companies, who rebrand it as their own. This is often referred to as "private labeling" or "white labeling". In this scenario, the China CNC drilling parts factory would have a portfolio of pre-designed parts that you can choose from. You can then request minor modifications—such as changes to the material finish, color, or packaging—and apply your own brand logo. Unlike the OEM model where you provide the design, in ODM, you leverage the manufacturer's existing product and R&D. The factory owns the intellectual property of the core design.

Benefits of Opting for an ODM with a China CNC Drilling Parts Factory

The ODM model is particularly attractive for businesses that need to move quickly and efficiently.

- Faster Time-to-Market: This is arguably the biggest advantage. Since the product design, development, and tooling are already complete, production can begin almost immediately. This allows you to launch your product and capitalize on market trends much faster than with the OEM model.

- Lower Development Costs: With ODM, you bypass the expensive and time-consuming R&D phase. You don't need to invest in creating technical designs, building prototypes, or funding new molds and tooling, significantly reducing your upfront financial commitment.

- Leverage Manufacturer Expertise: ODM factories have deep expertise in their specific product categories. They handle the entire process from design to quality control, ensuring the final product is reliable and has been tested. This allows you to benefit from their technical knowledge without needing a large in-house engineering team.

- Simplified Process: Ordering from an ODM is a relatively straightforward process. You select a product from their catalog, specify your minor customizations and branding, and place your order. This simplicity is ideal for startups, new importers, or businesses expanding into unfamiliar product lines.

Limitations of the ODM Approach for China CNC Drilling Parts

While the ODM model offers speed and cost savings, it comes with significant trade-offs that may not be suitable for every business.

- Limited Customization and Differentiation: Your ability to customize is usually restricted to superficial changes. The core design and functionality of the CNC drilling part will be identical or very similar to products sold to other companies by the same factory. This can make it very difficult to stand out in a crowded market.

- Lack of Intellectual Property (IP) Ownership: The ODM factory retains ownership of the product's core design and IP. This is a critical limitation. It means you don't own the product you're selling, and the factory is free to sell the same design to your direct competitors. This lack of exclusivity can lead to price wars and erodes long-term brand value.

- Potential for Quality Inconsistency: While ODMs manage quality control, their standards may vary or not align perfectly with your brand's expectations. You have less direct control over the quality assurance process compared to an OEM partnership.

- Risk of Market Saturation: Because the same base product is available to multiple brands, the market can quickly become saturated. If a particular ODM part becomes popular, you may find yourself competing against numerous other sellers with nearly identical offerings, differentiating only by brand name and price.

Key Differences: OEM vs. ODM for China CNC Drilling Parts Factory Collaboration

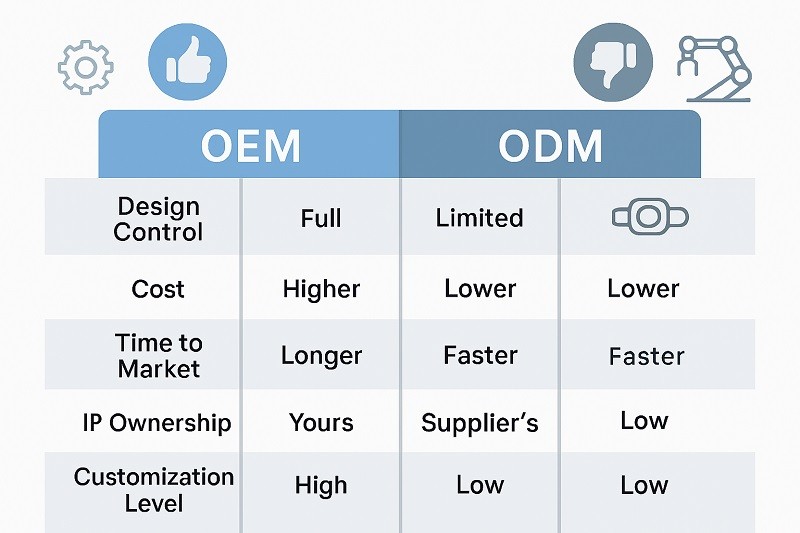

The decision to partner with an OEM or an ODM for your CNC drilling parts has far-reaching consequences. The fundamental differences between the two models lie in control, cost, speed, and ownership. Understanding these distinctions is the most critical step in choosing the right collaborative path.

Design and Intellectual Property Control

The most significant differentiator between OEM and ODM is the ownership of the design and intellectual property (IP).

OEM: In an OEM partnership, you (the client) retain full ownership of the product's design and intellectual property. You provide the detailed schematics and specifications, and the manufacturer produces the parts exclusively for you. This model is essential for businesses with patented technology or unique designs that provide a competitive advantage, as it protects your innovations.

ODM: With the ODM model, the manufacturer owns the core design and the associated IP. You are essentially selecting a pre-designed product and applying your branding. While you may request minor modifications, you do not own the underlying design of the part. This means the factory can legally sell the same base product to your competitors, creating a significant risk to your brand's uniqueness.

Cost Implications and Time-to-Market

Your budget and timeline are critical factors that will heavily influence whether OEM or ODM is the more viable option.

OEM: This path involves a higher upfront investment and a longer time-to-market. You are responsible for all research and development (R&D) costs, including design, prototyping, and tooling, which can be substantial. The development process, from concept to market-ready product, can take months or even years.

ODM: This model is characterized by lower initial costs and a much faster time-to-market. Since the manufacturer has already covered the R&D and tooling expenses, your investment is significantly lower. You can go from product selection to having branded inventory ready to sell in a fraction of the time, making ODM ideal for businesses that need to enter the market quickly.

Here is a table summarizing the key differences:

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Control | Complete control; client provides the design. | Limited control; manufacturer owns the design. |

| Intellectual Property | Client owns the IP rights. | Manufacturer owns the IP rights. |

| Upfront Costs | High (R&D, tooling, prototyping). | Low (design and tooling costs are absorbed by the manufacturer). |

| Time-to-Market | Long (extensive development process). | Fast (based on ready-made designs). |

| Customization | High; product is built to exact specifications. | Low; limited to minor changes like color and branding. |

| Product Exclusivity | High; the product is unique to your brand. | Low; competitors can sell the same base product. |

| Ideal For | Businesses with unique innovations, strong brand identity, and long-term goals. | Businesses prioritizing speed, lower initial investment, and entering new markets. |

Customization vs. Exclusivity in China CNC Drilling Parts

The final major trade-off is between how much you can tailor the product and how unique it will be in the marketplace.

OEM: The OEM model offers maximum customization. You can specify every detail of your CNC drilling part, from the exact dimensions and tolerances to the specific grade of metal and surface finish. This high level of customization results in a completely exclusive product that is unique to your brand.

ODM: Customization in the ODM model is typically superficial. You can put your logo on the part and choose a different color or packaging, but the core engineering and functionality of the part cannot be changed. This lack of deep customization means you sacrifice exclusivity. While you can get to market quickly, your product will fundamentally be a "me-too" offering, making it difficult to build lasting brand differentiation.

Making the Right Choice for Your China CNC Drilling Parts Factory

Selecting between the OEM and ODM models is a strategic decision that hinges on your business's resources, market goals, and long-term vision. Neither path is inherently superior; the "best" choice is the one that aligns with your specific circumstances.

When is OEM the Better Option?

The OEM model is the ideal choice for businesses that are playing the long game and aim to build significant brand equity. You should choose OEM if:

- You Have a Unique, Innovative Product: If your CNC drilling part has a proprietary design, patented technology, or unique features, OEM is the only way to protect your intellectual property and maintain exclusivity.

- Brand Differentiation is a Top Priority: For companies that compete on quality, innovation, and brand reputation, OEM is essential. It allows you to create a product that is entirely your own, setting you apart from the competition.

- You Have In-House Design and Engineering Resources: OEM is suitable for businesses that have the technical expertise to develop detailed product specifications and manage the design process.

- Long-Term Control Is More Important Than Short-Term Speed: If you are willing to invest the time and capital into developing a product from scratch for the long-term benefits of ownership and control, OEM is the right path. This model is common in industries like automotive, aerospace, and medical devices where precision and customization are critical.

When Does ODM Make More Sense?

The ODM model is a strategic choice for businesses that prioritize speed and cost-efficiency. ODM is the more sensible option when:

- Speed to Market is Your Primary Goal: If you want to launch a product quickly to capitalize on a market trend or establish a market presence, ODM's ready-made solutions are unbeatable.

- You Have a Limited Budget: For startups and small businesses, the high upfront costs of OEM can be prohibitive. ODM allows you to enter the market with a much smaller initial investment by avoiding R&D and tooling expenses.

- You Are Testing a New Market: If you are unsure about the demand for a product, ODM provides a low-risk way to test the waters without committing significant resources.

- The Product is a Commodity: For parts where differentiation is minimal and customers are primarily price-sensitive, the speed and cost advantages of ODM often outweigh the benefits of a custom design. This is common for consumer goods and electronics accessories.

Factors to Consider for Your China CNC Drilling Parts Factory

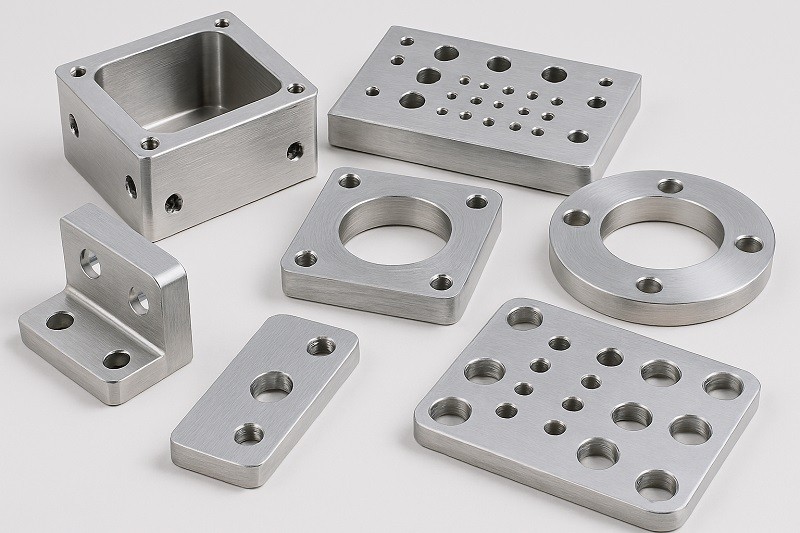

Regardless of whether you choose OEM or ODM, selecting the right manufacturing partner is crucial for success. Here are key factors to evaluate when choosing a China CNC drilling parts factory:

- Experience and Expertise: Look for a factory with a proven track record. Consider their years in business, their portfolio of past projects, and their specialization. A manufacturer with experience in your industry (e.g., automotive, aerospace) will have a better understanding of your specific requirements and standards.

- Technological Capabilities: Evaluate the factory's machinery and technology. Do they use modern, well-maintained CNC machines? Advanced equipment, such as 5-axis CNC machines, enables the production of more complex parts with tighter tolerances.

- Quality Control Systems: Quality is non-negotiable. Inquire about their quality control procedures, defect rates, and whether they hold certifications like ISO 9001. A commitment to quality is a sign of a reliable partner.

- Production Capacity and Scalability: Ensure the factory can meet your volume requirements and has the flexibility to scale production up or down as your demand changes. Discuss their lead times to prevent potential supply chain disruptions.

- Communication and Service: Effective and timely communication is essential to prevent misunderstandings and costly errors. Assess their responsiveness and their ability to clearly address technical questions and project updates.

- Material Sourcing and Expertise: A good CNC factory should be proficient in a wide range of materials, including various metals and plastics. Their ability to source high-quality materials and advise on material selection is a significant asset.

- Reputation and References: Research the factory's reputation by reading customer reviews and testimonials. Ask for references from past clients, especially those with projects similar to yours.

The Global Impact and Sustainability of China CNC Drilling Parts

The role of China's manufacturing sector extends far beyond its borders, influencing global supply chains, economic trends, and increasingly, conversations around environmental responsibility. As a key player, the CNC drilling parts industry is central to this dynamic, shaping both international trade and the push for a more sustainable future.

How China's CNC Drilling Parts Factories are Shaping International Trade

For decades, China has been the world's manufacturing powerhouse, and its CNC machining industry is a cornerstone of this reputation. The country's ability to produce high-precision components at a competitive cost has made it an indispensable partner for industries worldwide, from consumer electronics to automotive and aerospace. This dominance is built on a vast and integrated industrial ecosystem, a skilled workforce, and massive investments in infrastructure.

The global reliance on China for critical components like CNC drilling parts became especially clear during recent supply chain disruptions. These events highlighted the interconnectedness of international trade and prompted some companies to explore strategies like "nearshoring". However, the comprehensive nature of China's industrial base and its cost-effectiveness make it difficult to replace. In response to global trends and competition, China's manufacturing sector is undergoing a significant transformation. Driven by government initiatives like "Made in China 2025," there is a clear shift from low-cost, labor-intensive production to high-value, technology-driven manufacturing. This means the CNC drilling parts industry is increasingly focused on innovation, automation, and producing high-precision, complex components to meet the escalating demands of high-tech sectors.

Embracing Sustainable Practices in China CNC Drilling Parts Manufacturing

As global awareness of environmental issues grows, sustainability has become a critical factor for manufacturers and their international partners. In China, a significant push towards green manufacturing is underway, driven by government policies aiming for carbon neutrality, regulatory pressure, and market demand. This shift represents both a challenge and a significant opportunity for the CNC drilling parts industry.

Forward-thinking factories are adopting a range of eco-friendly practices to reduce their environmental impact. Key strategies include:

- Energy Efficiency: Upgrading to modern, energy-efficient CNC machines that feature intelligent controls and low-power standby modes significantly reduces electricity consumption. Some factories are also integrating renewable energy sources like solar power to further decrease their carbon footprint.

- Waste Reduction and Recycling: Precision is at the heart of CNC machining, which inherently minimizes material waste compared to traditional methods. Furthermore, leading manufacturers implement comprehensive recycling programs for scrap metal and leftover materials, turning waste into a reusable resource.

- Eco-Friendly Materials and Coolants: There is a growing trend of using recyclable raw materials and switching from traditional cutting fluids to biodegradable, eco-friendly coolants. This not only reduces pollution but also creates a safer work environment.

- Process Optimization: Using advanced software to simulate and optimize cutting paths ensures that parts are made with the least amount of material and energy possible. This digital-first approach prevents errors and reduces physical waste.

Partnering with a China CNC drilling parts factory that prioritizes sustainability is no longer just an ethical choice; it's a strategic business decision. It can lead to cost savings through resource optimization, enhance brand reputation, and ensure compliance with ever-stricter international environmental regulations.

Choosing between OEM and ODM for your China CNC drilling parts factory is a strategic decision that depends on your specific product requirements, budget, and long-term business goals. We've explored the nuances of each model to help you make an informed choice that aligns with your vision. The OEM path offers complete control and exclusivity for those with unique designs and a long-term brand focus, while the ODM path provides a rapid, cost-effective entry to the market for those prioritizing speed and efficiency.

Ultimately, the goal is to find a manufacturing partner that can best support your unique needs. Whether you prioritize complete design control or rapid market entry, understanding these models is key to success. By carefully weighing the factors of IP ownership, cost, time-to-market, and customization, you can forge a successful and lasting partnership. We encourage you to share this article with your network and leave a comment below with your own experiences or questions about OEM and ODM manufacturing.