Mastering Low-Volume CNC Machining Costs: 10 Essential Strategies for Smarter Production

Unlocking Efficiency: Why Cost Strategy Matters in Low-Volume CNC Machining

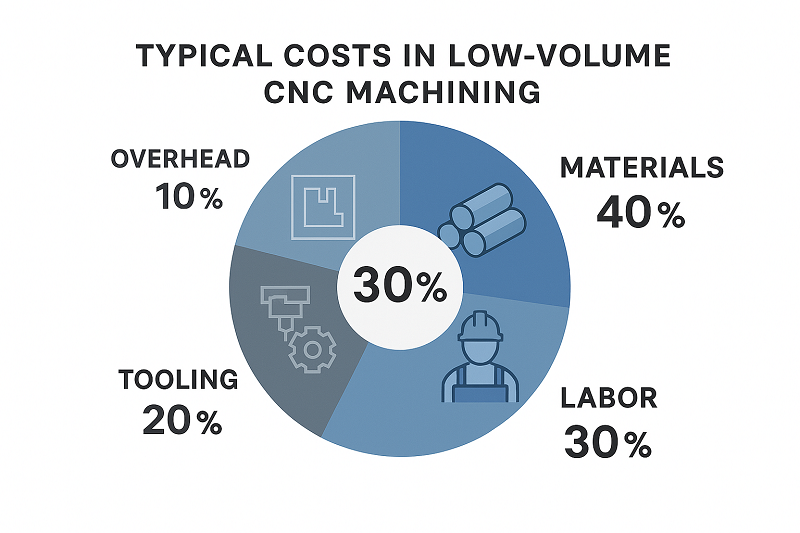

Low-volume CNC machining has revolutionized prototyping, custom part creation, and small-batch production. It provides the flexibility to manufacture anywhere from 10 to 10,000 high-precision parts without the prohibitive tooling costs associated with mass production like injection molding. However, the cost-per-unit in small batches can be high if not managed effectively. The primary cost drivers are often machine time, setup complexity, and material choice, rather than the raw materials alone.

By implementing smart, targeted cost reduction strategies, you can transform your production from expensive to economical. This article provides a comprehensive guide to mastering the economics of low-volume CNC, ensuring you get the quality you need at a price that makes sense for your project.

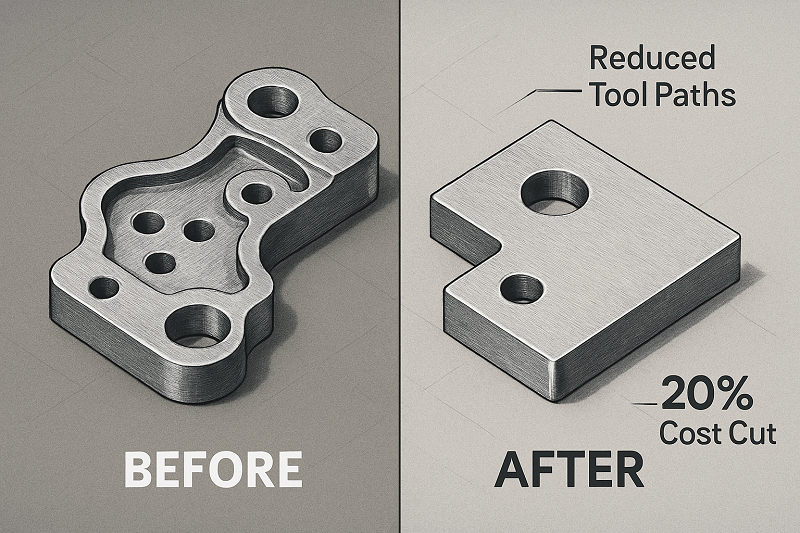

1. Optimize Your Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is the most critical step in controlling CNC machining costs. By optimizing a design for ease of manufacturing, you directly reduce machine time and complexity. Simple changes can yield significant savings.

- Simplify Geometry: Avoid complex curves, deep pockets, and unnecessary features unless they are functionally critical. Straight lines and flat surfaces are faster and cheaper to machine.

- Design for Standard Tooling: Dimension your parts to align with standard drill bit and end mill sizes. Custom sizes require special tools, which adds cost and lead time.

- Avoid Very Thin Walls: Thin walls are prone to vibration and warping during machining, which forces slower machine speeds and can lead to higher scrap rates. Aim for a minimum wall thickness of 0.8mm for metals and 1.5mm for plastics.

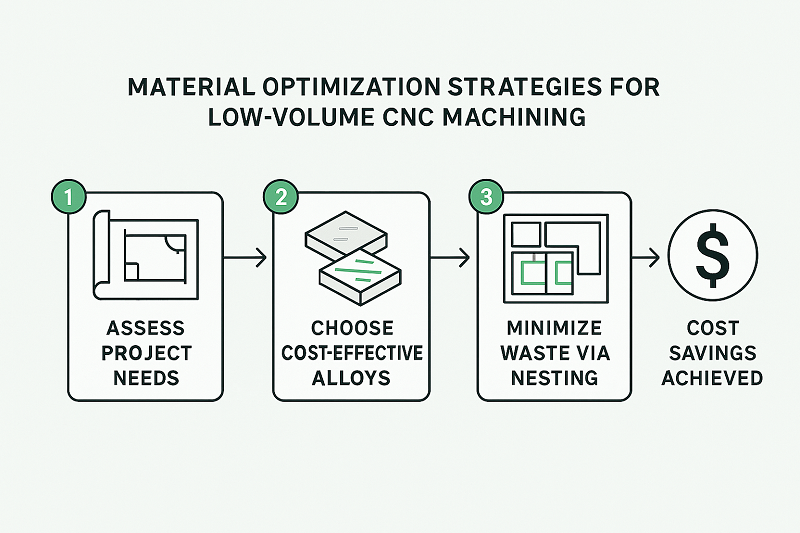

2. Choose Cost-Effective and Machinable Materials

Material selection has a profound impact on the final cost, influencing not only the raw material price but also the machining time and tool wear. Harder materials take longer to cut and wear down tools faster, increasing overall expenses.

For low-volume production, consider these factors:

- Machinability: Softer materials like Aluminum 6061 and plastics like ABS or POM (Delrin) are significantly easier and faster to machine than stainless steel or titanium.

- Availability: Using common, readily available materials reduces purchasing costs and lead times.

Here is a comparative look at common materials:

| Material | Machinability | Relative Cost | Key Benefits |

|---|---|---|---|

| Aluminum 6061 | Excellent | Low | Great strength-to-weight ratio, highly machinable. |

| Mild Steel 1018 | Good | Low | Affordable, good strength and weldability. |

| Stainless Steel 303 | Fair | Medium | Good corrosion resistance, most machinable stainless steel. |

| Brass C360 | Excellent | Medium | Extremely easy to machine, good for fittings. |

| POM (Delrin) | Excellent | Low | High stiffness, low friction, great for plastic parts. |

| ABS | Excellent | Very Low | Cost-effective, good impact resistance for prototypes. |

3. Loosen Tolerances Where Possible

Not every surface of a part requires ultra-high precision. Specifying tight tolerances only where they are functionally necessary can lead to massive cost savings. The default tolerance for most CNC machining is around ±0.127mm (±0.005"), which is sufficient for many applications.

Achieving tighter tolerances requires:

- Longer machining cycles.

- Additional, more precise finishing operations (e.g., grinding).

- More frequent and rigorous quality inspections.

- Specialized tools and more skilled labor.

Always analyze your design and relax tolerances on non-critical features.

4. Minimize Setups and Part Repositioning

Every time a part needs to be manually rotated or repositioned for machining on a different face, it adds to the labor cost and setup time. A complex part that requires a 5-axis machine or multiple setups on a 3-axis machine will be more expensive.

To reduce these costs:

- Design parts that can be machined in a single setup if possible.

- If complexity is unavoidable, consider splitting the part into multiple simpler components that can be machined separately and then assembled.

5. Design Smart Internal and External Features

The small details of your design can significantly influence machining time.

- Use Generous Internal Corner Radii: CNC tools are round, so they naturally create a radius on internal corners. A larger radius allows for a larger, more robust tool to be used, which can clear material faster. A good rule of thumb is to make the corner radius at least 1/3 of the cavity’s depth.

- Limit the Depth of Pockets: Deep pockets (where the depth is much greater than the tool's diameter) require fragile tools, slow speeds, and multiple passes to avoid tool breakage. Aim for a pocket depth of no more than four times the tool's diameter.

- Standardize Hole Sizes: Use standard hole sizes whenever possible to avoid custom drilling or milling operations. Through-holes are also cheaper than blind holes because they don't require precise depth control.

6. Simplify Finishes and Avoid Multiple Finishes

Surface finishes like anodizing, bead blasting, or powder coating add cost and time. If a part's aesthetics are not critical, an "as-machined" finish is the most economical option.

Furthermore, specifying multiple different finishes on the same part dramatically increases cost. This is because it requires extra labor for masking and additional processing steps. If multiple finishes are required, specify them only on the functionally necessary surfaces.

7. Remove Text and Lettering

Engraving or embossing text onto a part may seem like a small detail, but it requires very fine toolpaths and adds significant machining time. For branding, part numbers, or labels, consider more cost-effective alternatives applied post-machining, such as silk-screening or laser etching. If text must be machined, use a simple, sans-serif font and make it an engraved (cut) feature rather than embossed (raised).

8. Increase Order Quantity When Possible

Even in low-volume production, economies of scale apply. While setup costs are fixed for a single part or a hundred parts, ordering a larger batch allows you to spread those initial costs over more units, reducing the per-part price. If you anticipate needing more parts in the future, batching your orders can lead to significant savings.

9. Minimize Material Waste

CNC machining is a subtractive process, meaning it cuts a final shape from a larger block of raw material (the blank). The material that is cut away is waste. You can reduce material costs by designing parts that fit into standard-sized raw material stock with minimal excess. Your CAD software can help determine the smallest possible bounding box for your part, allowing your manufacturing partner to choose the most efficient blank size.

10. Partner with an Experienced CNC Machining Supplier

A knowledgeable manufacturing partner is your best asset for cost optimization. An experienced supplier can review your design and provide DFM feedback, suggesting modifications that will reduce cost without compromising function. They can also help you select the most appropriate materials and processes for your budget and application.

Conclusion: Strategic Design is the Key to Cost-Effective Production

Reducing costs in low-volume CNC machining is not about sacrificing quality; it’s about manufacturing smarter. The most significant savings are realized during the design phase. By focusing on DFM principles, making strategic material choices, and understanding the factors that drive machining time, you can effectively control your budget. Each of these strategies, from simplifying geometry to collaborating with your supplier, contributes to a more efficient and affordable production run, making your innovative projects more viable than ever.