Liquid Silicone Rubber Molding in Medical Applications: TPE vs. LSR

In the cutting-edge field of medical technology, selecting the right materials is paramount for both device functionality and patient safety. Among the numerous polymers available, two prominent options stand out for their versatility and performance: liquid silicone rubber (LSR) and thermoplastic elastomers (TPEs). Both materials offer unique advantages for a wide array of medical applications, from surgical tools to patient-contact devices.

However, understanding their distinct properties, processing methods, and ideal use cases is crucial for engineers and product designers to make informed decisions. While both are flexible, rubber-like materials, their underlying chemistry and manufacturing processes differ significantly, leading to trade-offs in performance, cost, and design complexity.

This article provides a comprehensive comparison of these versatile materials and their respective molding processes. Join us as we delve into what sets them apart, explore their specific applications, and help you navigate the complexities of material selection in medical device manufacturing to optimize both patient outcomes and production efficiency.

Understanding Liquid Silicone Rubber Molding: A Core Technology

Liquid Silicone Rubber (LSR) molding has become an indispensable manufacturing process, particularly in industries where precision, purity, and durability are non-negotiable. Its ability to produce complex, high-quality parts makes it a core technology for advanced medical devices, automotive components, and consumer electronics. By starting as a two-part liquid system that is then heat-cured, LSR offers a unique combination of design freedom and scalable, high-volume production capabilities.

What is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber, or LSR, is a high-performance thermoset elastomer derived from polysiloxane polymers. Unlike high-consistency rubber (HCR), which is processed as a solid, LSR is a two-component liquid system that is pumped, mixed, and injected into a heated mold to be cured into a final part. This system typically consists of two parts, often labeled A and B, which are mixed in a 1:1 ratio. Component A usually contains a platinum catalyst, while Component B contains the cross-linker and an inhibitor to prevent premature curing. This unique liquid state allows for highly automated and precise manufacturing through a process known as liquid injection molding (LIM).

Properties and Characteristics

LSR is renowned for its exceptional combination of physical and chemical properties, making it one of the most versatile materials in modern manufacturing. Its unique molecular structure, a backbone of alternating silicon and oxygen atoms, provides inherent stability and a host of desirable traits.

Key characteristics include:

- Biocompatibility: Medical-grade LSR is odorless, tasteless, and highly biocompatible, making it safe for devices that come into contact with human tissue and fluids. It is resistant to bacterial growth and can be sterilized using various methods, including steam autoclave, ethylene oxide (EtO), and gamma radiation.

- Extreme Temperature Resistance: LSR maintains its mechanical properties and flexibility across a broad temperature range, typically from -55°C to over 200°C (-67°F to 392°F). Some grades can even withstand temperatures up to 300°C.

- Chemical Stability: It exhibits excellent resistance to water, oxidation, UV light, and a variety of chemicals, including many acids and bases. This ensures long-term stability and reliability in demanding environments.

- Mechanical Properties: LSR offers a good balance of tensile strength, elongation, tear strength, and flexibility. A key feature is its low compression set, meaning it returns to its original shape after being compressed for an extended period, which is vital for seals and gaskets.

- Electrical Insulation: With excellent dielectric strength, LSR is a superior insulating material, widely used in electrical connectors and housings.

- Clarity and Colorability: LSR is naturally translucent, allowing for high optical clarity or easy pigmentation to match any color requirement, including custom skin tones for prosthetics.

Curing Mechanisms: Platinum vs. Peroxide

The curing process, or vulcanization, is what transforms the liquid material into a solid, elastic rubber. For silicones, the two dominant curing systems are catalyzed by either peroxide or platinum.

Peroxide Cure System: This is the older method, which uses organic peroxides that decompose at high temperatures to initiate a free-radical crosslinking reaction. While cost-effective, this process creates by-products, such as volatile organic acids, that must be removed through a post-curing step to ensure purity. These residues make peroxide-cured silicones generally unsuitable for medical applications requiring high purity and biocompatibility. The material may also exhibit slight yellowing over time.

Platinum Cure System (Addition Curing): This is the standard for medical-grade LSR. It involves an addition reaction (hydrosilylation) where a platinum catalyst enables vinyl groups to connect with hydride groups, forming a stable ethyl bridge. This process is highly efficient and produces no by-products, resulting in a purer, cleaner material that does not require extensive post-curing to remove impurities. Platinum-cured silicones offer superior transparency, improved tear strength, and better tensile and elongation properties compared to their peroxide-cured counterparts. Due to their purity and safety, they are the material of choice for healthcare applications and can meet stringent regulatory standards like ISO 10993 and USP Class VI.

The Liquid Silicone Rubber Molding Process

The liquid injection molding (LIM) process used for LSR is a highly advanced and automated manufacturing technique designed for precision and efficiency. The process begins with the two liquid components (catalyst and cross-linker) being stored in separate supply drums. From there, a metering unit pumps the two materials in a precise 1:1 ratio. Any colorants or other additives can also be introduced at this stage. The components are then fed into a static mixer, which ensures the materials are homogeneously blended without initiating the curing reaction. This mixture remains at a low temperature before being injected into a sealed, pre-heated mold cavity where the thermosetting vulcanization process takes place, rapidly curing the LSR into a solid part.

Automated Efficiency and Precision

One of the greatest advantages of LSR molding is its suitability for full automation, which significantly enhances productivity and quality. The entire process—from material dispensing to part demolding—can be robotically controlled, allowing for 24/7 production with minimal labor. This high level of automation reduces the chance of human error and contamination, leading to exceptional part-to-part consistency. The low viscosity of LSR allows it to fill complex and thin-walled sections of a mold with minimal injection pressure, ensuring high precision and the accurate replication of intricate details. Furthermore, advanced "flashless" molding techniques can be employed, which eliminate the thin, unwanted material (flash) that can seep out of the mold's parting lines, reducing material waste and eliminating secondary trimming operations.

Design Freedom in Liquid Silicone Rubber Molding

LSR molding offers product designers significantly more freedom compared to traditional thermoplastic injection molding or processing high-consistency rubber. The material's excellent flow characteristics allow for the creation of very complex geometries, thin walls, and micro-sized features that would be difficult or impossible to achieve with other elastomers.

Key design advantages include:

- Complex Geometries: LSR can easily fill intricate molds to produce parts with sophisticated details and tight tolerances.

- Thin Walls: Wall sections as thin as 0.010 inches (0.25 mm) are possible.

- Undercuts: Thanks to its flexibility, LSR allows for parts with undercuts that can often be manually or automatically de-molded without complex side-actions in the tool, simplifying mold design and reducing costs.

- Overmolding: LSR is ideal for overmolding onto thermoplastic or metal substrates to create multi-material components, such as a soft-touch grip on a rigid surgical instrument. This process creates a durable bond without the need for primers or adhesives.

This combination of automated efficiency and design flexibility makes liquid silicone rubber molding a highly reliable and cost-effective solution for producing high-performance medical components at scale.

Exploring Thermoplastic Elastomers (TPEs) in Medical Applications

Thermoplastic Elastomers (TPEs) have become a cornerstone material in medical device manufacturing, offering a revolutionary combination of rubber-like elasticity and the processing efficiency of thermoplastics. This unique dual nature has allowed TPEs to replace traditional materials like PVC, latex, and even some silicones in a multitude of applications. Their versatility, safety profile, and manufacturing advantages have made them indispensable for creating comfortable, durable, and cost-effective medical products.

What are Thermoplastic Elastomers (TPEs)?

Thermoplastic Elastomers are a class of polymers that, at room temperature, behave like vulcanized rubbers but, when heated, soften and flow like plastics. Unlike thermoset rubbers (such as LSR) which form permanent chemical cross-links during curing, TPEs have a physical cross-link structure composed of hard and soft segments. The hard thermoplastic segments provide structural integrity and processability, while the soft, amorphous elastomeric segments give the material its rubbery flexibility. This physical cross-linking is reversible, meaning the material can be melted, reprocessed, and recycled without significant degradation of its properties.

Diverse Types and Properties

The term "TPE" encompasses a broad family of materials, each with a distinct chemical composition and set of properties. The ability to tailor these formulations allows for a wide range of hardness levels, from very soft gels to semi-rigid plastics. The main types of TPEs used in the industry include:

- Styrenic Block Copolymers (TPE-S or SBC): Often based on SEBS (styrene-ethylene-butylene-styrene), these are one of the most common and versatile TPEs, known for their soft-touch feel, good flexibility, and ease of coloring. They are widely used for grips, seals, and medical tubing.

- Thermoplastic Polyolefins (TPE-O or TPO): These are blends of polypropylene (PP) and an un-crosslinked elastomer. They offer good chemical resistance and durability at a lower cost, often used in applications where a soft touch is less critical.

- Thermoplastic Vulcanizates (TPE-V or TPV): In a TPV, the elastomeric phase is dynamically vulcanized within a thermoplastic matrix. This gives them enhanced heat and chemical resistance and better compression set compared to TPOs, making them suitable for demanding seals and gaskets.

- Thermoplastic Polyurethanes (TPE-U or TPU): Known for their excellent toughness, abrasion resistance, and high tensile strength. They are often used for durable medical tubing, caster wheels, and applications requiring high wear resistance.

- Thermoplastic Copolyesters (TPE-E or COPE): These offer excellent fatigue resistance, high-temperature performance, and good chemical resistance, making them suitable for parts that undergo repeated flexing.

- Thermoplastic Polyamides (TPE-A or PEBA): TPE-A grades are prized for their flexibility at low temperatures, high strength, and good chemical resistance, making them popular in high-performance catheters and sports equipment.

Medical-grade TPEs are specifically formulated with FDA-compliant raw materials and are free from substances like phthalates, latex, and BPA, ensuring a high degree of purity and biocompatibility.

Processing Advantages of TPE Molding

The "thermoplastic" nature of TPEs is the key to their manufacturing efficiency. Because they can be melted and re-formed, they are compatible with standard, high-volume plastics processing equipment.

Key processing advantages include:

- Fast Cycle Times: TPEs solidify quickly upon cooling, allowing for much shorter injection molding cycle times compared to the chemical curing process required for thermoset rubbers like LSR. This leads to higher production output.

- Energy Efficiency: Processing temperatures for TPEs are generally lower, and no energy is needed to maintain a heat-curing reaction, resulting in lower energy consumption.

- Recyclability: Scrap material, such as runners and rejected parts, can be reground and reused, significantly reducing material waste and production costs. This makes TPE a more environmentally friendly option compared to non-recyclable thermosets.

- Overmolding: TPEs are excellent for two-shot or multi-component injection molding, where they can be chemically bonded to a wide range of rigid plastic substrates (like polypropylene, polycarbonate, and ABS) to create integrated parts with both hard and soft features.

TPE Molding Applications in Healthcare

The unique combination of properties offered by TPEs has led to their widespread adoption across the healthcare sector, particularly in applications where ergonomics and cost-efficiency are key drivers.

Ergonomics and Patient Comfort

The soft, compliant nature of TPEs makes them ideal for improving the user experience for both patients and healthcare professionals. Their pleasant, non-slip feel enhances grip and control on medical instruments, reducing user fatigue and improving safety during procedures.

Common ergonomic applications include:

- Handles and Grips: Overmolding TPE onto surgical instruments, diagnostic devices, and mobility aids provides a comfortable, secure grip.

- Patient-Contact Surfaces: The soft-touch quality of TPEs helps reduce pressure points and improve comfort in applications like respiratory masks, blood pressure cuffs, and cushioning pads on healthcare equipment.

- Wearable Devices: Skin-friendly and flexible TPEs are perfect for wearable sensors, straps, and monitoring devices that require long-term contact with the skin without causing irritation.

Cost-Effective Manufacturing Solutions

For many medical devices, TPE molding presents a highly economical alternative to other materials like silicone rubber. The primary drivers of cost savings are the material's processing efficiency and lower raw material costs. Faster molding cycles directly translate to lower per-part costs in high-volume production.

Furthermore, the ability to recycle production scrap minimizes material waste, and the compatibility with conventional injection molding machinery avoids the need for specialized equipment. TPEs have successfully replaced more expensive materials in applications such as disposable syringe plunger seals, stoppers, flexible tubing, and seals where the extreme temperature and chemical resistance of LSR may not be required. This balance of adequate performance and significant cost savings makes TPE an intelligent choice for a vast range of single-use and multi-use medical products.

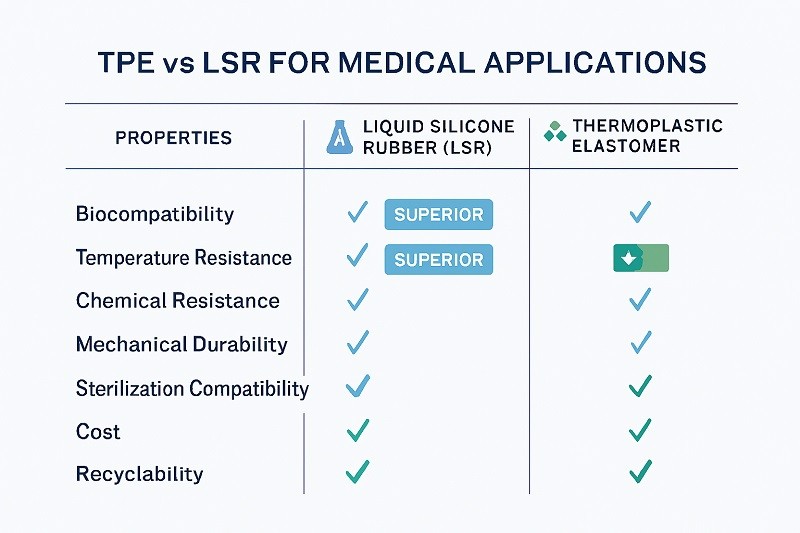

Liquid Silicone Rubber Molding vs. TPE Molding: A Direct Comparison

Choosing between Liquid Silicone Rubber (LSR) and Thermoplastic Elastomers (TPE) is a critical decision in medical device design that directly impacts performance, manufacturing cost, and patient safety. While both are flexible, rubber-like materials, their fundamental differences as a thermoset (LSR) and a thermoplastic (TPE) dictate their behavior under stress, their processing requirements, and their ideal applications. This direct comparison will provide clarity on which material is better suited for specific medical needs.

Material Properties: Performance Under Pressure

The in-service performance of a medical device often comes down to the raw properties of the material it is made from. How a material interacts with the human body, chemicals, and temperature is of paramount importance.

Biocompatibility and Safety Standards

For any material used in a medical device, biocompatibility is the foremost concern.

- LSR: Medical-grade LSR is renowned for its outstanding biocompatibility. It is inherently inert, hypoallergenic, and does not support microbial growth, making it an extremely safe choice for direct contact with skin and internal tissues. Platinum-cured LSR, in particular, is exceptionally pure as its curing process yields no by-products. This allows it to readily meet the most stringent regulatory standards, including USP Class VI and ISO 10993, making it suitable for long-term implantable devices, catheters, and infant care products.

- TPE: Medical-grade TPEs are also formulated to be biocompatible and can pass USP Class VI and ISO 10993 testing. They are free of latex, phthalates, and BPA, offering a safe alternative to PVC. However, because TPEs are compounds of various polymers and additives, their biocompatibility can vary between grades. While excellent for skin-contact devices and short-term applications like tubing and seals, they are less commonly used for long-term implants compared to LSR, as the potential for leachable or extractable compounds, though extremely low in medical grades, is a consideration.

Temperature and Chemical Resistance

Medical devices are frequently subjected to extreme temperatures during sterilization and exposure to various chemicals during use and cleaning.

- LSR: LSR offers superior performance in both high- and low-temperature environments. It maintains its properties and stability at temperatures ranging from approximately -50°C to 250°C (-58°F to 482°F), making it ideal for devices that undergo repeated steam autoclave sterilization. Its inorganic silicone-oxygen backbone also gives it excellent resistance to a wide array of chemicals, oils, and UV radiation, ensuring it does not degrade over time.

- TPE: TPEs have a more limited temperature range, typically functioning between -30°C to 150°C (-22°F to 302°F), depending on the specific grade. They generally do not withstand high-temperature sterilization methods like autoclaving as well as LSR does, potentially softening or deforming. While they offer good resistance to many aqueous solutions, acids, and bases, they can be vulnerable to degradation from certain oils, solvents, and prolonged UV exposure.

| Property | Liquid Silicone Rubber (LSR) | Thermoplastic Elastomer (TPE) |

|---|---|---|

| Operating Temperature | -50°C to 250°C (-58°F to 482°F) | -30°C to 150°C (-22°F to 302°F) |

| Sterilization Methods | Autoclave (Steam), EtO, Gamma | EtO, Gamma (Autoclave may cause issues) |

| Chemical Resistance | Excellent (Acids, bases, solvents, oils) | Good to Moderate (Varies by grade) |

| UV Resistance | Excellent | Moderate (Requires additives) |

Mechanical Strength and Durability

The ability of a material to withstand physical stress—stretching, compression, and tearing—is crucial for its longevity.

- LSR: LSR is known for its excellent compression set, meaning it can be compressed repeatedly and will return to its original shape. This makes it the superior choice for high-performance seals, gaskets, and pump components that require a reliable, long-lasting seal. While its tensile and tear strength are generally moderate, it maintains its elasticity and flexibility over a very long service life without becoming brittle.

- TPE: TPEs can be formulated to achieve very high tensile and tear strength, often exceeding that of standard LSR. This makes them highly durable for applications involving abrasion and physical wear. However, their compression set is generally poorer than LSR, meaning they are more likely to take a permanent set (deform) under sustained pressure, which can compromise sealing performance over time.

Manufacturing Considerations: Process and Cost

Beyond material performance, the manufacturing process plays a huge role in determining the final part cost, production speed, and even design possibilities.

Molding Process and Cycle Times

The fundamental difference between a thermoset and a thermoplastic is most apparent in the molding process.

- LSR: LSR is processed via liquid injection molding (LIM), where two liquid components are mixed and then injected into a heated mold. The heat initiates an irreversible chemical curing reaction (vulcanization) that solidifies the part. This curing process takes time, typically resulting in longer cycle times (e.g., 30-120 seconds) compared to TPEs.

- TPE: TPE is processed using standard thermoplastic injection molding. Solid pellets are melted, injected into a cool mold, and then solidify upon cooling. This process requires no chemical reaction, leading to significantly faster cycle times, often just a few seconds. This speed makes TPE molding more efficient for high-volume production.

Tooling Costs and Production Volume

The upfront investment in molds (tooling) is a major cost factor.

- LSR: Molds for LSR must be manufactured to extremely tight tolerances to prevent the low-viscosity liquid from flashing (leaking out of the mold). They also need to be made from high-quality, durable steel to withstand the high processing temperatures. These requirements typically make LSR tooling more expensive than TPE tooling.

- TPE: TPE molds are generally less complex and can be made using standard tooling practices for thermoplastics. This results in lower upfront tooling costs, making TPE a more accessible option for projects with smaller budgets or lower production volumes. However, for extremely high-volume applications, the faster cycle times of TPE molding can offset higher tooling costs and result in a lower per-part price.

Recyclability and Environmental Impact

Sustainability is an increasingly important consideration in manufacturing.

- LSR: As a thermoset, LSR undergoes an irreversible chemical change during molding. This means that cured LSR scrap or end-of-life parts cannot be re-melted and recycled in the same way as thermoplastics.

- TPE: TPEs are thermoplastics, meaning production scrap and post-consumer parts can be melted down and reprocessed, significantly reducing waste. This recyclability makes TPE a more environmentally friendly choice from a materials lifecycle perspective.

In summary, the choice between LSR and TPE involves a trade-off. LSR offers unmatched performance in biocompatibility, temperature resistance, and long-term durability, justifying its higher cost for critical, high-performance applications. TPE provides a versatile, cost-effective, and highly efficient manufacturing solution for a broad range of medical devices where performance requirements are less extreme.

Key Applications for Liquid Silicone Rubber Molding and TPE Molding in Medical Devices

The distinct properties of Liquid Silicone Rubber (LSR) and Thermoplastic Elastomers (TPE) make them suitable for different, though sometimes overlapping, applications within the medical device industry. The choice of material is driven by the specific performance requirements of the component, such as the need for biocompatibility, sterilization resistance, flexibility, or cost-effectiveness.

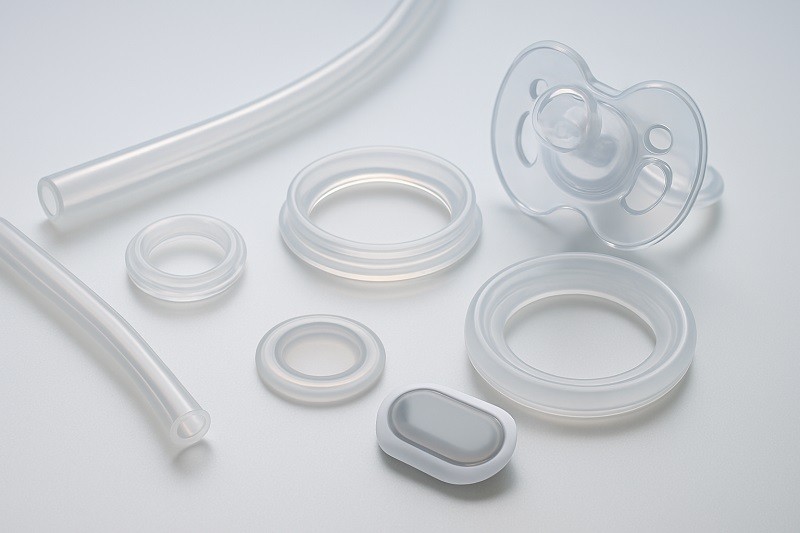

Liquid Silicone Rubber Molding Applications

The superior biocompatibility, purity, and thermal stability of LSR make it the material of choice for high-risk, critical-performance, and long-term medical applications.

Implants and Prosthetics

LSR is a go-to material for devices implanted within the human body due to its exceptional biocompatibility and resistance to degradation from bodily fluids. Its ability to be molded into complex shapes while maintaining softness and flexibility allows it to mimic natural tissue, enhancing patient comfort and device function.

- Long-Term Implants: LSR is used to manufacture devices such as heart valves, cochlear implants, soft tissue fillers, and joint implants, where long-term safety and durability are essential.

- Prosthetics: In prosthetic devices, especially for joint replacements and liners, LSR provides a comfortable, durable, and skin-safe interface that adapts to the body's movements.

Medical Tubing, Catheters, and Seals

For applications involving fluid and gas management, LSR's reliability is unparalleled. Its smooth surface reduces the risk of bacterial adhesion, while its excellent compression set ensures a durable, leak-proof seal.

- Catheters and Tubing: The flexibility, kink resistance, and chemical inertness of LSR make it ideal for urinary catheters, IV tubing, and feeding tubes, ensuring safe and comfortable use for patients.

- Seals and Gaskets: LSR is used to create high-precision seals and gaskets for infusion pumps, dialysis machines, and respiratory devices. Its ability to maintain a tight seal across a wide range of temperatures and after repeated sterilization cycles is a key advantage.

- Respiratory Devices: Given its hypoallergenic nature and excellent sealing capabilities, LSR is frequently used in CPAP masks, ventilator circuits, and oxygen delivery systems.

Surgical Instruments and Wearable Technology

The precision and durability of LSR also lend themselves to reusable surgical tools and advanced wearable devices.

- Surgical Instruments: LSR can be overmolded onto plastic or metal handles of surgical instruments to provide an ergonomic, non-slip grip that can withstand repeated autoclave sterilization. It is also used for components like valve seals and syringe components.

- Wearable Medical Technology: The skin-friendly, flexible, and durable nature of LSR is perfect for wearable devices that monitor health data, such as glucose monitors, ECG patches, and fitness trackers. The material ensures comfort for long-term wear and protects sensitive electronics. Some advanced LSR grades even incorporate conductive properties for use in smart sensors and flexible circuits.

TPE Molding Applications

TPE excels in applications where cost-efficiency, manufacturing speed, and ergonomic design are the primary considerations. It has become a popular replacement for PVC and latex in a wide range of medical products.

Handles, Grips, and Overmolded Components

The most common application for TPE in the medical field is providing a soft, tactile feel to rigid devices. Its ability to bond well with various plastics makes it ideal for overmolding.

- Ergonomic Grips: TPE is overmolded onto handles for surgical tools, diagnostic devices, and other handheld equipment to improve grip, comfort, and control for healthcare professionals, while also absorbing vibration.

- Soft-Touch Surfaces: It is used to create soft-touch buttons, non-slip feet for medical equipment, and other components where user interaction and comfort are important.

- Integrated Components: The TPE overmolding process allows for the creation of integrated parts with both structural and soft-touch features in a single, cost-effective step, eliminating the need for secondary assembly.

Respiratory Masks and Medical Tubing

For certain disposable or short-term use items, TPE offers a good balance of performance and cost.

- Respiratory Masks: TPE is used to create soft, flexible seals on respiratory and anesthesia masks, where it can provide a comfortable and effective fit against the patient's face for short-term use.

- Medical Tubing: TPE is a popular choice for various types of medical tubing, including IV sets, due to its flexibility, clarity, and kink resistance. It provides a safe, phthalate-free alternative to PVC.

Specialized Medical Packaging

TPEs are also finding use in medical and pharmaceutical packaging, where sealing and safety are critical.

- Seals and Stoppers: The good compression set and sealing properties of certain TPE grades make them suitable for syringe plunger seals, vial stoppers, and gaskets in fluid management systems.

- Flexible Packaging: TPE can be used to create durable, flexible films and containers for medical applications, offering an alternative to other plastics. TPEs meet stringent regulatory standards for safety and are used for closures, valves, and seals in pharmaceutical packaging.

Conclusion

Choosing between liquid silicone rubber molding and TPE molding for medical applications hinges on a careful assessment of specific product requirements, including performance, cost, and regulatory compliance. Each material presents a distinct profile of benefits and trade-offs that must be weighed against the intended use case.

Both materials offer compelling benefits, with liquid silicone rubber molding excelling in demanding, high-precision scenarios where biocompatibility, sterilization resistance, and long-term durability are critical. It is the clear choice for implants, high-performance seals, and reusable devices exposed to harsh conditions. TPE molding, on the other hand, provides a versatile, highly efficient, and cost-effective solution for a broad range of devices, particularly those where ergonomics, disposability, and fast production are key. Ultimately, the right choice optimizes both patient safety and manufacturing efficiency.

Whether your project demands the superior heat resistance and purity of LSR or the processing speed and recyclability of TPE, a clear understanding of these materials is crucial for success. By aligning material properties with application needs, medical device manufacturers can continue to innovate and deliver safe, effective, and high-quality products to the market. We encourage you to share this article with your colleagues and discuss how these material choices impact your own projects.