How to Choose: SLA vs. SLS vs. FDM for Your 3D Printing SLA Parts Supplier

Choosing the right 3D printing technology for your project can be a complex decision, especially when considering the nuances of Stereolithography (SLA), Selective Laser Sintering (SLS), and Fused Deposition Modeling (FDM). Each method offers unique advantages and disadvantages that directly impact part quality, cost, and lead time. This guide will help you understand the core differences to make an informed choice for your 3D printing SLA parts supplier.

As we delve into the world of additive manufacturing, we will explore how FDM, SLA, and SLS technologies stack up against each other. Additive manufacturing creates three-dimensional objects by adding material layer by layer from digital models, which reduces waste compared to traditional subtractive methods. Our goal is to equip you with the knowledge to identify the best printing process for your specific needs, ensuring optimal results for your prototypes or end-use parts. Understanding these technologies is crucial for selecting a reliable partner that can deliver on quality, speed, and cost.

Understanding the Fundamentals of FDM, SLA, and SLS when choosing your 3D Printing SLA Parts Supplier

The world of 3D printing, or additive manufacturing, is built upon a variety of technologies that construct objects layer by layer. Among the most prevalent are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each operates on a distinct principle, using different materials and processes, which in turn defines their strengths, weaknesses, and ideal applications. A foundational understanding of these three methods is the first step in a successful sourcing journey for any project, from rapid prototyping to low-volume production.

Fused Deposition Modeling (FDM): The Accessible Choice

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is one of the most common and accessible 3D printing technologies available today. Its popularity stems from its relatively low cost and user-friendly nature, making it a favorite among hobbyists, educational institutions, and businesses needing basic prototypes. Despite its simplicity, industrial-grade FDM machines are capable of producing robust parts for a variety of applications.

Process Overview and Advantages for 3D Printing SLA Parts Supplier Selection

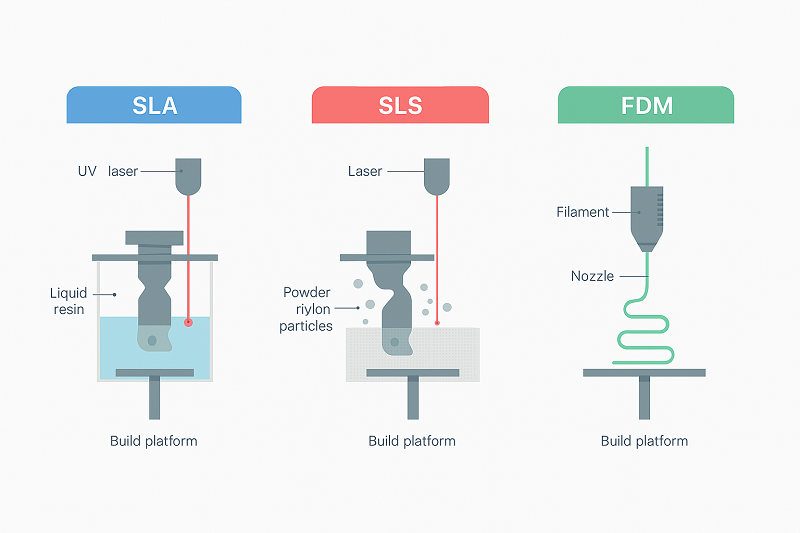

The FDM process is straightforward: a spool of thermoplastic filament is fed into a heated extruder nozzle. The printer moves this nozzle along a pre-programmed path, depositing the melted material layer by layer onto a build platform. As the material cools, it solidifies and fuses with the layer below it, gradually building the 3D object. This method is analogous to a hot glue gun meticulously drawing an object in three dimensions.

When evaluating a supplier, understanding the advantages of FDM is key:

- Cost-Effectiveness: FDM is widely regarded as the most economical 3D printing method. The printers themselves, especially desktop models, are affordable, and the thermoplastic filaments like PLA and ABS are inexpensive and widely available. This makes FDM an excellent choice for projects with tight budgets, such as early-stage prototypes and concept models.

- Speed: For simple parts, FDM can be very fast, with the ability to produce objects within minutes or hours. This accelerates the design and iteration process, allowing engineers to test form, fit, and function quickly without the long lead times associated with traditional manufacturing or other 3D printing technologies.

- Material Versatility: FDM supports a broad range of thermoplastic materials. These include common polymers like PLA (biodegradable and easy to print), ABS (durable and heat-resistant), and PETG (strong and food-safe), as well as engineering-grade materials like Nylon and TPU (flexible). Some printers can even handle composite filaments containing wood, metal, or carbon fiber for specialized properties.

- Scalability and Simplicity: The technology is scalable, with a low cost-to-size ratio, and the process is relatively simple. Post-processing is also less intensive compared to other methods; supports are often easy to remove, and the introduction of water-soluble filaments has simplified this step further.

Limitations and Considerations for your 3D Printing SLA Parts Supplier

Despite its advantages, FDM has notable limitations that a discerning client must consider when selecting a parts supplier.

- Lower Resolution and Surface Finish: The layer-by-layer extrusion process inherently creates visible layer lines, resulting in a rougher surface finish compared to SLA or SLS. This "step effect" is particularly noticeable on curved or angled surfaces and means FDM is not ideal for parts requiring fine details or cosmetic smoothness. Achieving a smooth finish often requires significant post-processing like sanding or vapor smoothing.

- Anisotropic Mechanical Properties: FDM parts are anisotropic, meaning their strength is not uniform in all directions. They are weaker along the Z-axis (between layers) than in the XY-plane because the bonds between layers are less strong than the extruded filament itself. This can make them prone to delamination or breaking under certain types of stress, limiting their use for high-strength functional applications.

- Dimensional Accuracy and Warping: FDM is susceptible to issues like warping, where the corners of a part lift off the print bed due to uneven cooling and thermal contraction. This is especially a problem with materials like ABS. Phenomena like sagging on overhangs and internal stresses can also lead to dimensional inaccuracies, requiring careful calibration and potentially an enclosed, heated build chamber for consistent results.

- Design Constraints: The need for support structures on overhangs greater than about 45 degrees is a key design constraint. These supports consume extra material, increase print time, and their removal can leave marks or damage the part's surface, affecting both aesthetics and accuracy.

When discussing a project with a potential supplier, it is vital to clarify expectations regarding surface finish, strength requirements, and tolerances to ensure FDM is the right fit.

Stereolithography (SLA): Precision and Smooth Finishes for your 3D Printing SLA Parts Supplier

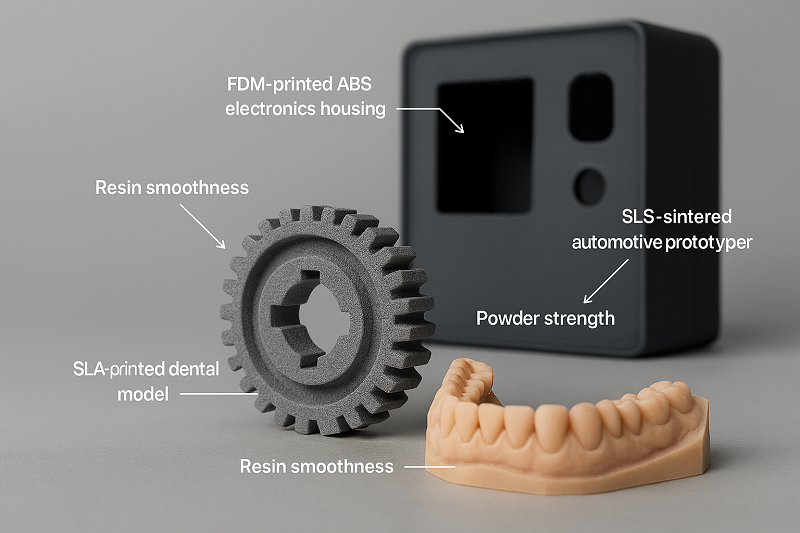

Stereolithography, or SLA, holds the title of the original 3D printing technology, first invented in the 1980s. It is a vat polymerization process renowned for its ability to produce parts with exceptionally high resolution, intricate details, and a smooth surface finish. For applications where aesthetics and precision are paramount, SLA is often the superior choice, making it a staple in fields like dentistry, jewelry, and product design for creating detailed visual prototypes and models.

How SLA Works and Its Benefits when choosing your 3D Printing SLA Parts Supplier

SLA is a vat photopolymerization process. It begins with a vat, or tank, filled with a liquid photopolymer resin. A build platform is submerged into the resin, and a UV laser beam is directed by mirrors to trace the cross-section of a single layer onto the platform. The UV light cures and solidifies the photosensitive resin it touches, a process called photopolymerization. The platform then moves—typically up by one layer's thickness—and a new layer of liquid resin flows over the previously cured surface. The laser then traces the next layer, bonding it to the one before it. This process repeats until the entire object is formed.

When evaluating a supplier for high-detail parts, the benefits of SLA are significant:

- Exceptional Precision and Detail: SLA is capable of producing parts with extremely fine details and sharp edges. Because it uses a precise laser to cure the resin, it can achieve layer heights as fine as 25 microns and can create features much smaller than an FDM nozzle can extrude. This makes it ideal for intricate designs like jewelry, dental models, and detailed figurines.

- Superior Surface Finish: SLA parts are known for their incredibly smooth, almost injection-molded quality surface finish. This is a direct result of the high-resolution printing process, which creates nearly invisible layer lines. This attribute often eliminates the need for extensive post-processing, saving time and labor.

- Material Versatility: The range of SLA resins has expanded significantly, offering a wide array of material properties. Suppliers can offer standard resins for general prototyping, tough or durable resins for functional parts, flexible resins for simulating rubber-like materials, and even biocompatible or castable resins for medical and jewelry applications. There are also clear resins for producing transparent parts.

- High Accuracy and Isotropic Parts: SLA parts are highly accurate and dimensionally stable. Furthermore, because the layers are chemically bonded as they are cured, the parts are largely isotropic, meaning they have consistent mechanical properties in all directions, unlike the anisotropic nature of FDM prints.

Key Drawbacks and Applicability for a 3D Printing SLA Parts Supplier

While powerful, SLA is not without its limitations, which must be factored into your decision when choosing a supplier.

- Higher Cost: SLA is generally more expensive than FDM. The printers themselves can be costlier, but the primary driver of cost is the liquid resin, which is significantly more expensive than F-D-M filament. This can make SLA less suitable for low-cost, high-volume projects.

- Brittleness and Material Properties: Standard SLA resins tend to produce parts that are more brittle and less impact-resistant than thermoplastics used in FDM or SLS. While tougher engineering resins are available, they come at a higher cost. The thermosetting nature of the resins means they are not ideal for functional parts that will be subjected to significant mechanical stress.

- Messy and Labor-Intensive Post-Processing: The SLA workflow can be messy and requires several post-processing steps. After printing, parts must be washed in a solvent (like isopropyl alcohol) to remove excess uncured resin. They then require a final cure in a UV curing station to achieve their optimal material properties. Additionally, like FDM, SLA requires support structures for overhanging features, which must be carefully removed, a process that can be time-consuming and potentially damage the part.

- UV Sensitivity: Parts printed with standard SLA resins can become more brittle and change color over time if exposed to UV light, such as direct sunlight. This degradation makes them less suitable for long-term outdoor applications unless they are coated or painted with a UV-protectant finish.

Therefore, SLA is most applicable for projects where visual appearance, fine detail, and surface smoothness are the highest priorities, such as high-fidelity prototypes, presentation models, and patterns for casting.

Selective Laser Sintering (SLS): Strength and Functional Parts from your 3D Printing SLA Parts Supplier

Selective Laser Sintering (SLS) is an industrial additive manufacturing technology that is highly valued for its ability to produce strong, durable, and functional parts with complex geometries. Unlike FDM and SLA, SLS does not require support structures, which grants it unparalleled design freedom. This makes it a go-to technology for functional prototyping, low-volume production of end-use parts, and creating components with intricate internal features that would be impossible to manufacture with other methods.

The SLS Process and Its Strengths in the Context of a 3D Printing SLA Parts Supplier

SLS is a powder bed fusion technology. The process starts with a thin layer of polymer powder being spread across a build platform inside a chamber that is heated to just below the material's melting point. A high-powered laser, typically a CO₂ laser, then selectively scans the cross-section of the part, sintering (fusing) the powder particles together. After the layer is complete, the build platform lowers, a new layer of powder is applied by a roller, and the process repeats. The unsintered powder in the build chamber acts as a natural support for the part, which is a key advantage.

A supplier offering SLS can provide parts with the following strengths:

- No Need for Support Structures: This is perhaps the most significant advantage of SLS. The surrounding unsintered powder supports the part during printing, eliminating the need for dedicated support structures that must be removed later. This allows for the creation of incredibly complex geometries, including interlocking parts, parts-within-parts, and intricate internal channels, that are impossible with FDM or SLA.

- Excellent Mechanical Properties and Durability: SLS parts are known for their strength, durability, and good isotropic properties, meaning they have nearly equal strength in all directions. The parts produced are often strong enough to be used as functional, end-use components and can be a viable alternative to parts made by injection molding for low-volume production.

- High Productivity and Efficiency: Because no support structures are needed, parts can be nested and stacked to fill the entire build volume of the printer. This "packing density" allows a supplier to produce many parts in a single build, making SLS highly efficient and cost-effective for small to medium production runs.

- Good Material Options for Functional Applications: While the range of materials is narrower than FDM, the available powders like nylon (PA 11, PA 12) and TPU are robust engineering thermoplastics. These materials offer excellent chemical resistance, heat resistance, and flexibility, making them suitable for demanding industrial applications like jigs, fixtures, housings, and drone components.

Challenges and Ideal Applications for a 3D Printing SLA Parts Supplier

Despite its industrial capabilities, it's important to be aware of the challenges associated with SLS when working with a parts provider.

- Higher Equipment and Material Costs: SLS printers represent a significant capital investment, and the materials are also more expensive than FDM filaments. This higher barrier to entry means that SLS is typically offered by professional service bureaus and is more costly for one-off parts compared to FDM.

- Rougher Surface Finish: SLS parts inherently have a grainy, porous surface finish, similar to the texture of fine sand. While this is acceptable for many functional parts, it is not ideal for applications requiring a smooth, cosmetic finish. Achieving a smooth surface requires post-processing steps like media polishing, vapor smoothing, or painting.

- Longer Lead Times: The SLS process includes a significant cooling period. After the printing is complete, the entire build chamber full of powder must cool down slowly—sometimes for many hours—before the parts can be excavated. This necessary cooling time can result in longer overall lead times compared to FDM or SLA.

- Powder Removal and Porosity: For parts with complex internal channels, removing all the unsintered powder can be challenging. Furthermore, the natural porosity of SLS parts means they are not inherently watertight, though this can be addressed with sealing post-processing treatments.

Given these characteristics, SLS is the ideal choice for:

- Functional Prototypes: Creating durable prototypes that need to withstand rigorous mechanical testing.

- Complex Geometries: Manufacturing parts with intricate internal features, living hinges, or snap-fit assemblies.

- Low to Mid-Volume End-Use Parts: Producing series of up to a few hundred or thousand durable parts without the high upfront cost of injection molding tooling.

- Applications Requiring High Strength and Durability: Examples include automotive components, aerospace parts, medical devices, and custom manufacturing jigs and fixtures.

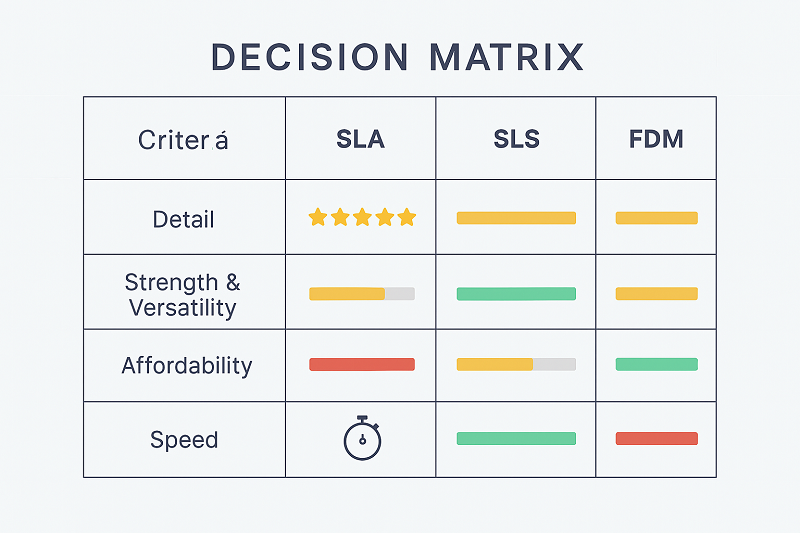

Comparing Key Performance Indicators: What Your 3D Printing SLA Parts Supplier Needs to Offer

When selecting a 3D printing technology and supplier, moving beyond the basic process is crucial. The success of your project depends on key performance indicators (KPIs) that directly influence the quality, functionality, and appearance of the final part. A competent supplier must be able to meet your specific requirements for accuracy, surface finish, mechanical strength, and material properties. This section breaks down these critical factors and compares how FDM, SLA, and SLS perform, giving you the tools to ask the right questions and set clear expectations.

Accuracy, Precision, and Tolerance: Essential for a Quality 3D Printing SLA Parts Supplier

In manufacturing, the terms accuracy, precision, and tolerance are fundamental to defining part quality. While often used interchangeably in casual conversation, they have distinct meanings in an engineering context. Understanding these concepts is vital when communicating your project's requirements to a 3D Printing Parts Manufacturer to ensure the final product meets its design intent.

Defining Accuracy, Precision, and Tolerance in 3D Printing

To have a productive conversation with a supplier, a shared vocabulary is essential.

- Accuracy: This refers to how close a printed part's dimensions are to the original CAD model's "true value." If a designed part is 50 mm long, an accurate print will be very close to 50 mm long. The closer the final measurement is to the digital design, the higher the accuracy.

- Precision: This measures the repeatability or consistency of a process. If a printer produces 10 copies of a part, and all 10 have nearly identical dimensions (even if those dimensions are not perfectly accurate to the CAD file), the process is considered precise. It signifies the reliability of the printer to produce expected results every time.

- Tolerance: This is the acceptable range of deviation from a specific dimension that you, the designer, define. A part for a simple casing might have a loose tolerance of ±0.5 mm, while a component for a mechanical assembly may require a much tighter tolerance of ±0.1 mm. Tolerance specifies how much "wiggle room" a part can have and still be considered acceptable for its intended function.

It's important to note that a printer's stated "resolution" (like layer height or XY resolution) does not directly translate to its final part accuracy. Many factors, including material properties, printer calibration, and post-processing, influence the final dimensions of a part.

How Each Technology Performs: SLA vs. SLS vs. FDM from your 3D Printing SLA Parts Supplier

The three technologies differ significantly in their ability to deliver on these metrics. The choice of technology has a direct impact on the achievable accuracy and precision of the final parts.

SLA (Stereolithography): The Leader in Accuracy SLA is widely regarded as the most accurate and precise of the three plastic 3D printing technologies.

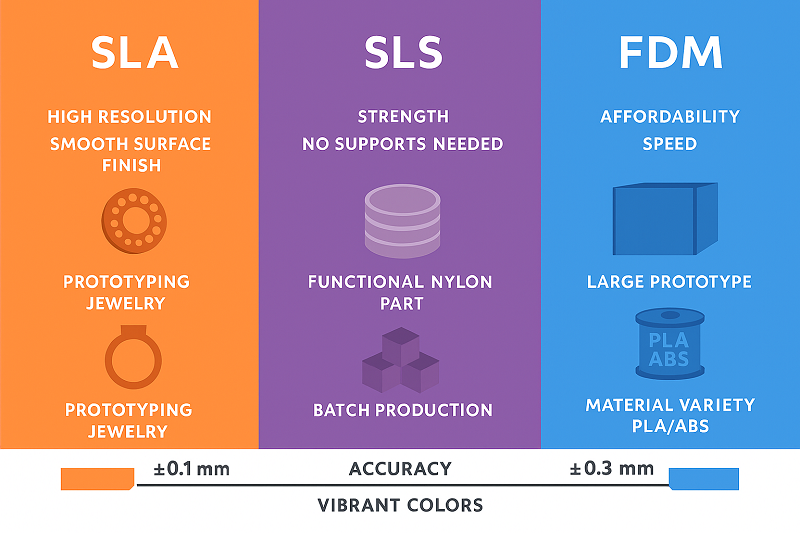

- Performance: The use of a highly-precise laser or light projector to cure liquid resin allows for extremely fine details and tight tolerances. SLA can reliably achieve high levels of repeatability due to the controlled nature of the photopolymerization process. Typical tolerances for SLA parts can be in the range of ±0.1 to ±0.2 mm, making it suitable for applications requiring close fits and intricate details.

- Why: The accuracy is a result of the high resolution of the light source, which can draw features with extreme detail. This makes SLA the best choice for visual models, high-detail prototypes, and parts where dimensional accuracy is the top priority.

SLS (Selective Laser Sintering): The Functional Middle Ground SLS offers a good balance of accuracy and strength, making it suitable for functional parts that also require decent tolerances.

- Performance: SLS uses a laser to sinter powder, which also offers good precision. However, factors like thermal shrinkage of the nylon powder as it cools can affect the final accuracy. Typical tolerances for SLS parts are often around ±0.3 mm or 3% of the part dimension, whichever is greater.

- Why: While not as pin-point accurate as SLA, SLS benefits from not needing support structures, which can otherwise affect the dimensional accuracy of surfaces they touch. It excels at producing geometrically complex but functional components where slight deviations are acceptable.

FDM (Fused Deposition Modeling): The Most Variable Performer FDM generally has the lowest dimensional accuracy and precision of the three technologies, particularly with consumer-grade machines.

- Performance: The accuracy of FDM is influenced by many variables, including nozzle size, layer height, filament quality, and material properties. Issues like filament shrinkage (especially with ABS), warping, and inconsistent extrusion can lead to deviations from the intended design. Tolerances for FDM parts are typically in the range of ±0.5 mm, which is suitable for basic prototypes but may not be sufficient for fine mechanical assemblies.

- Why: The process of extruding molten plastic is inherently less precise than using a focused light beam. While industrial FDM systems can achieve better results, they still lag behind SLA and SLS for producing highly accurate, detailed parts.

Here's a comparative table to summarize:

| Metric | SLA (Stereolithography) | SLS (Selective Laser Sintering) | FDM (Fused Deposition Modeling) |

|---|---|---|---|

| Typical Tolerance | ±0.1 mm - ±0.2 mm | ±0.3 mm | ±0.5 mm or higher |

| Key Strengths | Highest accuracy and precision, excellent for fine details. | Good balance of accuracy and strength, no supports needed. | Lowest cost, good for basic form/fit prototypes. |

| Common Issues | Post-curing shrinkage, support marks. | Thermal shrinkage, slightly grainy surface. | Warping, inconsistent extrusion, visible layer lines. |

| Best For | High-fidelity prototypes, dental/jewelry, snap-fit assemblies. | Functional prototypes, complex geometries, end-use parts. | Early-stage concept models, large and simple parts. |

When you approach a supplier, be prepared to provide a drawing with clear tolerances specified for critical features. This will allow them to determine if their machines and processes can meet your requirements and to select the most appropriate technology for the job.

Surface Finish and Detail Reproduction with Your 3D Printing SLA Parts Supplier

The aesthetic quality of a 3D printed part is often one of the first things a client notices. The surface finish and the ability to reproduce fine, intricate details are critical for visual prototypes, marketing models, and any part where appearance is a key function. Each 3D printing technology offers a vastly different outcome in this regard.

SLA: The Champion of Smoothness and Detail

When it comes to surface finish and detail, SLA is the undisputed leader.

- Surface Finish: SLA printers produce parts with the smoothest surface finish of any plastic 3D printing technology. The finish is often compared to that of injection-molded parts, with layer lines that are practically invisible to the naked eye. This is because the liquid resin is cured by a precise light source, allowing for a seamless transition between layers.

- Detail Reproduction: As the highest-resolution 3D printing technology, SLA excels at reproducing extremely fine features, sharp edges, and intricate surface textures. Its ability to create features smaller and walls thinner than FDM or even SLS makes it the perfect choice for highly detailed applications like jewelry casting patterns, dental models, and miniature figurines.

SLS: Functional Finish with Good Detail

SLS offers a compromise between the roughness of FDM and the smoothness of SLA, prioritizing function over form.

- Surface Finish: Parts printed with SLS have a characteristic matte, grainy texture. The surface is slightly rough due to the nature of the sintered powder particles. While there are almost no visible layer lines, the finish is not smooth to the touch. However, a key advantage is that the surface finish is uniform across the entire part because no support structures are needed, meaning no marks are left behind from support removal.

- Detail Reproduction: SLS can create parts with good detail, including complex internal geometries and organically curved features. It can resolve fairly small features, but very fine textures can be obscured by the inherent graininess of the surface. Its main strength is in producing complex functional parts rather than highly detailed aesthetic models.

FDM: Visible Layers and Lower Detail

FDM is at the lower end of the spectrum for both surface finish and detail reproduction.

- Surface Finish: The "hot glue gun" method of depositing material layer by layer results in prominent, visible layer lines, especially on curved or angled surfaces. This often necessitates significant post-processing like sanding or vapor smoothing to achieve a smoother appearance, which adds time and labor.

- Detail Reproduction: FDM technology struggles to reproduce very fine details. The resolution is limited by the diameter of the printer's nozzle and the control of the extrusion process. Small embossed text, intricate textures, or sharp corners can be difficult to print cleanly. FDM is best suited for less detailed, simpler geometries where surface finish is not a primary concern.

Here is a visual comparison:

| Feature | SLA (Stereolithography) | SLS (Selective Laser Sintering) | FDM (Fused Deposition Modeling) |

|---|---|---|---|

| Visual Appearance |  |

|

|

| Surface Finish | Very smooth, injection-mold like. | Matte, grainy, uniform texture. | Visible layer lines, can be rough. |

| Detail Level | Highest resolution, captures very fine details. | Good detail, excels in geometric complexity. | Lowest resolution, struggles with fine details. |

| Ideal For | Visual prototypes, aesthetic parts, miniatures. | Functional parts with complex internal features. | Basic proof-of-concept models, large simple parts. |

When discussing your project with a supplier, providing images or physical examples of the desired surface finish can be invaluable. This ensures they align their process and any necessary post-processing steps with your aesthetic expectations.

Mechanical Properties, Strength, and Durability: A Core Concern for any 3D Printing SLA Parts Supplier

For functional prototypes and end-use parts, aesthetics take a backseat to performance. Mechanical properties such as strength, durability, flexibility, and impact resistance become the defining factors. A critical concept in this area is isotropy, which describes the uniformity of a material's properties in all directions. The layered nature of 3D printing often leads to anisotropy, where parts are weaker between layers (the Z-axis) than along them (the X-Y plane).

SLS: The Leader in Strength and Functionality

For demanding applications, SLS is often the top choice due to its robust mechanical performance.

- Strength and Durability: SLS produces the strongest and most durable parts of the three technologies, with mechanical properties that can resemble those of injection-molded parts. It uses real engineering thermoplastics like Nylon PA11 and PA12, which are known for their excellent toughness, fatigue resistance, and durability.

- Isotropy: SLS parts are nearly isotropic. The high temperature within the build chamber fuses the powder particles together effectively, creating strong chemical bonds between layers. This results in parts having consistent strength in all directions, making them reliable for functional applications where loads may be unpredictable.

- Performance: The combination of strength, durability, and isotropy makes SLS parts ideal for end-use applications, high-stress functional prototypes, jigs, fixtures, and components with living hinges or snap-fit connections.

FDM: Anisotropic but with Strong Material Options

FDM's strength is highly dependent on print orientation and material choice.

- Strength and Durability: FDM can produce strong parts using engineering-grade thermoplastic filaments like ABS, PC (Polycarbonate), and Nylon. Some studies suggest that under ideal conditions, FDM parts can exhibit higher tensile strength in the XY plane than SLA parts. However, its overall performance is compromised by its anisotropic nature.

- Anisotropy: FDM parts are highly anisotropic. The mechanical bond between the extruded layers is significantly weaker than the continuous filament within a single layer. This "weak link" in the Z-axis makes FDM parts susceptible to delamination or splitting when force is applied perpendicular to the layer lines. This weakness must be considered during the design phase, orienting the part to ensure critical stresses are aligned with the stronger XY plane.

- Performance: FDM is well-suited for early-stage functional testing, jigs, and fixtures where loads are well-understood and can be accounted for in the part's orientation.

SLA: High-Detail but Often Brittle

Standard SLA parts prioritize appearance over raw strength.

- Strength and Durability: Parts made from standard SLA resins are often brittle and have lower impact strength compared to FDM or SLS thermoplastics. They can crack under significant mechanical stress. While specialized "Tough" and "Durable" resins exist to better mimic materials like ABS, they generally don't match the long-term fatigue resistance of true thermoplastics.

- Isotropy: SLA parts are considered isotropic. The photopolymerization process creates strong covalent bonds between layers as they are cured, resulting in uniform mechanical properties throughout the part. This is a significant advantage over FDM.

- Performance: Due to their potential for brittleness, standard SLA parts are best for form and fit verification, visual models, and prototypes that will not undergo high-stress testing. Engineering resins expand their applicability but come at an increased cost.

Here is a summary table for mechanical performance:

| Metric | SLS (Selective Laser Sintering) | FDM (Fused Deposition Modeling) | SLA (Stereolithography) |

|---|---|---|---|

| Primary Strength | Toughness, Durability, Fatigue Resistance | Good Tensile Strength in XY Plane | High Stiffness, but can be Brittle |

| Isotropy | Nearly Isotropic (Uniform Strength) | Highly Anisotropic (Weak between layers) | Isotropic (Uniform Strength) |

| Typical Materials | Engineering Thermoplastics (Nylon, TPU) | Standard & Engineering Thermoplastics (PLA, ABS, PC) | Photopolymer Resins (Standard, Tough, Flexible) |

| Best For | End-use functional parts, high-stress prototypes. | Low-cost functional prototypes, jigs & fixtures. | High-detail form/fit prototypes, visual models. |

When strength is a critical requirement, it is essential to discuss the specific load conditions, impact requirements, and environmental factors with your supplier so they can recommend the best technology and material combination.

Material Versatility and Post-Processing Requirements from Your 3D Printing SLA Parts Supplier

The final considerations in choosing a technology are the breadth of available materials and the complexity of the required post-processing. A wider material selection provides more options for matching your part's functional needs, while post-processing adds time and cost to the overall production workflow.

Material Versatility

- FDM: This technology boasts the widest variety of materials in the form of thermoplastic filaments. Options range from standard, easy-to-print plastics like PLA and PETG to durable, engineering-grade materials like ABS, ASA, Nylon, and Polycarbonate. Flexible (TPU) and high-performance composite filaments (e.g., carbon fiber-filled) are also readily available, making FDM highly versatile for different applications.

- SLA: SLA's main advantage in materials lies in its specialized photopolymer resins. While all are thermosets, manufacturers have developed a broad portfolio with specific properties. Options include standard resins for prototyping, "tough" or "durable" resins that simulate ABS and PP, high-temperature resins, flexible/elastic resins, and castable "wax" resins for investment casting. SLA is the only practical choice for producing truly transparent parts using clear resins. Biocompatible resins also make it a staple in the dental and medical fields.

- SLS: The material selection for SLS is the most limited of the three, primarily focused on engineering thermoplastics in powder form. The most common material is Nylon (PA11 and PA12), which is valued for its strength and durability. Other options include flexible TPU and composite materials like glass-filled or carbon-fiber-filled nylon (sometimes called "Carbonmide"). While narrow, the material selection is highly optimized for producing robust, functional, end-use parts.

Post-Processing Requirements

Nearly every 3D printed part requires some form of post-processing before it's ready for use. The complexity of these steps varies significantly between technologies.

- FDM: The primary post-processing step for FDM is support removal. For simple supports made of the same material, this involves manually breaking them away, which can leave marks that need sanding. For complex parts, using a dual-extruder printer with soluble supports simplifies this process greatly, as the supports dissolve in water or a chemical solution. To improve the rough surface finish, extensive sanding, priming, and painting may be required. Vapor smoothing can be used on certain materials like ABS to achieve a glossy, injection-molded look.

- SLA: SLA has the most involved post-processing workflow.

- Washing: After printing, the part must be washed in a solvent, typically isopropyl alcohol (IPA), to remove all sticky, uncured resin from its surface.

- Support Removal: Like FDM, SLA parts require support structures that must be carefully clipped or sanded off. Light-touch supports on modern machines make this easier and leave smaller marks.

- Post-Curing: Washed parts are not fully cured and must be placed in a UV curing chamber for a set time to achieve their final strength and stability. This final polymerization step is crucial for the part's mechanical properties.

- SLS: The workflow for SLS is different and is generally less hands-on for individual parts.

- Cooling and Breakout: The entire build chamber must cool for several hours. Once cooled, the parts are "excavated" from the block of unsintered powder.

- Cleaning/Depowdering: Excess powder must be removed from the parts, typically using compressed air or a bead-blasting station. This step must be thorough, especially for parts with internal channels.

- Finishing (Optional): Since SLS has no supports, there are no support marks to remove. The parts have a naturally grainy finish. For a smoother, sealed surface or to add color, optional steps like media tumbling, vapor smoothing, or dyeing can be applied.

This table summarizes the trade-offs:

| Technology | Material Selection | Post-Processing Workflow |

|---|---|---|

| FDM | Widest range: PLA, ABS, PETG, ASA, PC, Nylon, TPU, Composites. | 1. Support removal (manual or soluble). 2. Optional: Sanding, painting, vapor smoothing. |

| SLA | Most specialized: Standard, Tough, Durable, Flexible, Castable, High-Temp, Clear, Biocompatible resins. | 1. Wash in solvent (IPA). 2. Remove supports. 3. UV post-cure. 4. Optional: Sanding, painting. |

| SLS | Most focused: Nylon (PA11/12), TPU, Glass/Carbon-filled Nylons. | 1. Cool down and part excavation. 2. Depowdering (bead blasting). 3. Optional: Tumbling, dyeing, vapor smoothing. |

Cost and Speed Analysis: Optimizing Your Investment with a 3D Printing SLA Parts Supplier

Beyond part quality, the two most pressing concerns for any project are cost and turnaround time. The economics of 3D printing are not always straightforward, as they involve a combination of equipment, material, and labor costs. Similarly, print speed is not just about how fast a machine can move; it's also about throughput and the time spent on manual post-processing. A thorough analysis of these factors is essential to ensure you are getting the best value and efficiency from your chosen parts supplier.

Equipment and Material Costs: What to Expect from a 3D Printing SLA Parts Supplier

The total cost of a 3D printed part is determined by the underlying expenses of the equipment and the raw materials used. These costs vary drastically across the three technologies and are a primary factor in the final price you will pay a supplier.

Equipment Costs

The initial investment in 3D printing hardware is a significant factor that suppliers must account for.

- FDM: This is the most affordable technology from an equipment standpoint. Professional desktop FDM printers can range from $2,000 to $8,000, with larger industrial systems starting around $15,000. The accessibility of these machines makes FDM a widespread and cost-effective service for suppliers to offer.

- SLA: SLA printers fall into a mid-tier price range. Professional desktop resin printers typically cost between $2,500 and $10,000, while large-format industrial machines can cost upwards of $80,000 or more. The higher precision and more complex technology contribute to this increased price.

- SLS: SLS technology represents the highest capital investment. Benchtop industrial SLS systems, including necessary powder handling and cleaning stations, can cost around $60,000. Larger, traditional industrial SLS printers start at approximately $200,000. This high barrier to entry is why SLS is almost exclusively offered by dedicated service bureaus and industrial manufacturers.

Material Costs

Raw material cost is a direct and ongoing expense that significantly influences the per-part price.

- FDM: FDM filaments are the most affordable materials. Standard plastics like PLA and PETG are very economical, often costing between $20-$50 per kilogram. Even engineering-grade filaments like ABS or Nylon are relatively inexpensive, generally ranging from $50-$150/kg. This low material cost makes FDM the go-to choice for cheap prototypes and large parts.

- SLA: Liquid photopolymer resins are considerably more expensive than FDM filaments. Standard resins typically cost between $100-$200 per liter. Specialized materials, such as biocompatible, castable, or high-temperature resins, can be much pricier, sometimes reaching $200-$500 per liter. This makes material a significant cost driver for SLA parts, especially for large, solid models.

- SLS: The polymer powders used in SLS are also more expensive than FDM filaments. For example, Nylon powder costs around $100-$150 per kilogram. However, a key advantage of SLS is that unfused powder in the build chamber can be collected, refreshed with new powder, and reused in subsequent prints. This recycling capability helps lower the effective material cost per part, particularly in high-throughput environments.

Cost Summary Table

| Cost Factor | FDM (Lowest Cost) | SLA (Mid-Range Cost) | SLS (Highest Cost) |

|---|---|---|---|

| Equipment | Professional printers from $2,000. | Professional printers from $3,500. | Full systems start around $60,000. |

| Material | Standard filaments ~$50/kg. | Standard resins ~$150/L. | Nylon powder ~$100/kg (partially reusable). |

| Overall Cost/Part | Lowest. Ideal for budget-conscious projects, large parts, and rapid iteration. | Medium. Cost driven by resin price; best for high-detail parts where value justifies the expense. | High. Best value for batches of complex, functional parts where its unique capabilities are needed. |

When requesting a quote, the price will reflect not only these direct costs but also the supplier's overhead and the specific geometry of your part. Parts that are large, solid, or require high-end materials will naturally be more expensive regardless of the technology used.

Print Speed and Throughput: Maximizing Efficiency with Your 3D Printing SLA Parts Supplier

In manufacturing, time is money. The speed at which a part can be produced directly impacts lead times and project timelines. However, "print speed" is more complex than just the movement of a printhead or laser. Total turnaround time includes the actual printing duration as well as any necessary post-processing and cooling times, while throughput refers to how many parts can be produced in a given period.

Factors Influencing Print Time

Several factors determine how long a print will take, regardless of the technology:

- Part Size and Volume: Larger and more solid parts naturally take longer to print as more material needs to be processed.

- Layer Height: Thinner layers result in higher quality but increase the total number of layers required, significantly extending print time.

- Part Complexity: Intricate designs and complex geometries can slow down the printing process.

- Part Orientation: Placing a tall, thin part on its side can dramatically reduce the Z-height and therefore the print time.

Technology Speed and Throughput Comparison

FDM: The print time for FDM is highly dependent on the part's geometry and infill.

- Speed: FDM printers can be fast for small, simple parts, especially when printed with a low infill percentage (i.e., mostly hollow). However, for large, solid parts or multiple parts in a build, the time increases significantly because the nozzle must trace every line of every part sequentially.

- Throughput: The throughput for FDM is generally low. Since parts are printed one after another, producing a batch of parts takes proportionally longer.

SLA: Modern SLA printers, particularly those using DLP or MSLA technology, are extremely fast.

- Speed: Laser-based SLA printers are similar to FDM in that speed depends on how much the laser has to trace. However, DLP and MSLA printers expose an entire layer at once, meaning the print time is determined only by the part's height (number of layers), not its width or the number of parts on the build plate. This makes them exceptionally fast for producing full plates of small parts.

- Throughput: The throughput of MSLA/DLP printers is very high for small to medium-sized parts. An entire build plate full of components can be printed in the same amount of time it takes to print a single one.

SLS: SLS has a unique speed profile that favors batch production.

- Speed: A single SLS print job can take a long time—often 12 hours or more. This is due to the necessary pre-heating of the powder bed and the mandatory extended cool-down period after the print is finished. For a single, small part, SLS is by far the slowest option.

- Throughput: Where SLS excels is in throughput. Because no support structures are needed, parts can be densely nested to fill the entire build volume in all three dimensions. This allows hundreds of parts to be produced in a single print run. When the total time is divided by the number of parts, the per-part time becomes very low, making SLS the most efficient technology for batch production.

Summary of Speed and Throughput

| Metric | FDM | SLA (MSLA/DLP) | SLS |

|---|---|---|---|

| Time for a Single Part | Fast (for simple/hollow parts) | Fastest | Slowest (due to heat-up/cool-down) |

| Time for a Full Batch | Slowest (prints sequentially) | Fast (prints whole layers at once) | Medium-Fast (long build, but many parts) |

| Best Throughput For | One-off, large simple prototypes. | Batches of small, detailed parts. | Batches of functional, complex parts. |

When you need a single prototype quickly, FDM or SLA is likely the best choice. When you need to produce a short run of 50 durable components, the superior throughput of SLS will likely result in a faster overall delivery time despite the longer individual print cycle.

Labor and Post-Processing Costs: A Hidden Factor for Your 3D Printing SLA Parts Supplier

The quoted price for a 3D printed part often doesn't fully capture the total cost of production. Labor, particularly for post-processing, is a significant "hidden cost" that can greatly influence the final price you pay. The time and skill required to take a part from the printer to a finished state varies dramatically between FDM, SLA, and SLS.

FDM: The labor costs for FDM are directly tied to the complexity of the part and the desired surface finish.

- Support Removal: Manually breaking away support structures can be time-consuming and delicate work, especially for parts with intricate geometries. Using soluble supports can automate this, but it requires a more expensive dual-extruder machine and specialized support material.

- Surface Finishing: Achieving a smooth surface on an FDM print is very labor-intensive. It often requires hours of sanding, priming, and painting to hide the layer lines. For a quick prototype, these costs may be minimal, but for a presentation-quality model, the finishing labor can cost more than the print itself.

SLA: SLA's post-processing is a multi-step process that is inherently labor-intensive, though it is becoming more automated.

- Washing and Curing: Every SLA part requires washing in a solvent and then curing in a UV chamber. While automated wash and cure stations streamline this process and reduce hands-on time, it still represents a mandatory workflow step for every print.

- Finishing: Because SLA parts already have a smooth surface, they require significantly less sanding and finishing than FDM parts. Support removal is still required, but the time spent achieving a final finish is generally much lower.

SLS: The labor profile for SLS is focused on batch processing rather than individual part handling.

- Breakout and Cleaning: The most labor-intensive part of the SLS workflow is the "breakout" process—excavating the finished parts from the cake of sintered powder and cleaning them. This is typically done with compressed air or a media blasting cabinet. While it is manual work, it can be done for an entire batch of parts at once, making the per-part labor cost low.

- No Support Removal: The single biggest labor-saving advantage of SLS is the complete elimination of support structures. There is no time spent carefully cutting or breaking away supports, which dramatically reduces the hands-on time per part and makes processing complex geometries much faster.

Summary of Labor and Post-Processing Costs

| Technology | Primary Labor Driver | Cost Implication |

|---|---|---|

| FDM | Manual support removal and extensive surface finishing (sanding). | High for aesthetic parts that require a smooth finish. Low for basic prototypes where surface quality is not a concern. |

| SLA | Multi-step washing, curing, and support removal. | Medium. The process is mandatory for all parts, but a good surface finish reduces the need for extensive sanding. Automation helps lower labor costs. |

| SLS | Part breakout and depowdering (bead blasting). | Low per part. The work is done in batches, and the lack of support structures is a major time and cost saver, especially for complex designs. |

When evaluating quotes from a supplier, it's important to clarify what level of finishing is included in the price. A low initial quote for an FDM part might not include the hours of sanding needed to make it look presentable. Conversely, the higher price of an SLS part already accounts for a more streamlined post-processing workflow, potentially offering better value for complex parts in volume.

When to Choose Which Technology from Your 3D Printing SLA Parts Supplier

With a clear understanding of the fundamental processes, performance indicators, and cost structures, the final step is to match the right technology to your specific application. There is no single "best" 3D printing method; the optimal choice always depends on the project's unique priorities. Are you creating a quick, low-cost concept model? A visually stunning marketing prototype? Or a batch of durable, end-use components? This section provides clear guidelines on the ideal use cases for FDM, SLA, and SLS to help you make a decisive and effective choice.

Ideal Applications for FDM: Rapid Prototyping and Basic Models

FDM technology's primary strengths lie in its low cost and high speed for simple parts, making it the undisputed champion for specific, early-stage applications. Its accessibility allows for quick, tangible feedback on designs without a significant financial investment.

Choose FDM technology when your project requirements include:

- Rapid and Low-Cost Concept Models: FDM is the ideal choice for creating early-stage concept models and basic prototypes where the primary goal is to verify a design's form, scale, and ergonomics. Because the materials and print time are cheap, teams can afford to print multiple design iterations quickly to test ideas and make decisions. An automotive team, for example, could print several versions of a new headlight design in a single day to check its fit with the car body.

- Basic Form, Fit, and Assembly Testing: If you need to quickly check if parts of an assembly will fit together correctly, FDM provides a fast and affordable way to do so. While the tolerances aren't as tight as SLA or SLS, it is often sufficient for non-critical fit tests where the general shape and size are the main concerns.

- Large, Simple Parts: For large parts that do not require fine details or a perfect surface finish, FDM is often the most economical choice. Its scalability allows for the creation of big models that would be prohibitively expensive to print with resin or powder.

- Jigs, Fixtures, and Manufacturing Aids: On the factory floor, FDM is frequently used to create custom jigs, fixtures, and tools that improve manufacturing and assembly workflows. In this context, durability and function are more important than aesthetics, and FDM's use of strong materials like ABS and PETG makes it a perfect fit.

- Hobbyist Projects and Consumer Goods: For personal projects, cosplay items, custom organizers, or household replacement parts, FDM's affordability and ease of use are unmatched. It allows for the on-demand creation of custom items that would otherwise be difficult or expensive to obtain.

In essence, FDM excels when speed and cost take precedence over perfect surface finish, fine detail, and isotropic strength. It is a powerful tool for accelerating the earliest stages of product development and for creating functional, non-cosmetic parts in a cost-effective manner.

Ideal Applications for SLA: High-Detail Visuals and Precision Parts from Your 3D Printing SLA Parts Supplier

SLA technology shines brightest when visual perfection and dimensional accuracy are the non-negotiable priorities of a project. Its ability to produce parts with an injection-molded look and feel makes it the premier choice for applications where aesthetics and precision are paramount.

You should choose SLA when your project involves:

- High-Fidelity Visual Prototypes: For marketing materials, photoshoots, investor presentations, or user testing, SLA is unmatched. It can create concept models and cosmetic prototypes that look and feel like the final product, with smooth surfaces, crisp details, and sharp features that accurately represent the design intent.

- Intricate and Complex Geometries: SLA excels at producing parts with very fine details, such as complex surface textures, embossed text, or elaborate patterns. This makes it the ideal technology for industries like jewelry, where it's used to create detailed master patterns for lost-wax casting.

- Medical and Dental Applications: The high precision of SLA, combined with the availability of biocompatible resins, makes it a cornerstone of the medical and dental industries. It's widely used to produce highly accurate dental models, surgical guides, crowns, bridges, and patient-specific anatomical models for surgical planning.

- Miniatures, Figurines, and Scale Models: For tabletop gaming miniatures, character figurines, architectural scale models, and any application requiring extremely fine detail on a small scale, SLA is the superior choice. It can capture delicate features that would be lost with FDM or SLS.

- Precision Engineering and Fit Testing: When creating functional prototypes that require tight tolerances, such as snap-fit enclosures or complex assemblies, SLA's high dimensional accuracy ensures that parts will fit together as designed. Engineering-grade "tough" and "durable" resins can be used to add functionality to these precise prototypes.

- Clear or Transparent Parts: For applications requiring optical clarity, such as lenses, light pipes, or fluidics visualization models, SLA is the only technology that can produce truly transparent parts when used with clear resins and proper post-processing.

In summary, if your primary goal is to create a part that is visually perfect, dimensionally accurate, and features intricate details, SLA is the definitive technology to request from your parts supplier.

Ideal Applications for SLS: Functional Prototypes and End-Use Components

SLS technology is the industrial workhorse of the 3D printing world. It is the go-to choice when part strength, durability, and geometric complexity are the most important factors. Its unique process enables the creation of parts that are not only strong but would be impossible to make with traditional manufacturing.

Choose SLS technology when your project requirements include:

- High-Performance Functional Prototypes: SLS is ideal for creating robust prototypes that need to withstand rigorous real-world testing. Thanks to the excellent mechanical properties of materials like Nylon PA12, these prototypes behave like final injection-molded parts, allowing you to test for fit, mechanical loads, and function with confidence.

- Complex Geometries and Part Consolidation: The defining advantage of SLS is its ability to print without support structures. This grants unparalleled design freedom, making it perfect for manufacturing parts with intricate internal channels, living hinges, snap-fit assemblies, and complex lattice structures. It also allows multiple components of an assembly to be consolidated and printed as a single, complex part.

- Low to Mid-Volume Production of End-Use Parts: For production runs of up to a few thousand units, SLS is a highly cost-effective alternative to injection molding. It completely bypasses the high upfront cost and long lead times of creating a mold, making it perfect for bringing a product to market quickly or for producing customized, low-volume goods.

- Durable, Production-Grade Components: SLS parts are strong, temperature and chemical-resistant, and durable, making them suitable for a wide array of end-use applications across various industries. Common uses include:

- Automotive: Ducts, brackets, interior trim, and other under-the-hood components.

- Aerospace: Lightweight ductwork, brackets, and customized fixtures.

- Medical: Custom prosthetics, orthotics, and durable medical equipment housings.

- Industrial: Custom jigs, fixtures, tooling for production lines, and robotic end-of-arm tooling.

In essence, SLS is the best choice when you need to move beyond simple prototypes and produce parts that are strong enough for functional testing or for use as final products, especially when those parts feature complex designs.

Combining Technologies: A Comprehensive Approach with Your 3D Printing SLA Parts Supplier

The most strategic and cost-effective product development workflows often don't rely on a single 3D printing technology. Instead, they leverage the unique strengths of each method at different stages of the design cycle. A knowledgeable supplier can act as a crucial partner in this process, guiding you on when to use the right tool for the right job to optimize for speed, cost, and quality. This hybrid approach helps companies move faster, reduce waste, and develop better products.

A Common Hybrid Workflow

A typical and highly effective multi-technology approach might look like this:

Early Concept Validation with FDM: In the initial stages, when ideas are fluid and multiple designs need to be evaluated, FDM is the perfect tool. Use it to quickly and cheaply print basic mockups and form-study models. These prints allow you to test ergonomics, scale, and general appearance without significant investment. For example, a team can print three different handle designs in a single morning to see which one feels best.

Aesthetic and Fit Prototypes with SLA: Once the basic form is locked down from FDM models, the next step is to create a high-fidelity visual prototype using SLA. This part will have a smooth surface finish and sharp details, making it ideal for marketing photos, investor presentations, or final design reviews. Because of SLA's high accuracy, it's also perfect for testing the fit of tight-tolerance assemblies.

Functional Testing and Production with SLS: If the part needs to serve a functional purpose and withstand mechanical stress, the final pre-production prototype or the first small-batch production run should be made with SLS. Using a material like Nylon PA12, these parts will be strong, durable, and ready for real-world testing. Thanks to the support-free nature of SLS, you can produce complex assemblies with moving parts that were validated visually with SLA.

Combining Processes on a Single Part

This hybrid mindset isn't just for different stages of a project; it can even apply to a single complex component. For instance, hybrid manufacturing combines additive processes (like 3D printing) with subtractive processes (like CNC machining) to get the best of both worlds.

- A complex metal part could be 3D printed using Direct Metal Laser Sintering (DMLS) to achieve an intricate internal lattice structure that is impossible to machine.

- After printing, the part can be moved to a CNC mill where critical mating surfaces, threads, and holes are machined to achieve tolerances that 3D printing alone cannot meet.

By partnering with a versatile supplier who offers multiple technologies under one roof, you can streamline this entire process. They can advise you on the most efficient path from initial concept to finished part, ensuring you aren't overpaying for high-end technology when a cheaper method would suffice, or sacrificing quality when precision is truly needed.

Conclusion

The decision between FDM, SLA, and SLS ultimately hinges on your project's specific requirements regarding detail, strength, surface finish, and budget. By carefully evaluating these factors, you can effectively choose the right 3D printing technology and, by extension, the best 3D printing SLA parts supplier to meet your needs. FDM offers unparalleled value for early-stage, low-cost prototyping, while SLA delivers superior aesthetics and precision for visual models. For durable, complex, and functional components, SLS stands out as the industrial-grade choice.

Understanding the strengths and weaknesses of each 3D printing method empowers you to make strategic choices that will optimize your manufacturing process, reduce costs, and deliver high-quality results. Whether you prioritize precision, durability, or affordability, an informed choice ensures a successful partnership with your supplier. By leveraging a hybrid approach—using the right technology for the right stage of development—you can accelerate your time to market while ensuring the highest quality for your final parts.

For companies seeking a professional and reliable manufacturing partner, SOMI Custom Parts is a leading 3D Printing SLA Parts Manufacturer, 3D Printing SLS Parts Manufacturer, and 3D Printing SLM Parts Manufacturer in China. We specialize in providing global OEM custom services, leveraging our expertise across a wide range of additive technologies to deliver parts that meet the most demanding specifications. Partner with us to turn your innovative designs into reality with precision, quality, and efficiency.