How CNC Milling and Turning Achieve Tight Tolerances for Machining Parts Manufacturers

As a CNC Machining Parts Manufacturer, we understand the critical role of precision in creating high-quality components. Modern manufacturing relies heavily on CNC machining, especially CNC turning and milling, to produce parts with extremely tight tolerances. This blog post will explore how these advanced techniques enable us to achieve such precision and why it's essential for various industries.

CNC machining has revolutionized manufacturing by offering unparalleled accuracy and automation. We, as a leading CNC Machining Parts Manufacturer, leverage the power of Computer Numerical Control to transform raw materials into intricate parts that meet the most demanding specifications. Join us as we delve into the world of CNC turning and milling and uncover how they contribute to manufacturing excellence.

The Fundamentals of CNC Turning for a CNC Machining Parts Manufacturer

CNC turning is a cornerstone of modern manufacturing, prized for its ability to produce cylindrical parts with exceptional accuracy and efficiency. For any CNC Machining Parts Manufacturer, mastering this process is essential for delivering components that meet the stringent requirements of industries ranging from aerospace to medical. This section breaks down the fundamental aspects of CNC turning, from the core process to the intricate machine components and the methods used to achieve unparalleled precision.

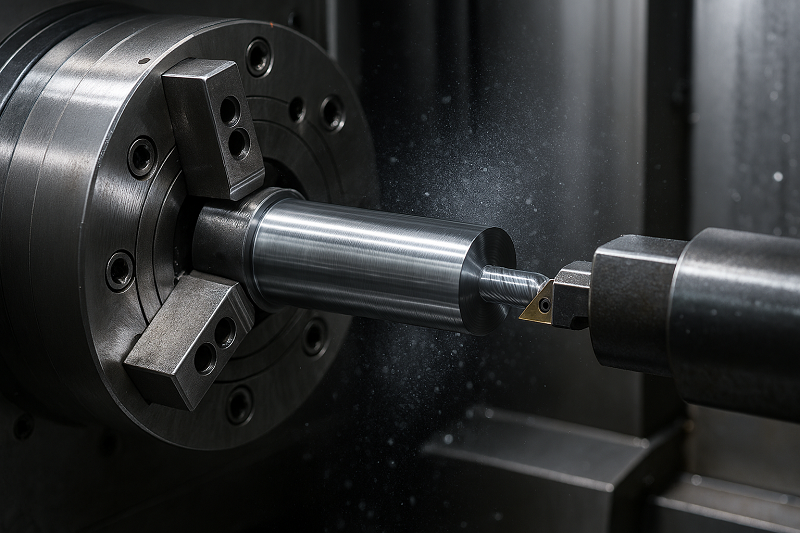

What is CNC Turning?

CNC (Computer Numerical Control) turning is a subtractive manufacturing process where a block of material, known as a workpiece, is held in a chuck and rotated at high speed. A stationary cutting tool is then moved along the rotating workpiece to remove material and shape it into the desired form. This process is conducted on a machine called a CNC lathe or turning center. The essence of CNC turning lies in the precise, computer-controlled movement of the cutting tool, which allows for the creation of complex external and internal geometries, such as cylinders, cones, threads, and grooves, with high repeatability.

The process begins with a 2D or 3D CAD (Computer-Aided Design) model of the final part. This digital design is then converted into a set of instructions, typically in a language called G-code, using CAM (Computer-Aided Manufacturing) software. The G-code dictates every movement of the cutting tool, including its path, speed, and feed rate, ensuring that each part is machined exactly to specification. While primarily used for cylindrical shapes, CNC turning can also be applied to square or hexagonal raw materials.

Common CNC turning operations include:

- Turning: Reducing the outer diameter of the workpiece. This can be straight, creating a uniform cylinder, or tapered, creating a cone shape.

- Facing: Creating a flat, smooth surface on the end of the workpiece, perpendicular to its rotational axis.

- Grooving: Cutting a narrow channel into the workpiece, often for O-rings or other functional features.

- Threading: Machining external or internal threads with precise pitch and depth.

- Drilling and Boring: Creating or enlarging a hole along the central axis of the workpiece.

Key Components of a CNC Lathe

The remarkable precision of a CNC turning center is a direct result of its sophisticated and robust components working in harmony. As a CNC Machining Parts Manufacturer, our ability to produce high-quality parts depends on the capabilities of these machines. Understanding each component reveals how a CNC lathe consistently achieves tight tolerances.

Here is a breakdown of the key components of a typical CNC lathe:

| Component | Function | Importance for Precision |

|---|---|---|

| Machine Bed | The foundational base of the lathe, typically made of heavy cast iron or polymer concrete. | Provides stability and vibration damping, preventing micro-movements that could affect accuracy. A rigid bed ensures all other components remain perfectly aligned. |

| Headstock | Houses the main spindle, the drive motor, and gear mechanisms. | The headstock's quality determines the spindle's rotational accuracy. Precision bearings and thermal stability are critical for preventing rotational errors. |

| Spindle | The component that holds and rotates the workpiece at high speeds. | A high-quality spindle ensures smooth rotation without runout (wobble), which is fundamental for creating perfectly cylindrical and concentric features. |

| Chuck | A specialized clamp mounted on the spindle that securely grips the workpiece. | Provides a firm, centered grip on the material. Any slight movement or misalignment in the chuck will directly translate into machining inaccuracies. |

| Tailstock | A movable component that supports the opposite end of a long workpiece. | Prevents deflection or "whipping" of long, slender parts during machining, ensuring uniform diameter along the entire length. |

| Turret | A rotating disk that holds a variety of cutting tools. | The turret allows for automated, rapid tool changes. Its indexing accuracy is crucial for operations requiring multiple tools, ensuring each tool is positioned correctly. |

| Carriage & Cross-Slide | Assemblies that move the cutting tool along the Z-axis (lengthwise) and X-axis (crosswise). | These are driven by high-precision ball screws and servo motors, allowing for tool movements with micron-level accuracy. |

| CNC Control Panel | The "brain" of the machine, where the G-code program is loaded and executed. | This computer system interprets the code and sends precise electrical signals to the drive motors, controlling every aspect of the machining process. |

Each of these components, from the massive machine bed to the tiny sensors in the feedback system, plays an indispensable role. For a CNC Machining Parts Manufacturer, the quality, calibration, and maintenance of these parts are non-negotiable for achieving the high-precision results our clients demand.

How CNC Turning Achieves Precision

Achieving tight tolerances in CNC turning is not accidental; it is the result of a synergy between advanced technology, robust mechanical design, and meticulous process control. A CNC Machining Parts Manufacturer leverages these factors to produce parts that are dimensionally accurate to within thousandths, or even ten-thousandths, of an inch.

Here are the primary factors that contribute to the high precision of CNC turning:

Computer Numerical Control (CNC): The core of precision lies in the "CNC" itself. By translating a digital design into machine commands (G-code), human error is virtually eliminated from the cutting process. The controller executes these commands with flawless repeatability, ensuring that every part in a production run is identical to the first.

High-Resolution Feedback Systems: Modern CNC lathes use closed-loop feedback systems. Encoders and sensors on the servo motors continuously monitor the exact position and speed of the cutting tool and axes. This data is sent back to the CNC controller in real-time, which then makes micro-adjustments to correct any deviation from the programmed path, ensuring extreme positional accuracy.

Rigid Machine Construction: The physical structure of a CNC lathe is built for stability. The machine bed is made from heavy, vibration-damping materials like cast iron to absorb the forces generated during cutting. This rigidity prevents any deflection or vibration that could mar the surface finish or compromise dimensional accuracy.

Precision Ball Screws and Linear Guides: The movement of the carriage and cross-slide is facilitated by high-precision ball screws and linear guides. These components convert the rotary motion of the servo motors into smooth, backlash-free linear motion. This ensures that the tool's movement is direct and precise, without the "slop" that can be found in less advanced machines.

Thermal Stability Management: Heat generated by the spindle motor and the cutting process can cause thermal expansion in machine components and the workpiece, leading to inaccuracies. Advanced CNC turning centers incorporate cooling systems for the spindle and use coolant to flood the cutting zone. This helps maintain a stable operating temperature, minimizing thermal drift and ensuring dimensional consistency over long production runs.

High-Quality Cutting Tools and Tooling: The cutting tool itself is a critical variable. Tools made from advanced materials like carbide and featuring specialized coatings can maintain a sharp cutting edge for longer, even when machining hard materials. A sharp, stable tool produces a cleaner cut and a better surface finish, which is often a key aspect of precision.

In-Process Measurement: Some advanced CNC lathes are equipped with probes that can automatically measure the workpiece during the machining cycle. The machine can then use this data to automatically adjust for tool wear or other small variations, ensuring the final dimensions are perfectly within tolerance.

By combining these technological and mechanical elements, a CNC Machining Parts Manufacturer can confidently produce complex parts that meet the most demanding precision requirements, making CNC turning an indispensable process in modern manufacturing.

The Power of CNC Milling for a CNC Machining Parts Manufacturer

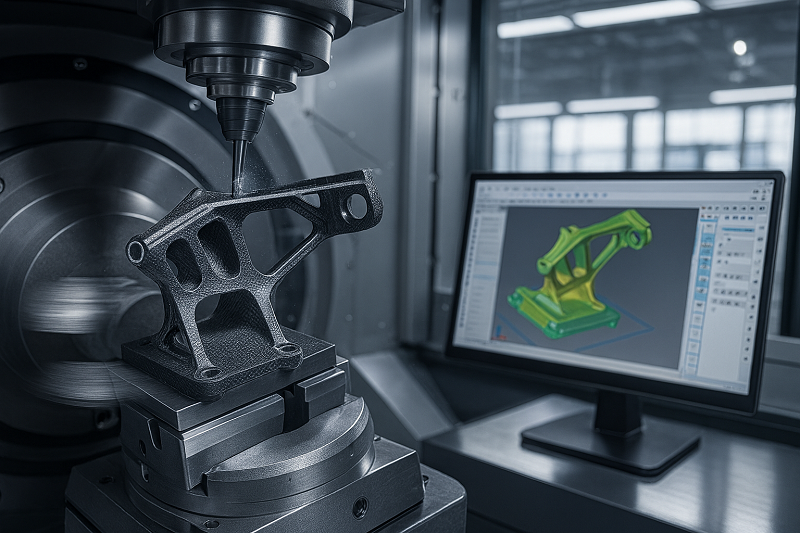

While CNC turning excels at creating cylindrical parts, CNC milling is the workhorse for producing complex, non-symmetrical components. For a comprehensive CNC Machining Parts Manufacturer, milling is an indispensable capability. It involves using a rotating multi-point cutting tool to remove material from a stationary workpiece. This process unlocks the ability to create a vast array of shapes, including flat surfaces, deep pockets, intricate contours, and complex 3D forms.

Understanding CNC Milling

At its core, CNC milling is a subtractive manufacturing process where a computer-controlled machine uses a rotating cylindrical cutting tool to shape a solid block of material. Unlike CNC turning, where the workpiece rotates, in milling the workpiece is held stationary on a machine bed while the cutting tool spins at high speed and moves along multiple axes to remove material.

The process starts with a 3D CAD model, which is then translated into G-code by CAM software. This code directs the milling machine's every move, controlling the tool's path, rotational speed, and feed rate with exceptional precision. This automation allows a CNC Machining Parts Manufacturer to produce highly detailed and accurate parts consistently, with tolerances as tight as +/- 0.0005 inches in some cases.

CNC milling is incredibly versatile and can perform a wide range of operations, including:

- Face Milling: Creating a large, flat surface on the top of the workpiece.

- Plain Milling: Machining flat surfaces parallel to the axis of the cutting tool.

- Drilling, Boring, and Tapping: Creating and threading holes of various sizes.

- Pocketing: Machining out an internal cavity or "pocket" within the workpiece.

- Contouring: Using the side of the cutting tool to create complex 2D or 3D curved surfaces.

- Slotting: Cutting narrow channels or slots into the part.

The Evolution of CNC Milling

The journey from manual milling to the highly automated CNC milling of today is a story of technological revolution. Understanding this evolution highlights the immense leap in precision and capability that modern manufacturing now commands.

Manual Machining: Before automation, skilled machinists operated manual milling machines. They controlled the tool's movement by turning handwheels, relying on their experience, skill, and mechanical scales to achieve accuracy. This process was labor-intensive, slow, and highly dependent on operator skill, making true interchangeability of parts a significant challenge.

Numerical Control (NC) - The 1940s & 1950s: The concept of automated machine control began with John T. Parsons in the late 1940s, who was working on a project to produce helicopter rotor blades. His work led to the development of the first Numerical Control (NC) machines in collaboration with MIT. These early machines were controlled by instructions fed through "punched tape," a long strip of paper with holes that dictated the machine's movements. While a revolutionary step, punched tape systems were cumbersome, prone to wear, and difficult to edit.

The Dawn of CNC - The 1960s & 1970s: The major breakthrough came with the integration of computers. The term "CNC" (Computer Numerical Control) emerged as computers replaced the physical punched tapes. This allowed programs to be stored in digital memory, edited easily, and executed repeatedly with perfect fidelity. The first CNC milling machine was introduced in 1967, and the development of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software in the 1970s further revolutionized the process. Now, complex toolpaths could be generated directly from a digital design.

Modern Era - The 1980s to Present: From the 1980s onwards, CNC technology has advanced at a rapid pace. The introduction of microprocessors made machines more powerful and affordable. The development of graphical user interfaces simplified operation. Most significantly, the evolution from basic 3-axis machines to multi-axis (4- and 5-axis) technology has opened the door to manufacturing parts of almost unimaginable complexity. Today, as a CNC Machining Parts Manufacturer, we operate in an era of digital connectivity, where machines can be networked, monitored remotely, and optimized using real-time data, representing the pinnacle of this century-long evolution.

Multi-Axis Machining: Expanding Capabilities

The term "axis" in CNC milling refers to a direction of movement for either the tool or the workpiece. The evolution from 3-axis to 4-axis and 5-axis machining represents a monumental leap in manufacturing capability, allowing for the creation of parts with increasingly complex geometries in a single setup. This is a key differentiator for an advanced CNC Machining Parts Manufacturer.

3-Axis Milling: This is the most common form of CNC milling. The cutting tool can move along three linear axes: X (left-right), Y (front-back), and Z (up-down). It is excellent for parts with features on a single plane, such as drilling holes, cutting slots, and machining profiles. However, for parts with angled features or features on multiple faces, the workpiece must be manually re-oriented and clamped for each new face, a process known as multiple setups.

4-Axis Milling: 4-axis milling adds a rotational axis (the A-axis) to the standard three linear axes. This axis typically involves the rotation of the workpiece itself around the X-axis. This allows for machining on four sides of a part in a single setup. It is particularly useful for creating features on cylindrical parts or for drilling holes on the side of a block. By eliminating the need for repositioning, 4-axis machining improves accuracy (as setup errors are reduced) and speeds up production time.

5-Axis Milling: This is the pinnacle of modern milling technology. 5-axis machining includes the three linear axes (X, Y, Z) plus two rotational axes (typically the A-axis and C-axis, or B-axis and C-axis). These additional axes allow the cutting tool to approach the workpiece from virtually any angle. This capability provides several transformative advantages:

- Machining of Extremely Complex Geometries: 5-axis machines can produce parts with compound curves, deep undercuts, and intricate 3D surfaces—like turbine blades or medical implants—that are impossible to create on 3-axis machines.

- Single-Setup Machining (Done-in-One): The greatest advantage is the ability to machine all five faces of a complex part in a single clamping. This drastically reduces setup time and eliminates the risk of alignment errors that can occur each time a part is manually repositioned.

- Improved Tool Life and Surface Finish: The machine can continuously orient the tool to maintain an optimal cutting position relative to the part surface. This allows for the use of shorter, more rigid cutting tools that are less prone to vibration, resulting in a superior surface finish and longer tool life.

- Greater Efficiency: By combining multiple operations into one, cycle times are significantly reduced, leading to faster lead times and lower costs for complex components.

The table below summarizes the key differences:

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling |

|---|---|---|---|

| Axes of Movement | X, Y, Z | X, Y, Z + A (rotation) | X, Y, Z + A & C or B & C (rotations) |

| Part Complexity | Simple, prismatic parts | Parts with features on up to 4 sides | Highly complex, organic, and multi-faceted parts |

| Setups Required | Multiple for complex parts | Fewer; can machine 4 sides in one setup | Often just one setup ("done-in-one") |

| Accuracy | Good, but error can accumulate with multiple setups | Very good; reduces setup-related errors | Excellent; highest accuracy due to minimal setups |

| Surface Finish | Good | Better | Superior, as tool angle is optimized |

| Ideal Applications | Flat plates, brackets, simple enclosures | Cams, gears, parts with side holes | Turbine blades, impellers, medical implants, complex molds |

For a CNC Machining Parts Manufacturer, investing in multi-axis technology is an investment in versatility, precision, and efficiency, enabling us to tackle the most challenging manufacturing projects with confidence.

Achieving Tight Tolerances: A Core Competency for Every CNC Machining Parts Manufacturer

For any serious CNC Machining Parts Manufacturer, the ability to achieve and consistently hold tight tolerances is not just a service—it's a core competency that defines their value. Tolerances are the foundation of precision engineering, ensuring that every component functions as intended. In a world where mechanical and electronic systems are becoming increasingly complex and compact, the margin for error is shrinking, making expertise in tight tolerance machining more critical than ever.

The Meaning of Tight Tolerances in Manufacturing

In manufacturing, "tolerance" refers to the permissible limit of variation in a physical dimension of a part. No manufacturing process can create a part to an exact, perfect measurement every time; there will always be some minuscule deviation. A tolerance specifies an acceptable range for this deviation. For example, a shaft designed to be 10.000 mm in diameter might have a tolerance of ±0.05 mm, meaning any shaft with a diameter between 9.95 mm and 10.05 mm is acceptable.

Tight tolerance machining, also known as precision or high-tolerance machining, refers to processes where this acceptable range of variation is extremely small. While a standard machining tolerance might be around ±0.1 mm (±0.004"), a tight tolerance is generally considered to be anything below that, often in the range of ±0.025 mm (±0.001") down to an incredible ±0.005 mm (±0.0002") or even finer for ultra-precise applications. To put this in perspective, a human hair is about 0.07 mm thick, so tight tolerance machining often deals with variations that are invisible to the naked eye.

The level of tolerance required is dictated by the part's function. Not every dimension on a part needs the tightest possible tolerance. A skilled CNC Machining Parts Manufacturer works with clients to identify critical dimensions—those that affect fit, form, or function—and applies tight tolerances there, while allowing for more standard tolerances on non-critical features to manage costs effectively.

Here is a general guide to understanding tolerance levels:

| Tolerance Range (Bilateral) | Classification | Typical Applications |

|---|---|---|

| ±0.25 mm (±0.010") | Standard | General fabrication, non-interfacing parts |

| ±0.13 mm (±0.005") | Standard/Fine | Parts with basic fit requirements |

| ±0.05 mm (±0.002") | Tight | Interfacing parts in machinery, automotive components |

| ±0.025 mm (±0.001") | Very Tight | Aerospace components, precision instruments, medical devices |

| < ±0.01 mm (< ±0.0004") | Ultra-Precision | High-performance engine parts, optical instruments, medical implants |

Achieving these tight tolerances requires advanced machinery, precise control over the manufacturing environment, sophisticated measurement tools, and deep expertise in machining processes.

The Impact of Precision on Product Performance

The precision afforded by tight tolerance machining has a profound and direct impact on the final product's performance, reliability, and lifespan. For a CNC Machining Parts Manufacturer, delivering this precision is about ensuring the end product works flawlessly.

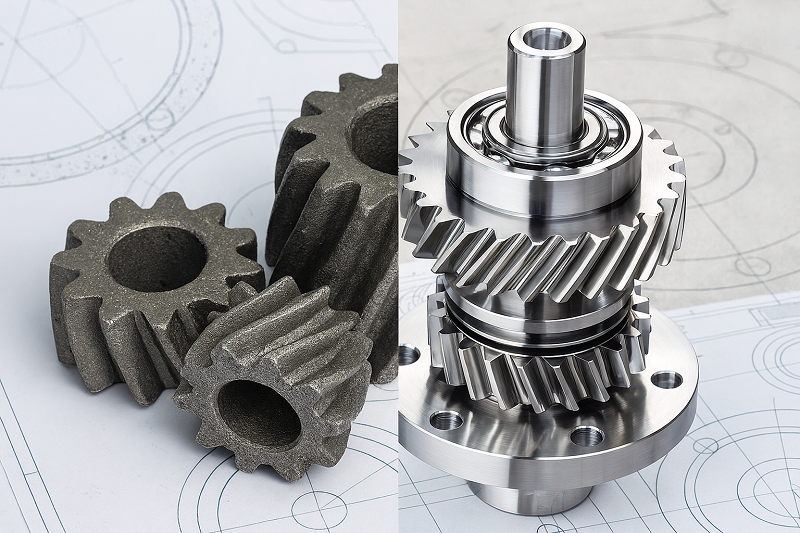

Improved Fit and Assembly: In any mechanical assembly, from a simple gearbox to a complex jet engine, components must fit together perfectly. Tight tolerances ensure that shafts fit smoothly into bearings, gears mesh without play or binding, and seals create a perfect barrier. This "snug fit" reduces the risk of errors during assembly, making the process faster and more reliable. In a 2023 article, it was noted that this level of accuracy helps reduce errors during assembly since each part fits snugly into place without needing modifications.

Enhanced Efficiency and Reduced Wear: Parts that fit together precisely operate with less friction, vibration, and energy loss. In a high-speed motor, for example, a perfectly balanced and aligned rotor made with tight tolerances will run more smoothly, convert more electrical energy into motion, and generate less heat. Over time, this reduces wear and tear on all related components, significantly extending the operational life of the entire assembly.

Guaranteed Reliability and Safety: In critical industries like aerospace, medical, and defense, component failure is not an option. Tight tolerances are essential for ensuring that parts perform predictably and reliably under extreme conditions. For an aircraft landing gear component or a surgical robot arm, even a microscopic deviation can compromise safety and lead to catastrophic failure. Precision machining ensures that every part meets the exacting standards required for these high-stakes applications.

Consistency Across Production Runs: CNC machining's ability to hold tight tolerances allows for high repeatability from one part to the next, even in large production volumes. This consistency is crucial for creating interchangeable parts, which simplifies maintenance, repairs, and supply chain management. If one component in a machine fails, it can be replaced with an identical one, confident that it will fit and function perfectly.

Ultimately, precision is not just about making a part look good; it's about guaranteeing its functional integrity. As a CNC Machining Parts Manufacturer, our commitment to tight tolerances is a commitment to delivering products that are safer, more reliable, and perform at a higher level.

Minimizing Waste and Optimizing Costs

At first glance, it might seem that striving for tighter tolerances would increase costs due to the need for more advanced machinery and longer cycle times. While this can be true for the machining process itself, precision manufacturing ultimately leads to significant cost savings and waste reduction across the entire product lifecycle.

Reduction of Material Scrap and Rework: High-precision CNC machining gets the part right the first time. By adhering strictly to the digital design and using automated feedback systems, the process drastically reduces the number of parts that fall outside of specification. This minimizes the amount of material that ends up as scrap and eliminates the costly and time-consuming process of reworking or completely remanufacturing faulty components.

Efficient Material Usage: Modern CAM software can optimize toolpaths to remove material in the most efficient way possible, a practice known as "near-net-shape" production. This minimizes the amount of raw material used for each part. Furthermore, the precision of CNC machining allows designers to create parts that are strong yet lightweight, using material only where it is functionally necessary. This not only saves material but can also reduce the weight of the final product, a critical factor in industries like automotive and aerospace.

Faster and More Efficient Assembly: When every component is machined to precise tolerances, assembly becomes a smooth and predictable process. Workers don't waste time trying to fit ill-fitting parts together, and the need for manual adjustments like filing or shimming is eliminated. This reduction in assembly time translates directly to lower labor costs and higher production throughput.

Lower Lifetime and Warranty Costs: Parts made with high precision are more reliable and last longer. This reduces the frequency of product failures, leading to fewer warranty claims, repairs, and customer complaints. For a manufacturer, this means a better brand reputation and lower long-term service costs.

Sustainable Manufacturing: Reducing waste is a key pillar of sustainable manufacturing. By using less material, consuming less energy due to efficient processes, and creating longer-lasting products, CNC machining helps minimize the environmental footprint of manufacturing. Companies are also increasingly recycling scrap material, such as metal shavings, to promote a circular economy.

While there is an initial investment in the technology and expertise required for tight tolerance machining, the downstream benefits are undeniable. As a CNC Machining Parts Manufacturer, we view precision not as a cost center, but as a long-term investment in quality, efficiency, and sustainability.

The Role of Advanced Software and Tools

Achieving tight tolerances is impossible without the seamless integration of advanced software and cutting-edge physical tools. These technologies are the enablers that translate a designer's intent into a physical part with micron-level accuracy. For a CNC Machining Parts Manufacturer, expertise in wielding these tools is as important as the machines themselves.

1. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) Software: The process begins with CAD software, which is used to create a detailed 2D or 3D digital model of the part. This is more than just a drawing; it is a precise virtual representation containing all dimensional and tolerance information.

Once the design is finalized, it's imported into CAM software. CAM is the bridge between the digital model and the physical machine. It plays a crucial role in precision by:

- Generating Optimal Toolpaths: CAM software calculates the most efficient and precise path for the cutting tool to follow. It can create complex toolpaths for 5-axis machining that would be impossible to program manually.

- Simulation and Verification: Before any material is cut, CAM software can run a complete virtual simulation of the machining process. This allows machinists to detect potential collisions between the tool, workpiece, and fixtures, and to verify that the final part will match the design. This pre-production verification prevents costly errors and material waste.

- Process Optimization: The software helps in selecting the ideal cutting speeds, feed rates, and depth of cut for a given material and tool, ensuring a high-quality surface finish and preventing undue stress on the tool or part.

2. High-Performance Cutting Tools: The cutting tool is where the "rubber meets the road." No amount of software or machine precision can compensate for a poor-quality or worn-out tool. Achieving tight tolerances requires:

- Advanced Materials: Tools are often made from solid carbide or have inserts made from specialized materials like cubic boron nitride (CBN) or polycrystalline diamond (PCD). These materials are extremely hard and wear-resistant, allowing them to maintain a sharp cutting edge for much longer.

- Specialized Coatings: Modern cutting tools are often coated with thin, super-hard layers of materials like Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN). These coatings reduce friction, improve chip evacuation, and protect the tool from heat and wear, leading to a cleaner cut and better surface finish.

- Precision Tool Holders: The tool holder, which connects the cutting tool to the machine's spindle, must be perfectly balanced and have minimal runout (wobble). High-precision tool holders ensure that the tip of the tool rotates exactly on the spindle's centerline, which is critical for dimensional accuracy.

3. Advanced Workholding and Fixturing: The workpiece must be held absolutely stationary and in a precise location during the milling process. Any movement, however small, will result in inaccuracies. Advanced workholding solutions, such as hydraulic or pneumatic vises and custom-built fixtures, provide the rigid clamping force needed to withstand the high forces of machining without deforming the part itself. For complex parts, vacuum chucks or specialized multi-axis fixtures are used.

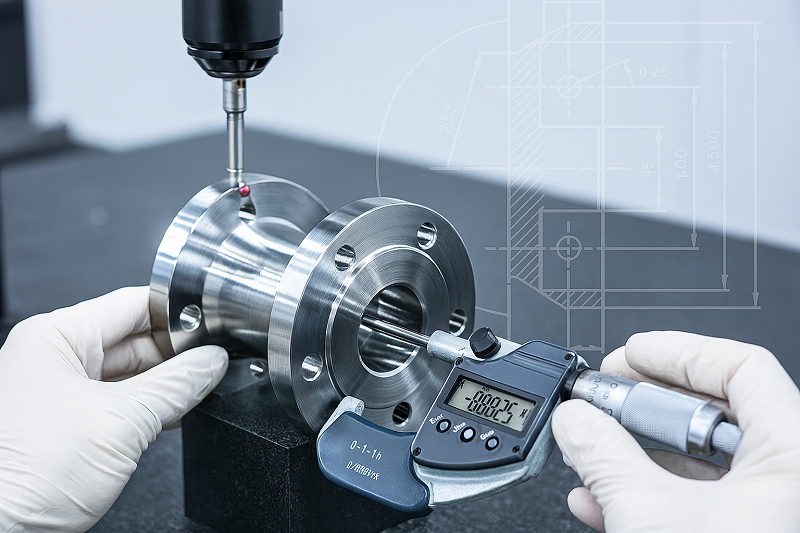

4. Metrology and Inspection Equipment: Finally, you cannot make what you cannot measure. A CNC Machining Parts Manufacturer must have a robust quality control process equipped with advanced metrology tools to verify that tolerances have been met. This includes:

- Coordinate Measuring Machines (CMMs): These are highly precise devices that use a probe to measure the geometry of a part in 3D space, providing a detailed report comparing the physical part to its CAD model.

- Optical Comparators and Vision Systems: These use magnification and cameras to inspect profiles and measure features that are difficult to access with touch probes.

- Laser Scanners: For complex surfaces, laser scanners can capture millions of data points to create a precise digital twin of the finished part for inspection.

By combining the digital intelligence of CAD/CAM software with the physical precision of advanced tooling and inspection, a CNC Machining Parts Manufacturer can create a controlled, repeatable process capable of achieving the tightest tolerances demanded by modern industry.

Quality Control and Optimization in Precision CNC Machining for a CNC Machining Parts Manufacturer

Producing parts with tight tolerances is only half the battle; verifying that those tolerances have been met is equally, if not more, important. For a CNC Machining Parts Manufacturer, a robust quality control (QC) and process optimization strategy is the backbone of its commitment to precision. It is a systematic approach that ensures every component leaving the facility is a perfect match to the client's specifications. This involves a multi-stage inspection process, state-of-the-art measurement tools, and a culture of continuous improvement.

A comprehensive quality control framework in CNC machining can be broken down into several key stages and practices:

1. Pre-Production Inspection and Planning: Quality starts before the machine is even turned on.

- Raw Material Inspection: Every batch of raw material is inspected upon arrival to ensure it meets the required standards for composition, hardness, and dimensional accuracy. Inconsistent material can lead to unpredictable machining behavior and defects.

- Design for Manufacturability (DFM) Review: A thorough review of the CAD model is conducted to ensure the design is manufacturable and that the specified tolerances are achievable.

- Program Verification: The G-code program is simulated and verified to catch any programming errors that could lead to a crash or an out-of-spec part.

2. In-Process Inspection and Monitoring: Catching deviations during the machining process is far more efficient than finding them in a finished part.

- First Article Inspection (FAI): The very first part produced in a new setup is subjected to a complete and rigorous inspection. This verifies that the machine setup, tooling, and program are all correct before commencing a full production run.

- On-Machine Probing: Many modern CNC machines are equipped with touch probes that can automatically perform measurements during the machining cycle. These probes can be used to set work offsets precisely, measure features as they are cut, detect tool wear or breakage, and make real-time adjustments to maintain accuracy. This allows the machine to self-correct for minor deviations, ensuring consistency throughout a long run.

- Statistical Process Control (SPC): For high-volume production, SPC is a data-driven method used to monitor and control the process. By taking regular samples and plotting key measurements on control charts, operators can identify trends or variations that might indicate a developing problem—like tool wear or thermal drift—before it results in defective parts.

3. Post-Process Inspection and Validation: Once a part is complete, it undergoes a final, comprehensive inspection to validate its quality.

- Coordinate Measuring Machines (CMMs): The CMM is the gold standard for quality assurance in precision machining. It uses a highly sensitive probe to take precise 3D measurements of the part's geometry. This data is then compared directly against the original CAD model to verify that every dimension, feature, and geometric tolerance (like flatness, perpendicularity, and position) is within specification. CMMs eliminate human error from the measurement process and provide highly accurate, repeatable results.

- Traditional Metrology Tools: While CMMs are essential, traditional tools like digital calipers, micrometers, and height gauges are still used for quick checks and verification of less critical dimensions on the shop floor.

- Advanced Inspection Tools: For certain applications, other non-contact inspection methods may be used, including optical comparators, 2D and 3D laser scanners, and vision systems that can quickly measure complex profiles.

4. Machine Calibration and Maintenance: The precision of a CNC machine is not permanent. Over time, mechanical wear, vibrations, and thermal cycles can cause its components to fall slightly out of alignment, which directly impacts its ability to hold tight tolerances.

- Regular Calibration: It is essential to regularly calibrate the machine's axes, spindle, and positioning systems. Using tools like laser interferometers and ballbars, technicians can measure and compensate for any geometric errors in the machine's movement, restoring its accuracy to "like new" condition.

- Preventive Maintenance: A strict maintenance schedule—including routine cleaning, lubrication of moving parts, and inspection of components for wear—is crucial. Well-maintained equipment is more reliable, operates at peak performance, and is far less likely to produce unexpected errors.

By integrating these quality control and optimization practices into every step of the manufacturing process, a CNC Machining Parts Manufacturer can move beyond simply making parts to engineering precision. This systematic approach ensures reliability, reduces waste, and builds the trust that is foundational to long-term partnerships with clients in demanding industries.

Applications and Advantages of Precision CNC Machining across Industries for a CNC Machining Parts Manufacturer

The ability of CNC turning and milling to produce parts with exceptional accuracy and repeatability has made them indispensable across a wide spectrum of industries. For a CNC Machining Parts Manufacturer, this versatility opens up opportunities to serve sectors where performance, safety, and reliability are non-negotiable. From the cars we drive to the medical devices that save lives, precision-machined components are the invisible backbone of modern technology.

Transforming the Automotive Sector

The automotive industry is a high-volume, high-stakes environment where efficiency and reliability are paramount. CNC machining is extensively used to manufacture critical components that must withstand significant stress and perform flawlessly for years.

- Engine Components: The heart of a vehicle, the engine, is a complex assembly of precision parts. CNC machining is used to produce components like pistons, cylinder heads, engine blocks, crankshafts, and camshafts with the tight tolerances needed to reduce friction, improve fuel efficiency, and ensure a long operational life.

- Transmission and Drivetrain Parts: Components such as gears, shafts, and transmission housings require intricate geometries and high strength. CNC turning and milling ensure that these parts mesh perfectly and transfer power smoothly, contributing to a better driving experience and enhanced durability.

- Brake and Suspension Systems: Safety-critical components like brake calipers, rotors, and suspension arms are manufactured using CNC machining to guarantee their strength and reliability under extreme loads and temperatures.

- Rapid Prototyping: Before mass production, automotive companies rely on CNC machining to quickly create accurate prototypes of new parts. This allows for rapid design validation and testing, significantly shortening the development cycle for new vehicles.

- Electric Vehicles (EVs): With the shift to electric mobility, CNC machining is crucial for producing components unique to EVs, such as lightweight battery enclosures, motor housings, and cooling plates, all of which require tight tolerances for thermal management and structural integrity.

Advancing Medical Device Manufacturing

In the medical field, there is no margin for error. The precision, consistency, and ability to work with biocompatible materials make CNC machining a vital technology for producing life-saving and life-enhancing devices.

- Surgical Instruments: Instruments used in surgery, especially for minimally invasive procedures, require complex shapes and extreme sharpness. CNC machining is used to create scalpels, forceps, retractors, and other tools with micron-level accuracy, ensuring they perform as intended and can withstand repeated sterilization cycles.

- Orthopedic Implants: Implants such as hip and knee replacements, spinal implants, and bone screws must have a perfect fit and a flawless surface finish to ensure biocompatibility and prevent patient discomfort or rejection. CNC machining, particularly 5-axis milling, is used to manufacture these complex, often patient-specific, implants from materials like titanium and PEEK.

- Medical Device Components: CNC machining is employed to create a vast range of components for medical equipment, including parts for pacemakers, insulin pumps, diagnostic machines (like MRI and CT scanners), and fluid delivery systems. Housings, connectors, and internal mechanisms all rely on the precision of CNC to function correctly.

- Custom Prosthetics: Using data from 3D scans, CNC machines can fabricate custom prosthetic limbs and orthotic devices that are perfectly tailored to a patient's unique anatomy, improving comfort and functionality. The ability of CNC manufacturing to support rapid prototyping is also a key advantage in developing and testing new medical device designs quickly.

Aerospace: Where Precision is Paramount

The aerospace industry operates under the most stringent standards of all, as component failure can have catastrophic consequences. Precision is not just a goal; it is a fundamental requirement for safety and performance. A CNC Machining Parts Manufacturer serving this sector must adhere to exacting quality standards like AS9100.

- Engine and Turbine Components: Jet engines operate under extreme temperatures and pressures. CNC machining is essential for creating complex parts like turbine blades, rotors, and housings from high-performance superalloys like Inconel and titanium. The aerodynamic surfaces of these components must be machined flawlessly to maximize efficiency and thrust.

- Structural Components (Airframe): The skeleton of an aircraft, including parts like fuselage frames, wing ribs and spars, and engine mounts, must be both incredibly strong and as lightweight as possible. 5-axis CNC machining allows for the creation of these large, monolithic parts with complex pockets and contours to reduce weight without compromising structural integrity.

- Landing Gear: As a critical system that bears enormous loads during takeoff and landing, landing gear components like struts and actuators are machined from high-strength steel and titanium alloys to ensure absolute reliability and durability.

- Avionics and Interior Components: CNC machining is also used to produce enclosures for sensitive electronic systems (avionics), which require tight fits to protect them from vibration and electromagnetic interference. Additionally, parts like seat frames and interior brackets are machined to balance strength with weight savings.

- Material Versatility: The aerospace industry utilizes a wide range of advanced materials, from lightweight aluminum and titanium alloys to high-strength composites like carbon fiber. CNC machining is one of the few processes capable of shaping these often difficult-to-machine materials to the required tight tolerances.

The ability to deliver unparalleled precision, work with advanced materials, and ensure complete part-to-part consistency makes CNC machining the cornerstone of modern aerospace manufacturing, enabling the creation of safer, more efficient, and more capable aircraft and spacecraft.

Conclusion

As a dedicated CNC Machining Parts Manufacturer, we are committed to delivering components that not only meet but exceed the highest standards of precision and quality. The integration of advanced CNC turning and milling enables us to tackle complex designs and produce parts with the tightest tolerances, ensuring optimal performance and reliability in diverse applications. From the foundational stability of a machine's bed to the micron-level adjustments of its control system, every element works in concert to transform raw material into a component engineered for perfection.

The journey of a component from a digital CAD file to a highly precise physical part is a testament to the sophistication and power of modern CNC machining. As a CNC Machining Parts Manufacturer, we understand that this is an ever-evolving field. We continuously invest in cutting-edge technology, from 5-axis machines to advanced metrology systems, and cultivate the deep expertise required to remain at the forefront. By doing so, we provide our clients with robust, accurate, and cost-effective solutions for their most demanding manufacturing needs, ensuring that from the depths of the ocean to the far reaches of space, our components perform flawlessly.