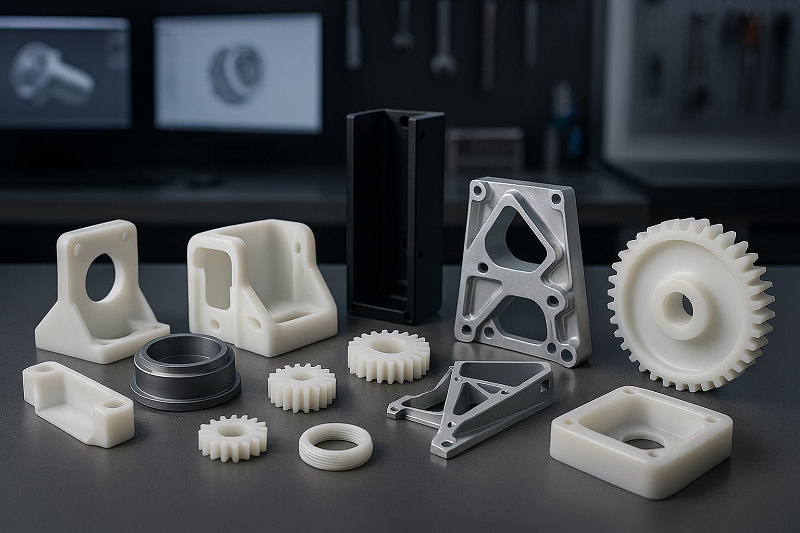

Custom Machined Plastic Parts: Understanding the Differences Between 3D Printing and CNC Machining

As product designers and engineers, we're constantly faced with a myriad of manufacturing choices when bringing custom machined plastic parts to life. Two primary contenders for prototyping and low-to-mid volume production are CNC machining and industrial-grade 3D printing. But how do we decide which is the optimal method for our specific needs?

Navigating the landscape of manufacturing technologies can be complex. This guide aims to clarify the distinctions between 3D printing and CNC machining, helping us understand their respective strengths and weaknesses when it comes to producing custom machined plastic parts.

Understanding the Fundamental Differences for Custom Machined Plastic Parts: Additive vs. Subtractive

At the core of the comparison between CNC machining and 3D printing are two fundamentally opposite approaches to manufacturing. CNC machining is a subtractive process, meaning it starts with a solid block of material and carves away unwanted sections to reveal the final part. In contrast, 3D printing is an additive process, building a part from the ground up, one layer at a time. This core difference influences everything from material choice and design complexity to cost and production speed.

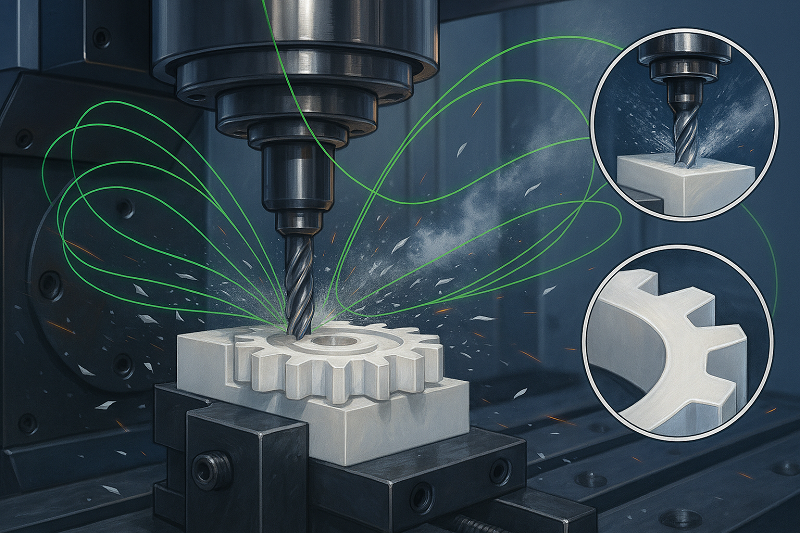

What is CNC Machining?

CNC (Computer Numerical Control) machining is a manufacturing process where computer software guides high-precision cutting tools to shape parts from a solid block or sheet of material. This method is renowned for its precision and ability to produce parts with extremely tight tolerances, making it a go-to for industries like aerospace, medical, and automotive where accuracy is paramount.

The Subtractive Nature and Process of CNC for Plastic Parts

The journey of a CNC machined plastic part begins with a digital design, typically a CAD (Computer-Aided Design) model. This model is then converted into a CAM (Computer-Aided Manufacturing) file that generates G-code, a set of instructions for the CNC machine. The process follows a clear, subtractive path:

- Material Preparation: A solid block of the chosen plastic is securely mounted onto the CNC machine's worktable.

- Tool Path Execution: The CNC machine, following the G-code, begins to remove material using various cutting tools like mills, drills, or lathes. The tool moves along multiple axes to carve out the precise geometry of the design.

- Part Finalization: Once the cutting is complete, the finished part is removed from the block. It may then undergo post-processing steps like polishing to achieve the desired surface finish.

This subtractive method ensures that the final part is a solid, homogenous piece with excellent structural integrity derived from the original material block.

Key Components and Functionality in CNC Machining

A CNC machine is a complex system of components working in concert to achieve precision. Key elements include:

- Machine Frame: Provides stability and resistance to vibrations, which is crucial for maintaining accuracy, especially with hard plastics.

- Controller: The "brain" of the machine, it interprets G-code and directs the motors and tools to execute the programmed movements.

- Spindle: This component holds and rotates the cutting tool. For plastics, high-speed spindles are often used to ensure clean cuts and prevent melting.

- Cutting Tools: These can include drills for creating holes, end mills for carving complex shapes, and lathes for producing round parts. The choice of tool is critical and depends on the plastic and desired geometry.

- Worktable and Fixturing: The surface where the plastic block is held in place, often using clamps or vacuum systems to ensure it doesn't move during the high-speed machining process.

- Motion System: A system of motors and guide rails that moves the spindle and/or the worktable along various axes (typically X, Y, and Z) to create the part's shape. Advanced machines can have 4 or 5 axes for more complex geometries.

What is 3D Printing?

3D printing, also known as additive manufacturing (AM), is a revolutionary process that creates three-dimensional objects directly from a digital file. Instead of removing material, it builds the object layer by layer, adding material only where it is needed until the final form is complete. This approach opens up a world of possibilities for creating highly complex and customized parts.

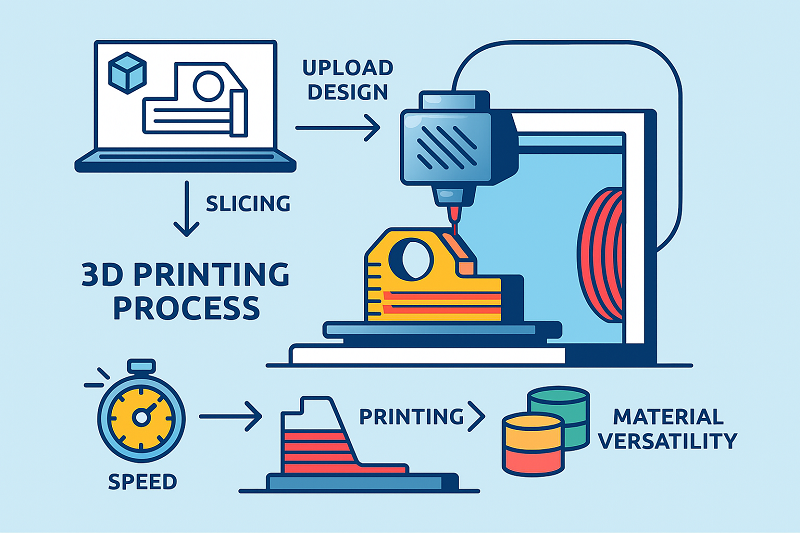

The Additive Nature and Layer-by-Layer Process of 3D Printing Plastic Parts

The 3D printing process also starts with a 3D CAD model. However, the subsequent steps are additive:

- Slicing the Model: Specialized software "slices" the CAD model into hundreds or thousands of thin, horizontal layers. This sliced file essentially creates a detailed, layer-by-layer blueprint for the printer.

- Building the Part: The 3D printer reads the sliced file and begins depositing, curing, or fusing the material one layer at a time, starting from the build platform and moving upwards.

- Layer Fusion: Each new layer bonds to the one beneath it, gradually building the solid object.

- Final Part: Once all layers are complete, the part is removed from the printer. It might require some post-processing, like removing support structures or surface treatments.

This layer-by-layer construction is what gives 3D printing its unique ability to produce intricate internal channels, complex geometries, and lightweight structures that are impossible with traditional manufacturing methods.

Diverse 3D Printing Technologies and Their Applications for Plastics

There isn't just one type of 3D printing. Several distinct technologies exist, each suited for different plastic materials and applications. The three most common for plastics are:

- Fused Deposition Modeling (FDM): This is the most widely recognized form of 3D printing, especially at the consumer level. FDM printers work by melting a thermoplastic filament and extruding it through a nozzle, depositing it layer by layer to build the part. It's excellent for basic proof-of-concept models and low-cost prototypes.

- Stereolithography (SLA): The world's first 3D printing technology, SLA uses an ultraviolet (UV) laser to selectively cure liquid photopolymer resin in a vat, hardening it layer by layer. SLA is known for producing parts with high accuracy, fine details, and a very smooth surface finish, making it ideal for detailed prototypes and functional parts.

- Selective Laser Sintering (SLS): This technology uses a high-powered laser to fuse or sinter small particles of polymer powder together. Because the unfused powder supports the part during the build, SLS can create very complex geometries without the need for dedicated support structures. It is a popular choice for durable, functional prototypes and end-use parts.

Other technologies like Digital Light Processing (DLP), which is similar to SLA but uses a projector screen to cure entire layers at once for faster speeds, and Multi Jet Fusion (MJF) are also expanding the capabilities of plastic additive manufacturing.

Evaluating Material Options and Properties for Custom Machined Plastic Parts

The choice of material is a critical decision that directly impacts the performance, durability, appearance, and cost of your custom plastic part. Both CNC machining and 3D printing offer a range of plastic options, but their compatibility and the resulting properties of the final part can differ significantly.

Material Versatility and Limitations in CNC Plastic Machining

One of the great strengths of CNC machining is its ability to work with a vast array of engineering-grade plastics. Since the process starts with a solid block of stock material, the machined part retains the full, inherent properties of that material. This means you can select plastics based on very specific performance requirements.

Common CNC Machinable Plastics Include:

- ABS (Acrylonitrile Butadiene Styrene): A cost-effective, easy-to-machine plastic with good impact resistance.

- Polycarbonate (PC): Offers excellent toughness, impact strength, and optical clarity.

- Nylon (PA): Known for its high durability, strength, and excellent abrasion resistance, making it great for dynamic parts like gears.

- POM (Acetal/Delrin): Valued for its high stiffness, dimensional stability, low friction, and excellent machinability, ideal for precision mechanical components.

- PEEK (Polyether Ether Ketone): A high-performance plastic that maintains its mechanical properties at extreme temperatures (up to 260°C) and has exceptional chemical resistance, though it is one of the more expensive options.

- Acrylic (PMMA): Chosen for its optical clarity, weather resistance, and high-quality surface finish.

- PVC (Polyvinyl Chloride): A versatile and durable plastic known for its chemical and flame resistance.

The primary limitation is that not all plastics are suitable for machining. Softer, more flexible materials can be difficult to cut accurately, and the heat generated during machining can cause some plastics with low melting points to deform or warp. A comprehensive understanding of SOMI CNC Machining Capability can help navigate these choices to optimize results.

Material Selection and Performance in 3D Printed Plastic Parts

3D printing materials have expanded rapidly, offering a diverse palette for creating plastic parts. However, the selection is generally more limited compared to CNC machining, and the chosen printing technology often dictates the compatible materials.

Key Material Families in 3D Printing:

- Thermoplastics (FDM): This is a broad category including popular filaments like PLA, ABS, and PETG.

- PLA (Polylactic Acid): Biodegradable and easy to print, it's a top choice for prototypes and models where high strength isn't critical.

- ABS (Acrylonitrile Butadiene Styrene): Offers better durability and heat resistance than PLA.

- PETG (Polyethylene Terephthalate Glycol): A good all-rounder, combining the ease of printing of PLA with the strength of ABS.

- Photopolymer Resins (SLA/DLP): These liquid resins cure into hard plastic when exposed to UV light. They are available in a wide variety of formulations, including standard, tough, flexible, and even "ABS-like" or "PP-like" to mimic the properties of traditional plastics. They are known for producing parts with high detail and a smooth finish.

- Polymer Powders (SLS): The most common material for SLS is nylon (PA11, PA12), which produces strong, durable, and functional parts with properties similar to injection-molded components. Flexible TPUs and other engineering-grade powders are also available.

The SOMI 3D Printing Capability showcases a range of these materials, suitable for applications from aesthetic models to functional end-use parts. One unique advantage of 3D printing is the ability to create parts from flexible, rubber-like materials like TPU (Thermoplastic Polyurethane), which are challenging to handle with CNC machining.

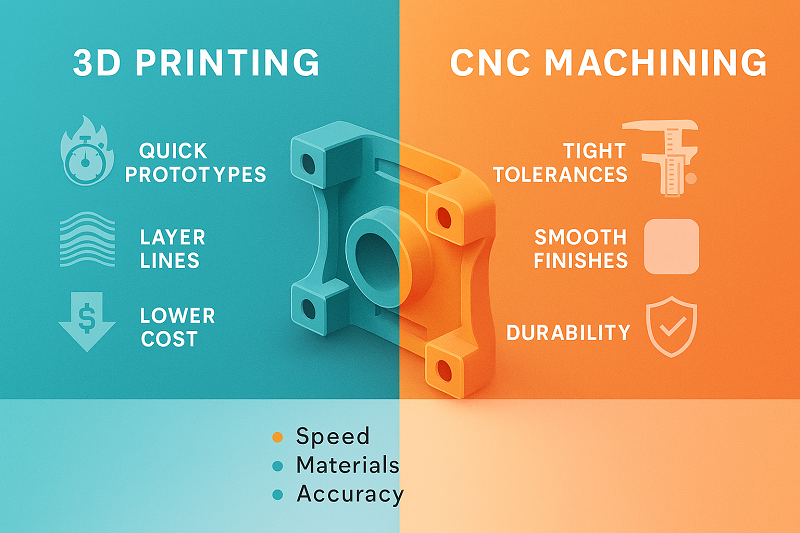

Achieving Desired Strength and Durability for Custom Machined Plastic Parts

When strength and durability are top priorities, the manufacturing process plays a crucial role.

-

CNC Machining: Parts machined from a solid block of plastic are isotropic, meaning their mechanical properties are consistent in all directions. This gives them superior strength, toughness, and resistance to impact compared to most 3D-printed counterparts. If a part needs to withstand significant mechanical stress or high impact, CNC machining is generally the more reliable choice. Components made with CNC machining can achieve significantly higher tensile strength—sometimes 40-60% more—than 3D-printed parts made from the same base material.

-

3D Printing: 3D-printed parts are created layer by layer, which can result in anisotropic properties. This means the part is typically weaker in the Z-axis (the direction of the build) because the bonds between layers are not as strong as the solid material itself. Under high stress or impact, a 3D-printed part may be more likely to delaminate or crack between these layers. However, advancements in materials and printing technologies, such as SLS with nylon, can produce parts with excellent mechanical properties that are suitable for many functional applications.

The table below offers a simplified comparison of expected strength for a part made from Nylon PA12 using different methods.

| Property | CNC Machined PA12 | 3D Printed PA12 (SLS/MJF) |

|---|---|---|

| Tensile Strength | 70-85 MPa | 48-55 MPa |

| Impact Strength | 150-180 J/m | 110-130 J/m |

| Structure | Isotropic (Uniform Strength) | Anisotropic (Strength varies by axis) |

(Data sourced from comparative industry studies).

Ultimately, for applications demanding the highest possible strength and long-term durability, CNC machining holds the edge. For applications where complex designs and rapid iteration are more critical, the strength offered by advanced 3D printing methods is often more than sufficient.

Comparing Geometric Capabilities and Design Flexibility for Custom Machined Plastic Parts

Design freedom is often a deciding factor when selecting a manufacturing process. While both CNC machining and 3D printing can create a wide range of custom plastic parts, their capabilities regarding geometric complexity, surface finish, and the need for post-processing are vastly different.

Design Constraints and Complexities in CNC Machining Plastic Parts

CNC machining is a powerhouse of precision, but its subtractive nature imposes certain design constraints. The primary limitation is tool access. The cutting tool must be able to physically reach every surface it needs to machine. This creates challenges for:

- Internal Geometries: It's difficult or impossible to create complex internal features, enclosed cavities, or undercuts that the tool cannot reach.

- Deep, Narrow Pockets: Machining very deep cavities with a small diameter is challenging because it requires long, thin tools that are prone to vibration and breaking.

- Sharp Internal Corners: Because cutting tools are cylindrical, they inherently leave a radius in any internal corner. Achieving a perfectly sharp 90-degree internal corner is not possible without secondary processes like EDM.

- Thin Walls: While possible, machining very thin walls can be risky as the plastic may vibrate, deform, or even break under the force of the cutting tool.

Despite these constraints, multi-axis CNC machines (4-axis and 5-axis) can rotate the workpiece and the tool head to access more complex angles, significantly expanding design possibilities compared to basic 3-axis machines.

Unleashing Design Freedom with 3D Printing for Intricate Plastic Parts

This is where 3D printing truly shines. Because it builds parts from the ground up, layer by layer, it can produce geometries that are simply impossible to achieve with subtractive methods. This unmatched design freedom allows for:

- Complex Internal Structures: Engineers can design parts with intricate internal channels for fluid flow, cooling, or lightweighting.

- Interlocking and Interwoven Parts: 3D printing can create pre-assembled mechanisms or chainmail-like structures in a single print.

- Organic and Complex Shapes: It is perfectly suited for creating organic, curved, and highly complex surfaces without any increase in manufacturing difficulty.

- Part Consolidation: Multiple components that would normally be assembled can be redesigned and printed as a single, more robust part, reducing assembly time and potential points of failure.

This capability makes 3D printing an invaluable tool for rapid prototyping, where designs are frequently iterated and tested, as well as for producing end-use parts with optimized performance and reduced weight.

Surface Finish and Post-Processing Considerations for Custom Machined Plastic Parts

The "out-of-the-box" surface finish of a part varies greatly between the two technologies and can influence the need for additional post-processing steps.

-

CNC Machining: CNC machining generally produces parts with a superior surface finish. The cutting process often leaves a smooth, clean surface with visible but very fine tool marks. If required, these parts can be easily polished, sandblasted, or vapor polished to achieve a near-mirror or perfectly uniform matte finish with minimal effort. This makes CNC ideal for aesthetic components or parts that require a very smooth surface for functional reasons (e.g., sealing).

-

3D Printing: The surface finish of 3D printed parts is dependent on the technology and layer height.

- FDM: Parts produced with FDM typically have visible layer lines, resulting in a ridged or stepped surface texture. Significant post-processing, such as sanding, filling, and painting, is often required to achieve a smooth finish.

- SLA: SLA parts have the smoothest surface finish of all plastic 3D printing technologies right out of the printer. While layer lines can still be present, they are often microscopic. Light sanding or a clear coat is usually all that is needed for a perfectly smooth, injection-mold-like surface.

- SLS: SLS parts have a grainy or slightly porous matte surface finish due to the nature of the sintered powder. They can be bead-blasted for a more uniform finish or dyed for color.

In summary, if a pristine surface finish is a critical requirement with minimal post-processing, CNC machining is often the more direct route. However, with the right technology (like SLA) and finishing techniques, 3D printed parts can also achieve very high-quality surfaces.

Cost, Speed, and Production Volume: Key Factors for Custom Machined Plastic Parts

Beyond technical specifications, business considerations like cost, speed, and scalability are crucial in deciding between CNC machining and 3D printing. The optimal choice often depends on the project's stage—from a single prototype to full-scale production.

Analyzing Cost Structures for Low to High Volume Custom Machined Plastic Parts

The cost-effectiveness of each technology is heavily dependent on the number of parts being produced.

-

3D Printing: This method has very low setup costs. Once a digital model is ready, the printing process can begin almost immediately. This makes it extremely cost-effective for producing a single part or a very small batch (typically 1-50 units). The cost per part remains relatively constant regardless of the quantity, as there are no economies of scale from tooling.

-

CNC Machining: CNC machining involves significant upfront setup costs, including CAM programming, machine setup, and fixturing. This makes producing a single part quite expensive. However, once the machine is programmed and set up, producing subsequent parts is much faster and cheaper. As a result, CNC machining becomes more economical as production volume increases. For medium to high volumes, the initial setup cost is amortized over many parts, leading to a lower per-part cost compared to 3D printing.

| Production Volume | Most Cost-Effective Method | Reason |

|---|---|---|

| 1-10 Parts (Prototyping) | 3D Printing | Low startup costs and no tooling required. |

| 10-200 Parts (Low Volume) | Competitive | The choice depends on part complexity and material. CNC becomes more viable. |

| 200+ Parts (High Volume) | CNC Machining | High setup costs are distributed, making the per-part cost significantly lower. |

Production Speed and Lead Times for Custom Machined Plastic Parts: Prototyping vs. Mass Production

Turnaround time is often a critical factor, especially during the product development and prototyping phases.

-

Prototyping Speed: For creating one-off prototypes or iterating on a design, 3D printing is almost always faster. A part can often be printed overnight, allowing designers and engineers to have a physical model in their hands the next day. This rapid feedback loop is invaluable for agile product development. CNC machining requires a longer lead time for initial setup and programming, with typical turnarounds of several days to over a week.

-

Production Speed: When it comes to producing larger quantities of parts, the tables turn. While a 3D printer takes the same amount of time to produce the tenth part as it did the first, a CNC machine, once set up, can produce parts much more rapidly. For mass production, CNC machining's speed per part is significantly faster than 3D printing, making it the clear choice for high-volume manufacturing.

Scalability and Repeatability in Manufacturing Custom Machined Plastic Parts

The ability to consistently produce identical parts and scale up production is a key manufacturing consideration.

-

CNC Machining: Repeatability is a major strength of CNC machining. Once a program is perfected, the machine can produce thousands of parts with extremely high precision and consistency, with tolerances that are often difficult for 3D printing to match. This makes it an ideal process for scaling from low-volume to mass production while maintaining strict quality control.

-

3D Printing: While modern industrial 3D printers offer good repeatability, there can be slight variations between prints due to factors like machine calibration, material batches, and environmental conditions. The layer-by-layer nature of the process can make holding extremely tight tolerances consistently across large batches more challenging than with CNC. However, for many applications, the repeatability of professional 3D printing systems is more than adequate. Scaling up production in 3D printing typically involves using multiple machines in parallel (a "print farm") rather than increasing the speed of a single machine.

Strategic Selection: When to Choose 3D Printing or CNC Machining for Your Custom Plastic Parts

The decision between 3D printing and CNC machining isn't about which technology is "better" overall, but which is the right tool for the specific job at hand. By understanding the ideal scenarios for each, you can optimize your manufacturing strategy for cost, speed, and quality.

Identifying Ideal Scenarios for Rapid Prototyping and Complex Custom Plastic Parts

3D printing is often the superior choice in situations where speed, design freedom, and cost-effectiveness for low volumes are the primary drivers.

Choose 3D Printing When:

- You need rapid prototypes: For concept models, form-and-fit testing, and quick design iterations, nothing beats the speed of 3D printing. Getting a physical part in hand within hours or a day is a significant advantage.

- Your design has high geometric complexity: If the part includes intricate internal channels, complex organic shapes, or consolidated assemblies, 3D printing is the only feasible option. It fabricates complexity at no additional cost.

- You're producing a single part or a very small batch: For quantities under 10-50 pieces, 3D printing is almost always more cost-effective due to the absence of setup and tooling costs.

- The part requires lightweighting: Additive manufacturing excels at creating parts with internal lattice structures, which reduce material usage and weight without sacrificing structural integrity in key areas.

- You need flexible or rubber-like parts: Materials like TPU are perfectly suited for 3D printing, allowing for the creation of flexible components that are difficult to machine.

Optimizing for Precision, High-Volume, and Robust Custom Machined Plastic Parts

CNC machining remains the gold standard for applications where strength, precision, and scalability are non-negotiable.

Choose CNC Machining When:

- You require high dimensional accuracy and tight tolerances: For parts that need to fit together perfectly or meet stringent specifications, the precision of CNC machining is unmatched.

- Superior material properties are critical: If the part will be subjected to high mechanical stress, impact, or extreme temperatures, the isotropic strength of a CNC-machined solid plastic block is essential. Machined parts are inherently stronger and more durable.

- A smooth surface finish is required: CNC provides an excellent surface finish straight off the machine, which is crucial for aesthetic parts or functional surfaces.

- You are moving into medium to high-volume production: For batches of hundreds or thousands of parts, CNC machining offers a lower cost per part and faster production speeds, making it ideal for scaling up.

- The material you need is not available for 3D printing: CNC machining supports a broader range of engineering plastics, giving you more options to meet specific performance requirements.

The Power of a Hybrid Approach for Custom Plastic Parts: Combining Both Technologies

Savvy product developers know that the smartest approach is often not an "either/or" choice but a "both/and" strategy. By leveraging the strengths of each technology at different stages of the product lifecycle, you can create a highly efficient and effective manufacturing workflow.

A typical hybrid approach might look like this:

- Prototyping Phase: Use 3D printing (e.g., SLA or FDM) to rapidly create and iterate on multiple design concepts. This is fast, cheap, and allows for extensive testing of form and fit.

- Functional Testing Phase: Once the design is refined, use a more robust additive method (like SLS) or even CNC machining to create a high-fidelity functional prototype. This part can be made from a material closer to the final product's specifications and can undergo rigorous real-world testing.

- Production Phase: For the final production run, transition to CNC machining to achieve high precision, excellent material properties, and the economies of scale needed for larger volumes.

This hybrid model allows you to innovate quickly with the flexibility of 3D printing while ensuring the final product meets the highest standards of quality and durability through CNC machining.

Finally, the choice between 3D printing and CNC machining for custom machined plastic parts hinges on a careful evaluation of project requirements, including design complexity, material needs, production volume, budget, and desired turnaround time. Both technologies offer unique advantages that, when understood comprehensively, can lead to successful product development. By understanding the distinct characteristics of each process, we can make informed decisions that optimize efficiency, cost-effectiveness, and the quality of our custom machined plastic parts. Whether it's the rapid iteration of 3D printing or the precision of CNC machining, the right choice empowers us to innovate and deliver superior products.

For all your custom plastic part needs, SOMI Custom Parts offers both 3D printed components and precision CNC machining services. As a manufacturer and supplier with extensive SOMI CNC Machining Capability and advanced SOMI 3D Printing Capability, we provide OEM customization services to printing equipment factories and CNC machining facilities worldwide, ensuring high-quality solutions for every project. We encourage you to share your thoughts on these technologies and how you use them in your own projects.