A Complete Guide to CNC Machining Tolerances: From Standards to Precision

In the world of precision manufacturing, success is measured in micrometers. For industries like aerospace, medical, and automotive, the ability to produce parts that fit and function flawlessly is not just a goal—it's a requirement. This is where Computer Numerical Control (CNC) machining excels, offering unparalleled accuracy and repeatability. However, the true key to unlocking its potential lies in understanding and correctly applying CNC machining tolerances.

Tolerance refers to the acceptable deviation in a physical dimension. Since achieving absolute perfection is impossible in any manufacturing process, tolerances define a range of acceptable variation that ensures a part will function as intended. This guide provides a comprehensive overview of CNC machining tolerances, covering the fundamental concepts, influencing factors, and best practices for achieving precision.

Accuracy vs. Precision: What's the Difference?

Before diving into tolerances, it's crucial to distinguish between two often-confused terms: accuracy and precision.

- Accuracy is how close a measurement is to the true or specified value. In machining, it means how well the machine creates a part that matches the blueprint dimensions.

- Precision is the repeatability of a process. It measures how consistently the machine can produce identical parts, regardless of whether they match the target dimension.

Imagine a target. An accurate shooter hits the bullseye. A precise shooter hits the same spot repeatedly, even if that spot isn't the bullseye. In CNC machining, the goal is to be both accurate and precise—consistently hitting the exact dimensional target.

Understanding Tolerance Notation

Tolerance is typically expressed as a "±" value, indicating the allowable variance from a nominal dimension. For example, a dimension of 25.00 mm ±0.05 mm means the final part can measure anywhere between 24.95 mm and 25.05 mm and still be acceptable. Tolerances can be defined in several ways:

- Bilateral Tolerance: Variation is permitted on both sides of the nominal size (e.g., ±0.05 mm).

- Unilateral Tolerance: Variation is only allowed in one direction (e.g., +0.10/-0.00 mm).

- Limit Tolerances: Specifies the maximum and minimum permissible dimensions directly, instead of using a ± symbol.

The Importance of Tolerances in Manufacturing

Properly defined tolerances are critical for several reasons:

- Functionality and Fit: They ensure that individual components of an assembly fit together correctly. This is non-negotiable in complex systems like engines or medical devices.

- Performance: In high-performance applications, even microscopic deviations can impact efficiency, reliability, and safety.

- Interchangeability: Standardized tolerances allow parts made in different locations or at different times to be interchangeable, simplifying assembly and repairs.

- Cost Control: Tighter tolerances are more expensive to achieve. Defining realistic tolerances based on function prevents over-engineering and manages production costs.

Standard CNC Machining Tolerances

While every project has unique requirements, industry standards provide a baseline. A common standard tolerance for CNC machining is approximately ±0.005 inches (±0.127 mm). For parts requiring higher precision, tolerances can be tightened to ±0.001 inches (±0.025 mm) or even less.

Extremely tight tolerances, sometimes as low as ±0.0002 inches (±0.005 mm), are achievable but demand specialized equipment, controlled environments, and rigorous quality control processes.

The Role of ISO 2768

To simplify technical drawings and create a universal language for tolerances, the International Organization for Standardization (ISO) developed the ISO 2768 standard. This standard provides a set of general tolerances for linear, angular, and geometric features if no specific tolerance is indicated on the drawing.

ISO 2768 is divided into two parts:

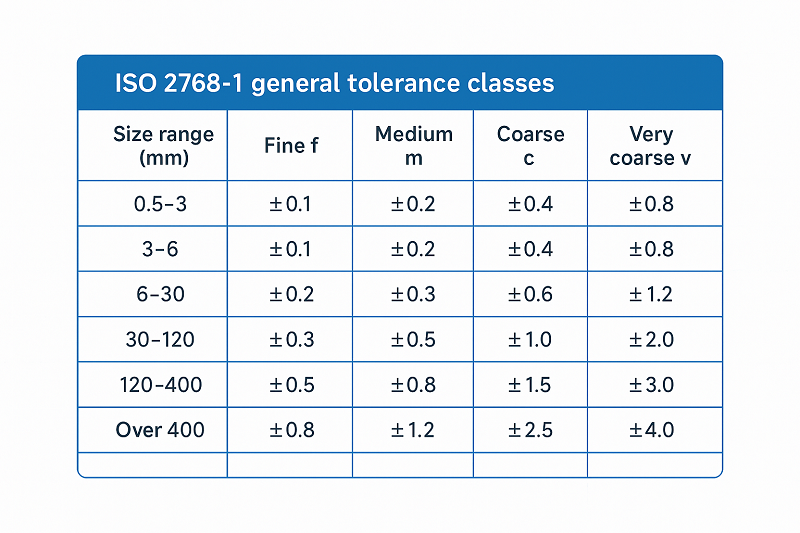

- ISO 2768-1: Covers general tolerances for linear and angular dimensions, categorized into classes: fine (f), medium (m), coarse (c), and very coarse (v).

- ISO 2768-2: Deals with general geometrical tolerances like flatness, straightness, and perpendicularity, categorized into classes H, K, and L. Most machine shops adhere to ISO 2768-m (medium) as their default standard unless otherwise specified by the client.

Key Factors That Influence Machining Accuracy

Achieving tight tolerances is not automatic. It depends on controlling a variety of interconnected factors:

- Machine Capability and Rigidity: The build quality, structural stiffness, and condition of the CNC machine itself are foundational. Factors like spindle runout, backlash in the drive system, and thermal stability directly impact accuracy.

- Cutting Tool Selection and Wear: The right tool for the material is essential. Tool material, coating, and geometry all matter. As a tool wears down, its cutting effectiveness diminishes, leading to dimensional inaccuracies.

- Material Properties: The workpiece material's hardness, thermal stability, and machinability affect how it responds to the cutting process. Softer materials may deform, while harder materials can increase tool wear.

- Fixturing and Workholding: The workpiece must be held securely and without distortion. Poor clamping can lead to vibration, movement, and inaccurate cuts.

- Environmental Conditions: Temperature fluctuations in the workshop can cause both the machine and the workpiece to expand or contract, a phenomenon known as thermal drift. Maintaining a climate-controlled environment is crucial for high-precision work.

- Operator Skill and Programming: The expertise of the machinist in setting up the machine, optimizing toolpaths in the CAM software, and making real-time adjustments is invaluable.

Achieving Tighter Tolerances: Best Practices

When a project demands precision beyond the standard, several strategies can be employed:

- Use High-Precision Equipment: Start with a high-end, well-maintained CNC machine known for its accuracy.

- Implement Strict Quality Control: Use advanced measuring tools like Coordinate Measuring Machines (CMMs) to verify dimensions during and after machining.

- Control the Environment: Operate in a temperature- and humidity-controlled facility to minimize thermal expansion.

- Optimize Cutting Strategies: Use appropriate speeds and feeds, manage tool life with automatic replacement schedules, and design toolpaths that minimize vibration and heat buildup.

- Perform Regular Calibration: Use laser interferometers and ballbar tests to regularly calibrate the machine and compensate for any positioning errors.

- Clear Communication: Ensure that all tolerance requirements are clearly communicated to the machine shop on technical drawings using standards like GD&T (Geometric Dimensioning and Tolerancing).

The Cost of Tight Tolerances

The relationship between tolerance and cost is exponential. The tighter the tolerance, the higher the manufacturing cost. This is due to the need for more advanced machinery, increased setup and cycle times, higher-quality tooling, and more intensive quality inspection. Therefore, it's essential for designers to specify the tightest tolerances only where they are functionally necessary. Over-tolerancing a non-critical feature adds unnecessary cost and complexity to a project.

Standard Tolerances by CNC Process

Tolerances can vary based on the specific CNC machining process. Here is a general overview:

| Machining Process | Typical Standard Tolerance | Achievable Tight Tolerance |

|---|---|---|

| CNC Milling | ±0.005" / ±0.127 mm | ±0.001" / ±0.025 mm |

| CNC Turning | ±0.005" / ±0.127 mm | ±0.0005" / ±0.013 mm |

| CNC Grinding | ±0.0002" / ±0.005 mm | ±0.0001" / ±0.0025 mm |

| Electrical Discharge (EDM) | ±0.0005" / ±0.013 mm | ±0.0001" / ±0.0025 mm |

Note: These values are general guidelines and can vary based on material, part complexity, and machine capabilities.

Conclusion: A Partnership for Precision

Understanding and effectively managing CNC machining tolerances is a cornerstone of modern manufacturing. It is a balancing act between design requirements, process capabilities, and cost. While it may seem complex, it boils down to a clear principle: specify what is necessary, control the variables, and verify the results. By fostering clear communication between designers and machinists and adhering to the best practices outlined in this guide, you can consistently achieve high-quality, functional, and cost-effective parts that meet the most demanding specifications.